Sunflower-shaped cable dome structure

A cable dome and sunflower technology, which is applied in the field of sunflower-shaped cable dome structures, can solve the problems of accelerated structural displacement increase, easy withdrawal of notches, and increased internal force of components, achieving light weight, fewer structural components, and improved bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

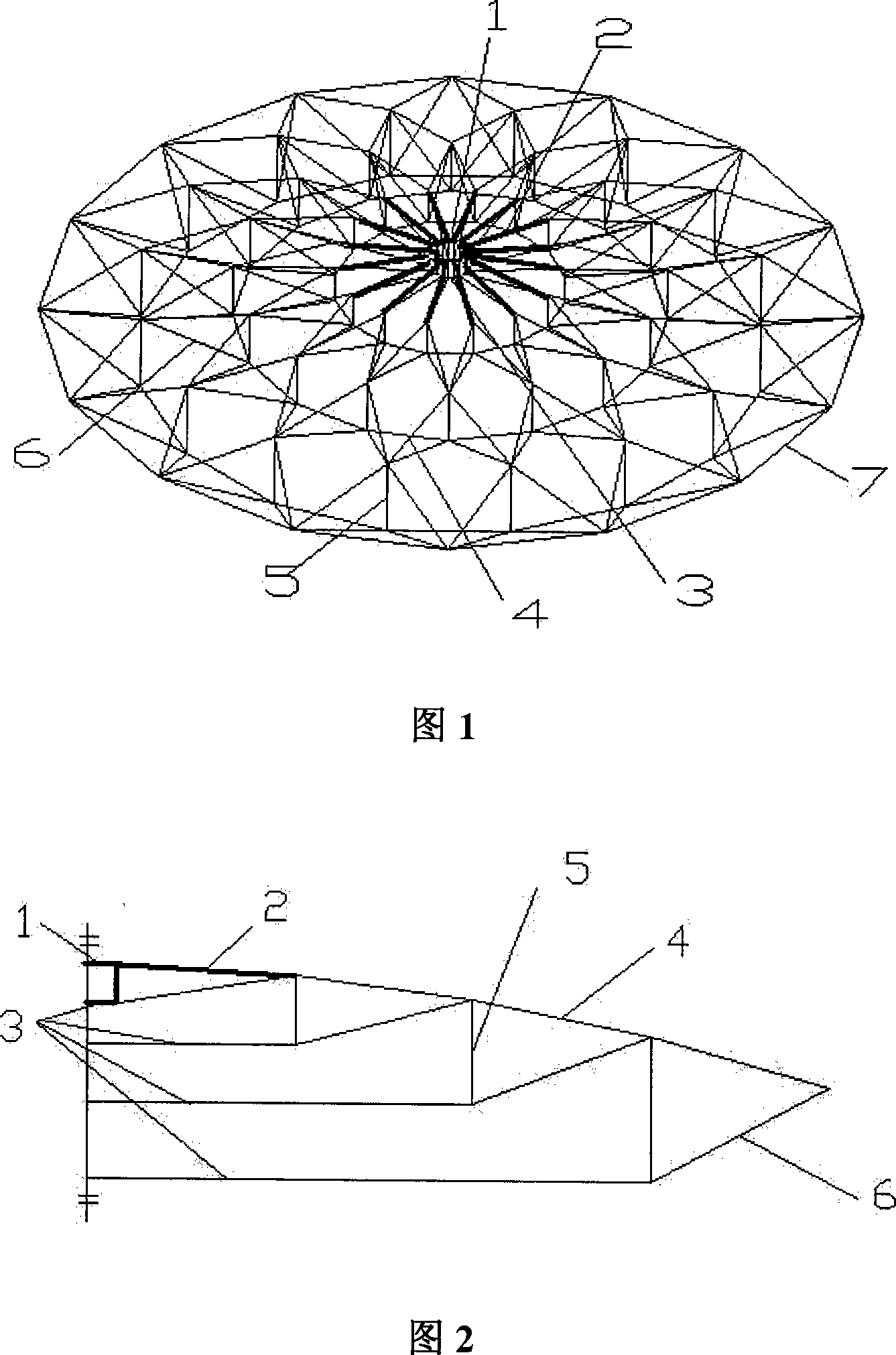

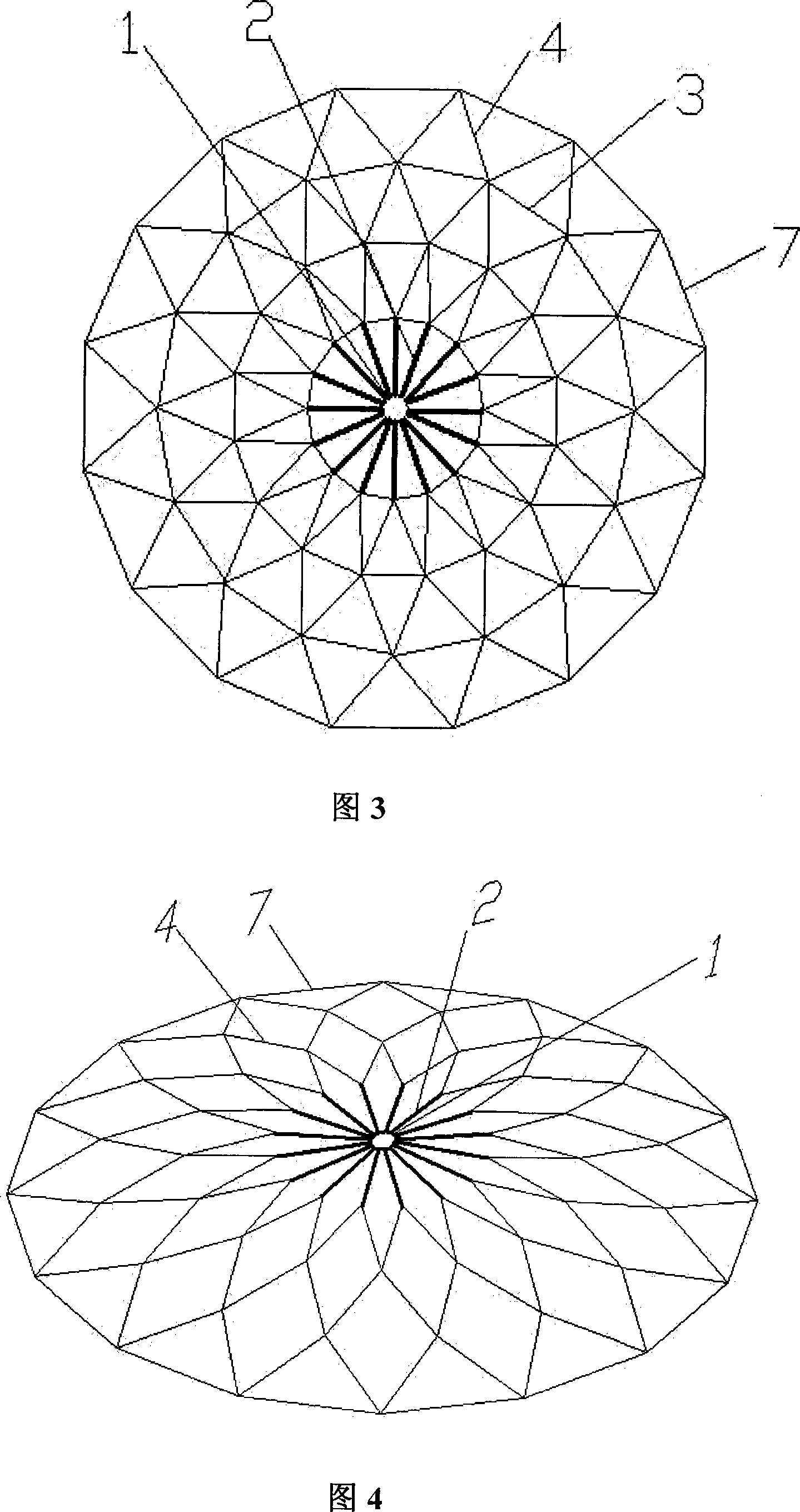

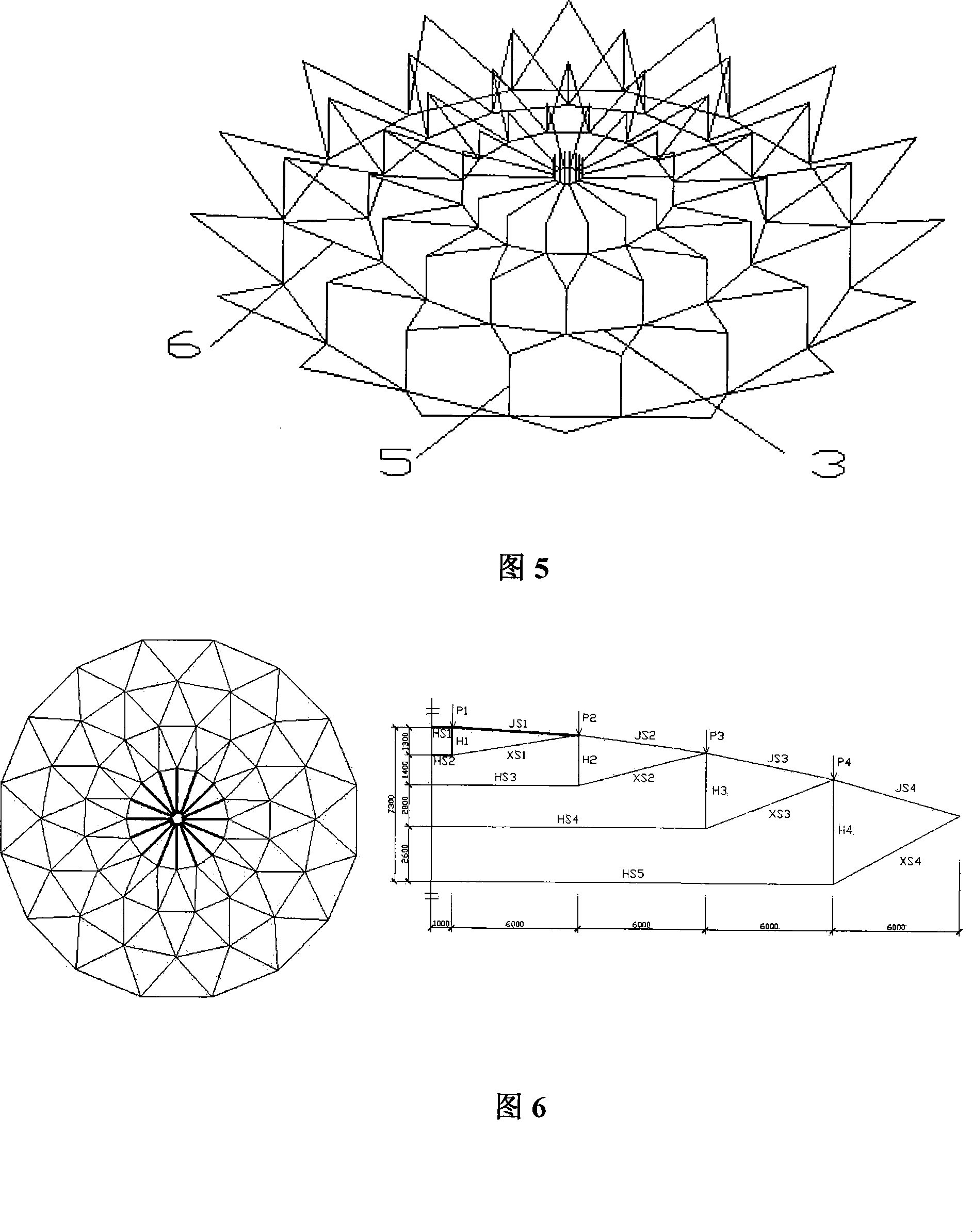

[0019] A sunflower-shaped cable dome structure has a central inner ring beam 1, stiffening rods 2, ring cables 3, ridge cables 4, vertical struts 5, oblique cables 6 and side ring beams 7, a central inner ring beam 1, stiffening Rods 2, notches 4 and side ring beams 7 form a sunflower-shaped grid, one end of the stiff bar 2 is hinged to the central inner ring beam 1, and the other end of the stiff bar 2 is hinged to one end of the innermost notochord 4, One end of the outermost ridge cable 4 is anchored to the side ring beam 7, the upper end of the vertical strut 5 is hinged to the ridge cable 4, the lower end of the vertical strut 5 is hinged to one end of the oblique cable 6 and the ring cable 3, and the other end of the oblique cable 6 It is hinged with the ridge cable 4, the outermost slanted cable 6 is anchored with the side ring beam 7, and the ring cable 3 is closed and arranged along the ring direction.

[0020] The stiff bar 2 is a stiff bar that bears tension and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com