Large-sized ozone gas generator

A gas generator and ozone technology, applied in the direction of ozone preparation, etc., can solve problems such as hindering heat dissipation, reducing ozone efficiency, electrode damage, etc., and achieve the effects of promoting mutual diffusion, good cooling effect, and high ozone production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

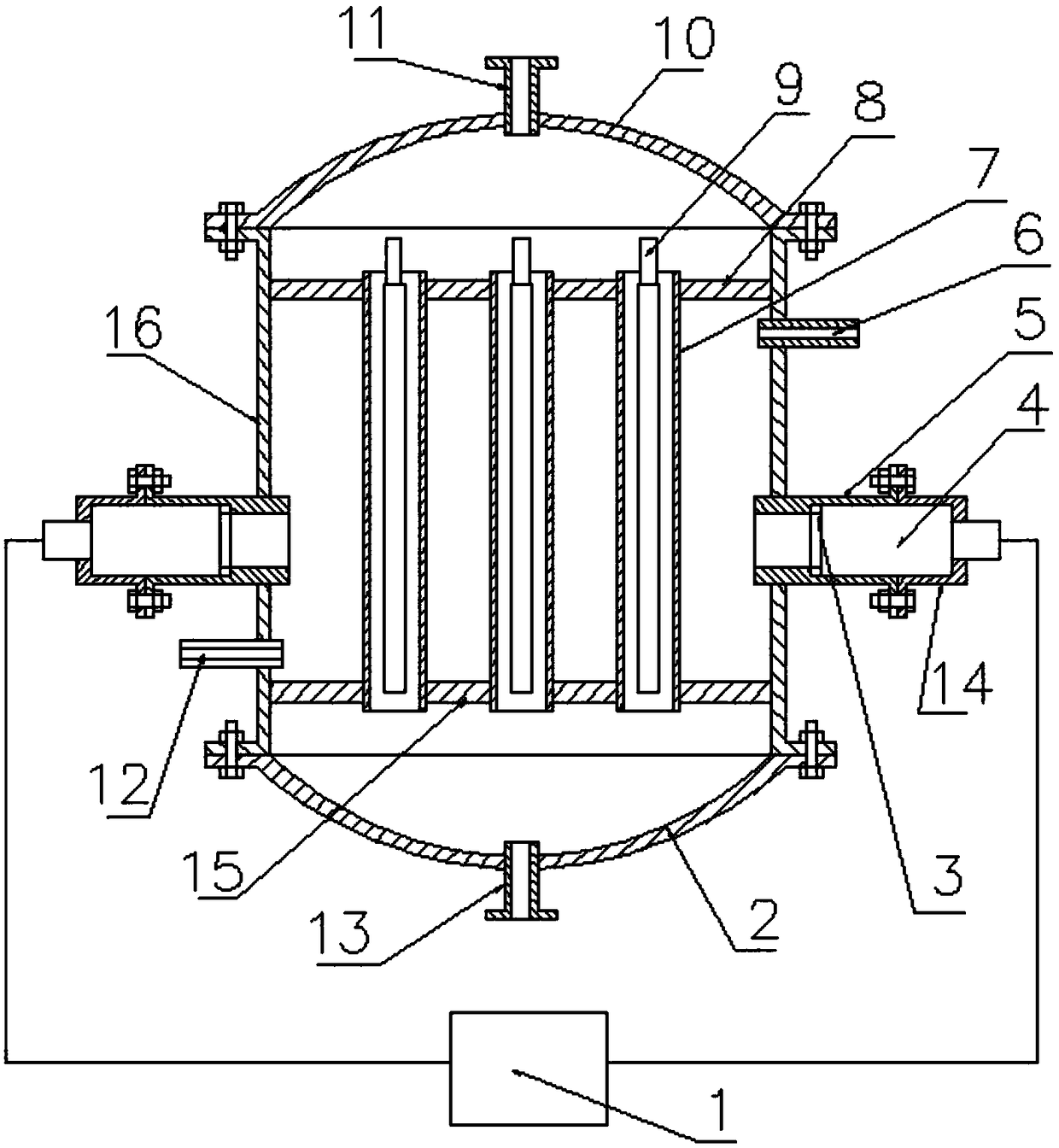

[0009] A large-scale ozone gas generator, which includes an ultrasonic generating circuit module (1), a lower head (2), a sealing ring (3), an ultrasonic transducer (4), a short round tube (5), and a water outlet joint (6), stainless steel pipe (7), upper blocking plate (8), inner electrode (9), upper head (10), air inlet joint (11), water inlet joint (12), air outlet joint (13 ), a fixing device (14), a lower blocking plate (15), and a barrel body (16). An upper blocking plate (8) and a lower blocking plate (15) are respectively arranged at the upper and lower ports of the barrel body (16), and several The stainless steel tube (7) penetrates the upper blocking plate (8) and the lower blocking plate (15) and is welded together with the upper blocking plate (8) and the lower blocking plate (15) at the end, and is set in each stainless steel tube (7) An inner electrode (9), the inner electrode (9) and the stainless steel pipe (7) should be reliably fixed, and an upper head ( 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com