A solar cell interconnection process

A solar cell and electrical interconnection technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as series impedance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

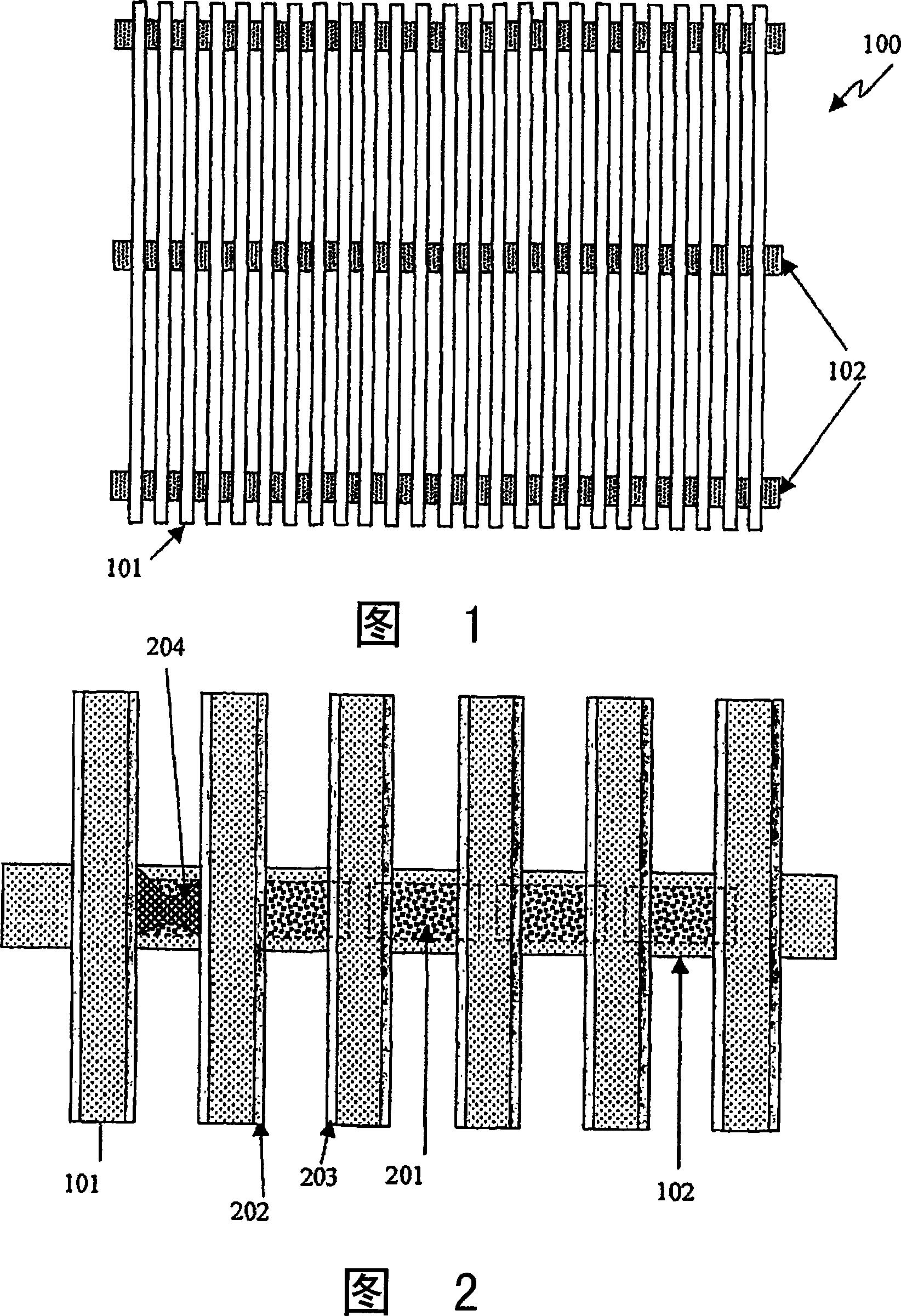

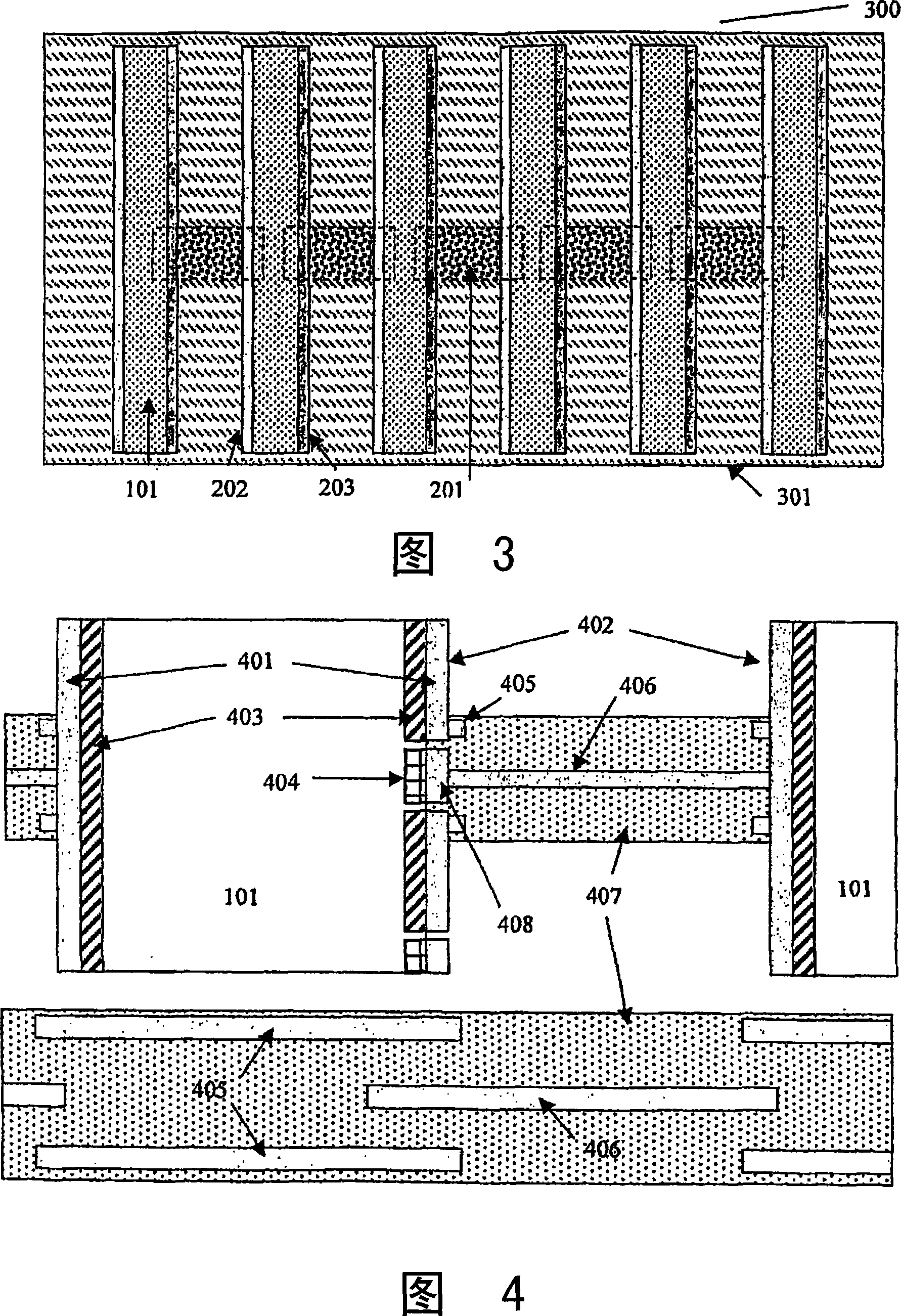

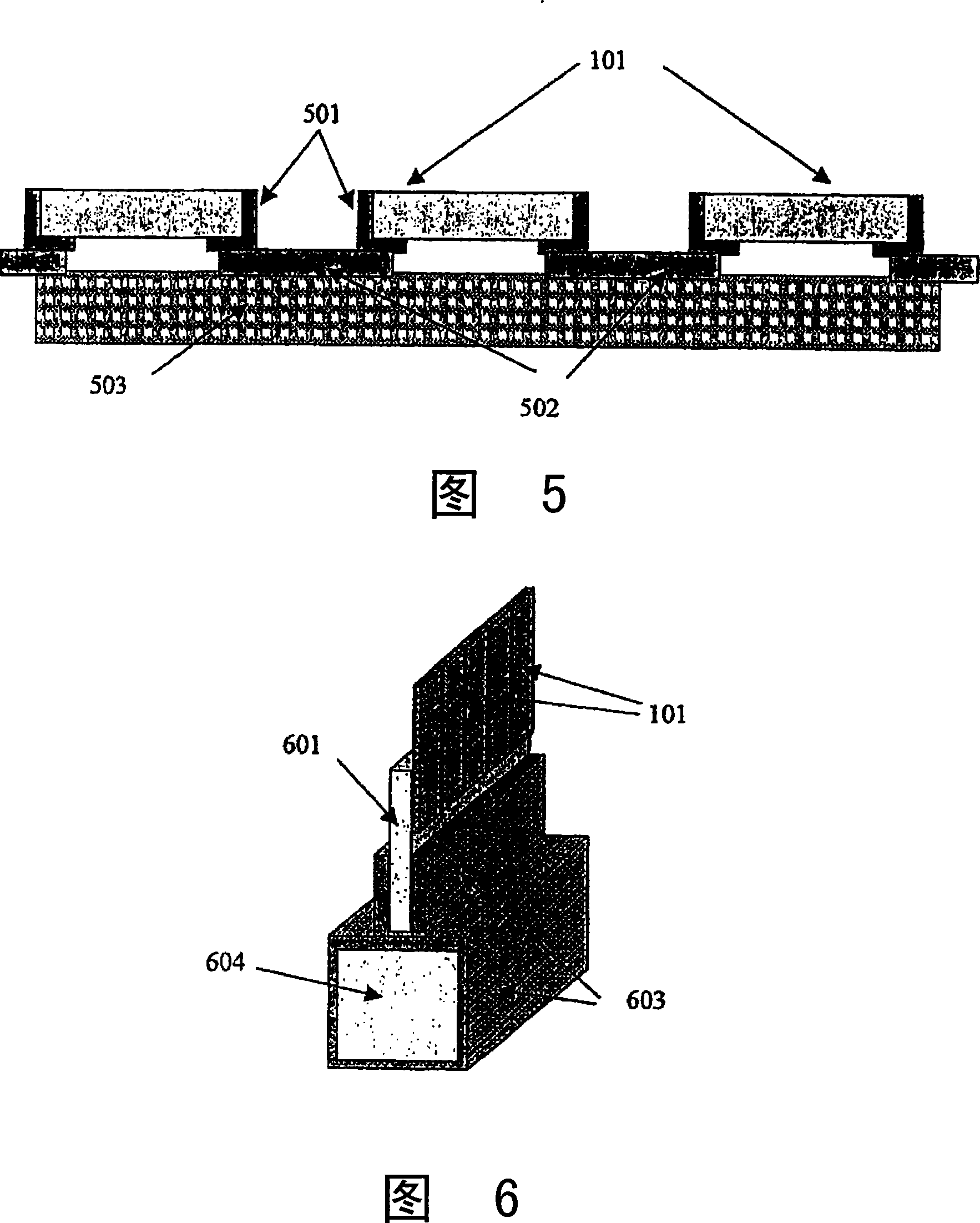

[0089] The process discussed below involves the use of elongated solar cells to form two products, elongated solar cell rafts for incorporation in a stationary collector solar power module; and elongated solar cells for application in collector reception Welded raft. The processes discussed in the formation of these two products can also be applied to the formation of flat panel solar cell welding rafts and flat panel solar cell welding boats with simple dimensional changes to the equipment used. The same provisions for internal interchange between the separation, handling and assembly methods, processes and products of flat solar cells and strip solar cells are also used for rafts, grid rafts and boats.

[0090] International patent application PCT / AU2005 / 001193 discusses a process for forming assemblies or submodules for elongated substrates. Such submodules facilitate the handling of elongated substrates that have been assembled into larger modules. In particular, such su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com