Feeding device of a powder compression molding machine

A technology of feeding device and compression molding machine is applied in the field of feeding device of powder compression molding machine and powder compression molding machine, which can solve the problems of affecting the yield of finished products, non-uniform workpiece size, affecting feeding stability, etc., so as to achieve high feeding stability. , high practicability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

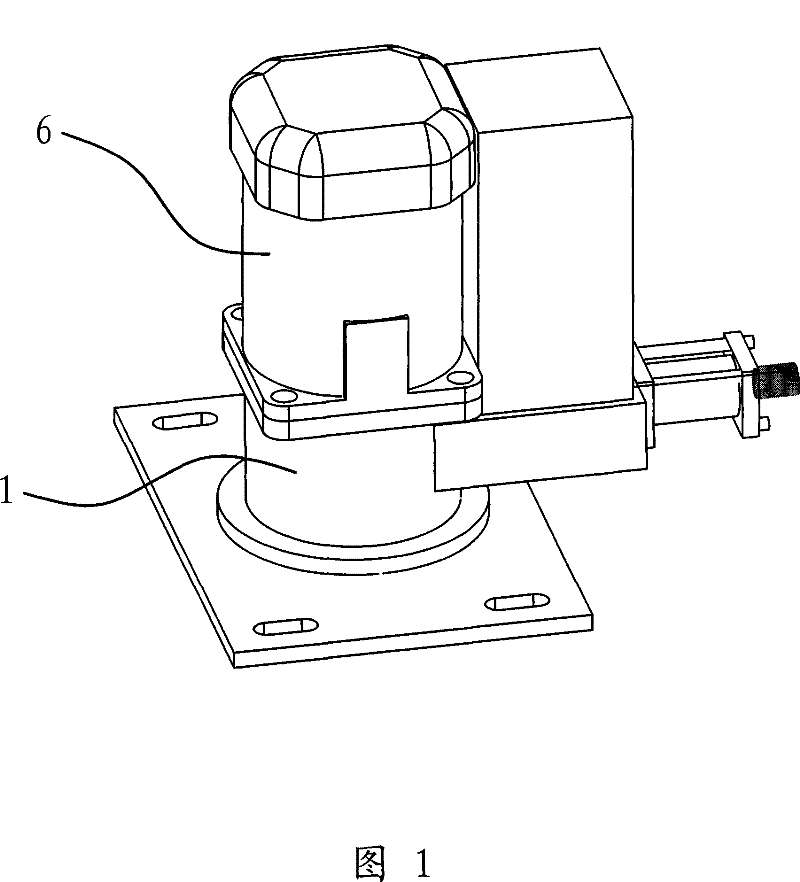

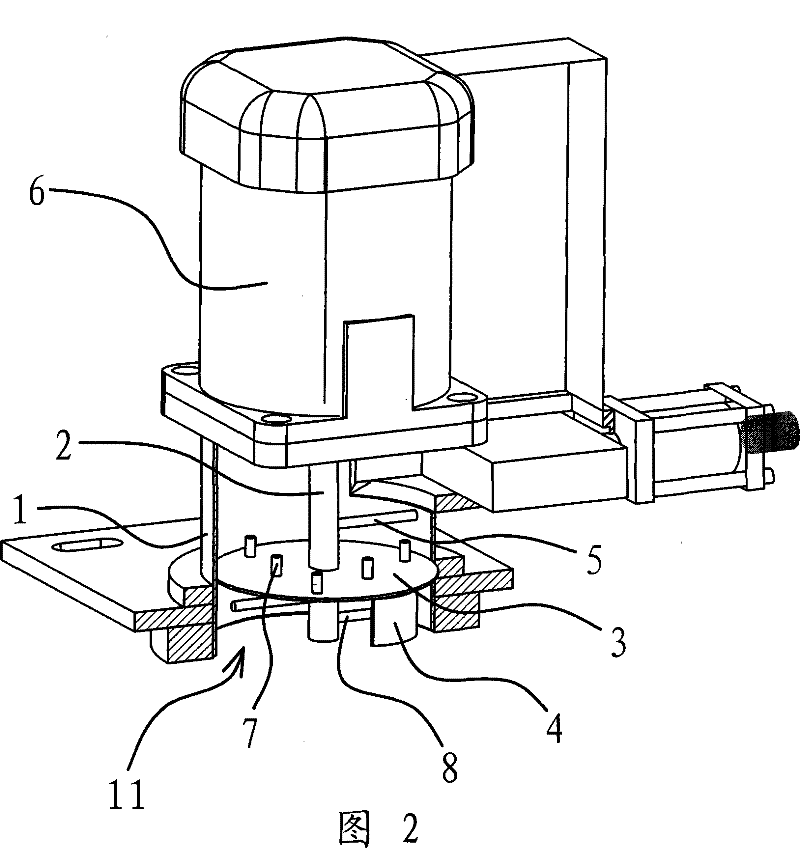

[0023] Such as figure 1 with figure 2 As shown, the feeding device of the powder compression molding machine includes a cylindrical feeding tube 1 , and the bottom of the feeding tube 1 has a discharge port 11 .

[0024] The device also includes a rotating shaft 2, the inner end of the rotating shaft 2 is located in the feeding cylinder 1, the outer end of the rotating shaft 2 stretches out from the top of the feeding cylinder 1, and the outer end of the rotating shaft 2 is fixed to the rotating shaft of the motor 6 even. Of course, according to the actual situation, in order to make the rotating shaft 2 reach multiple speeds, a speed change transmission device can also be arranged between the rotating shaft of the motor 6 and the rotating shaft 2 .

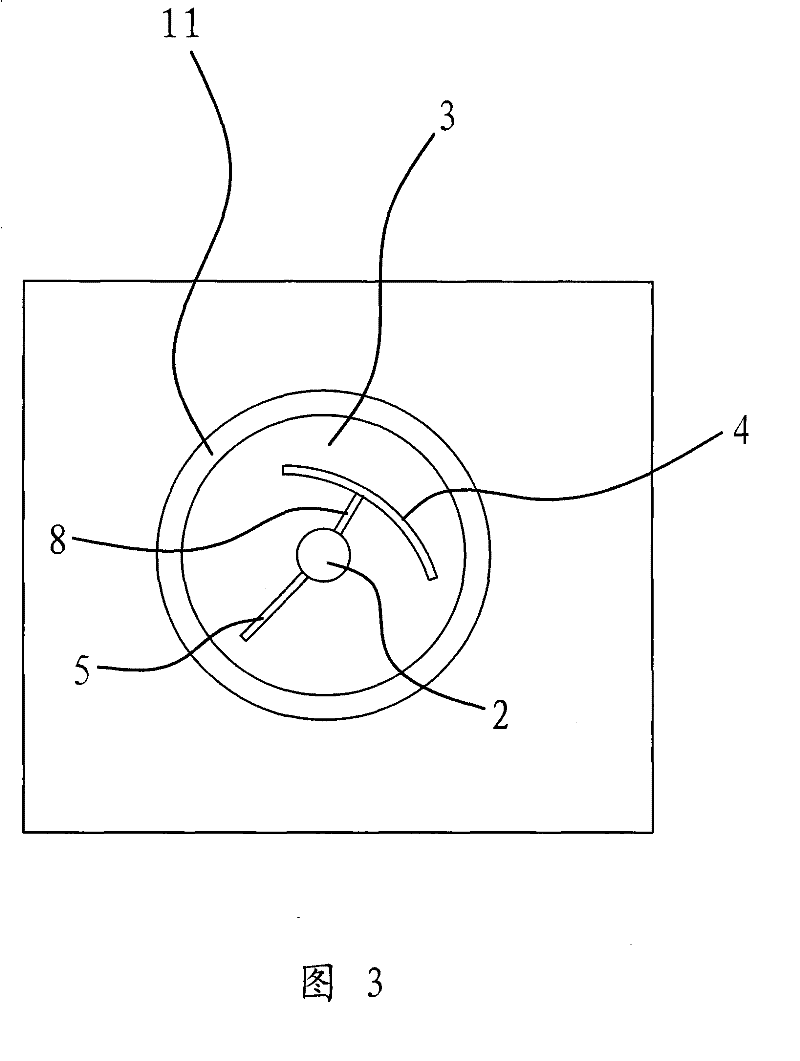

[0025] The inner end of the rotating shaft 2 is fixedly connected with the distribution pan 3 and the scraper plate 4 respectively from top to bottom, and several stirring teeth 5 are also fixed vertically at the inner end of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap