Method for enwinding spiral reinforcement on outer surface of stay cable after being winded with PVF fluoride membrane adhesive tape

A fluorinated membrane and spiral rib technology, applied in the field of bridge cables, can solve the bottleneck of anti-aging performance, can not give full play to the anti-wind, rain and vibration performance of stay cables, and fail to improve the anti-aging performance of high-density polyethylene, etc. problems, to achieve the effect of ensuring durability and suppressing wind and rain-induced vibration

Inactive Publication Date: 2008-07-30

JIANGSU FASTEN STEEL CABLE CO LTD

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The first method, although it can provide another layer of protection after the high-density polyethylene sheath is damaged, it fails to improve the aging resistance of high-density polyethylene. At present, the aging resistance of high-density polyethylene has always been a durabl

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

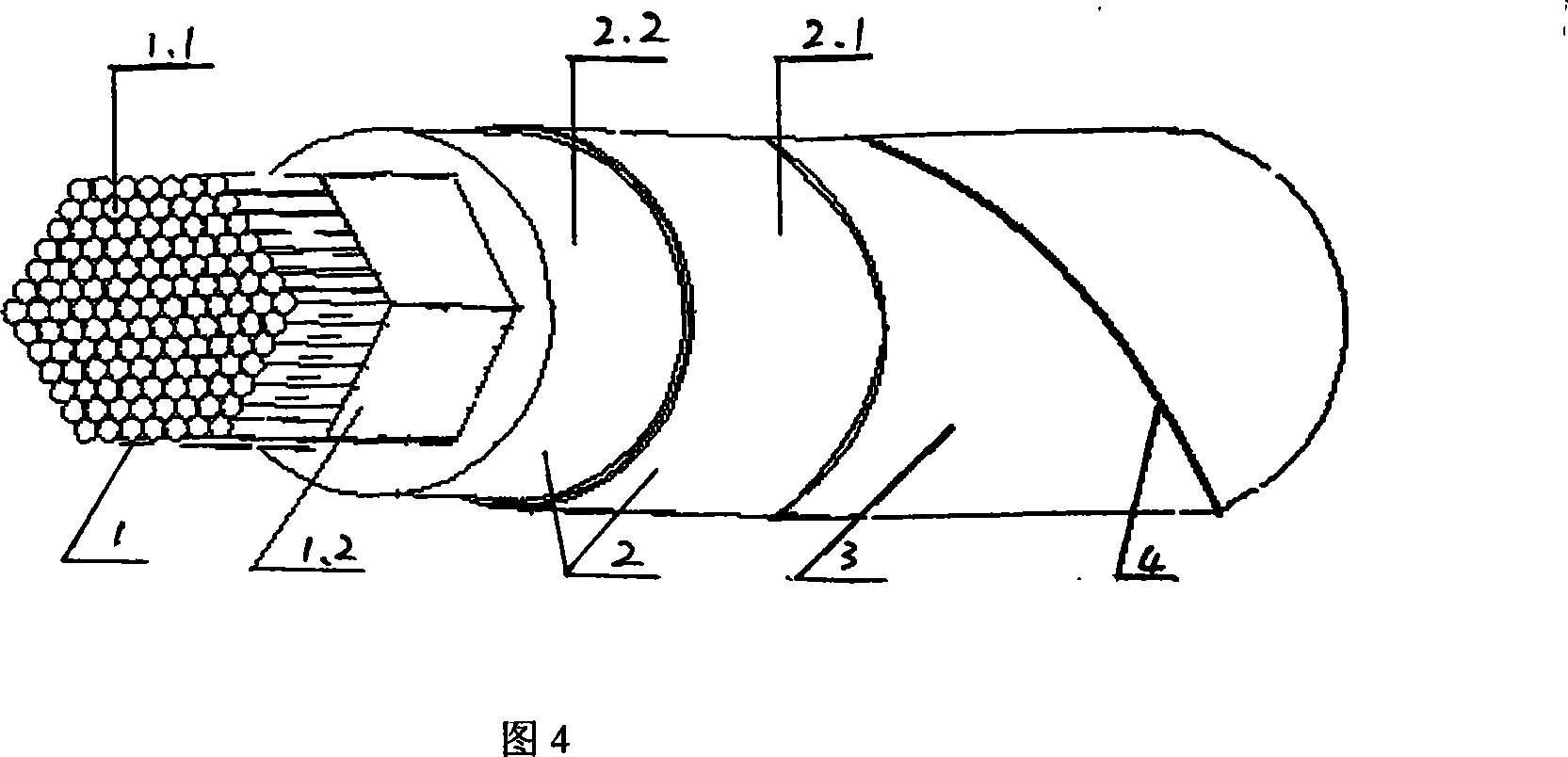

[0017] The present invention relates to a method for winding spiral ribs after wrapping PVF fluoride film tape on the outer surface of a cable stay cable, and the process steps of the method are as follows:

[0018] First heat-extrude high-density polyethylene for the steel wire bundles of the cable stays, then spirally wrap a layer of PVF fluorinated film protection tape, and finally wrap the spiral ribs outside the PVF tape, as shown in Figure 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention relates to a method for winding a spiral bar after the outer surface of a diagonal rope body is wound with a PVF fluorating film adhesive tape. The invention is characterized in that: the method has the technique steps as follows: the steel tendon of the diagonal rope is carried out hot extrusion high density polyethylene and then is wound and covered with a layer of PVF fluorating film protection adhesive tape in a spiral way, finally, the PVF adhesive tape is externally wound with the spiral bar. By adopting the method after being wound with the PVF fluorating film adhesive tape, the outer surface of the diagonal rope body is wound with the spiral bar, the invention not only exerts the excellent weatherability of the PVF adhesive tape, ensures the durability of the diagonal rope, but also at the same time makes use of the hydrophobic nature of the surface of the PVF adhesive tape and the wound spiral bar to well restrain the shock excitation of the diagonal rope for resisting wind and rain.

Description

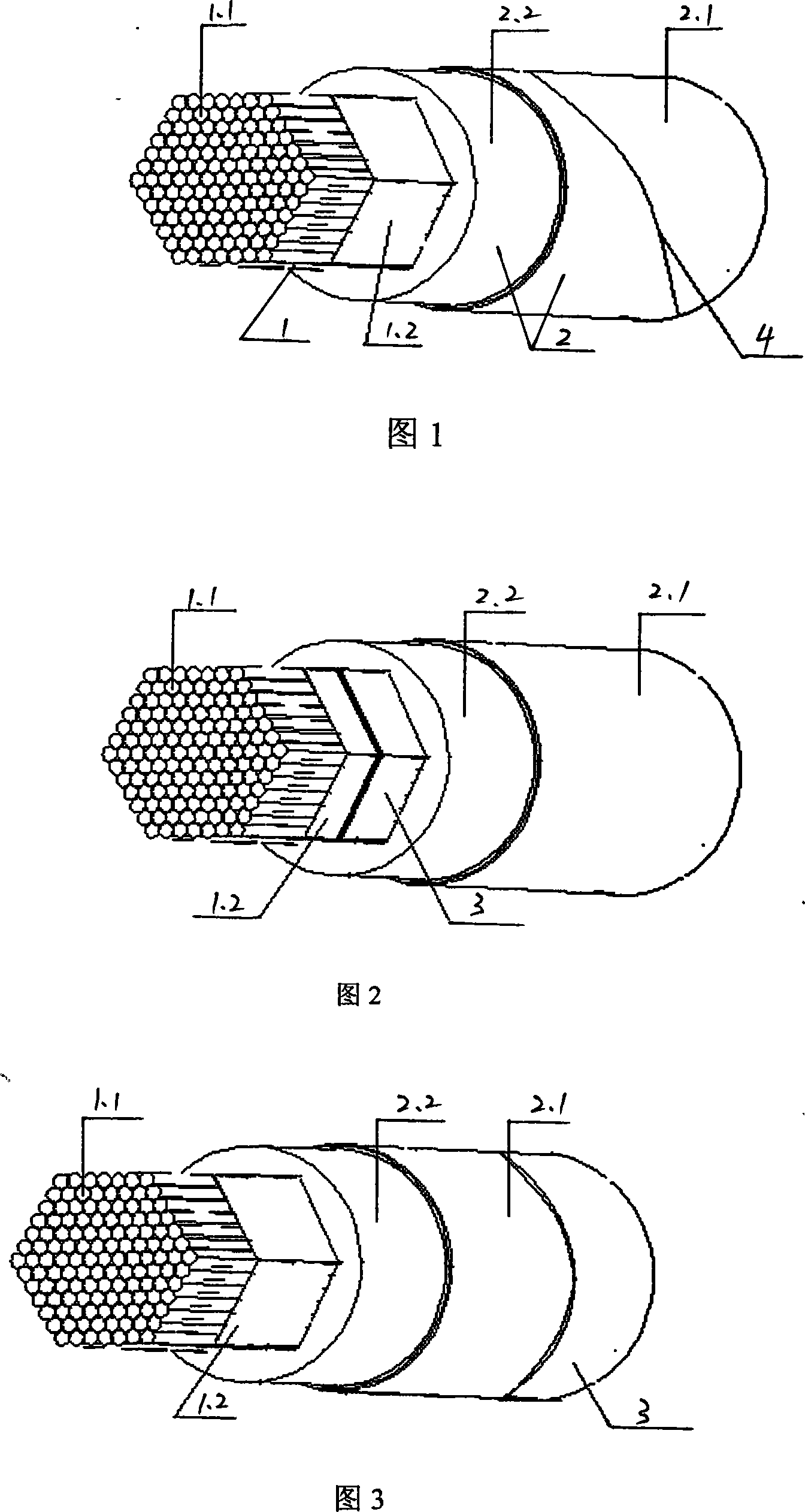

technical field [0001] The invention relates to a method for wrapping a PVF fluoride film tape on the outer surface of a cable-stayed cable and then wrapping a spiral rib. It belongs to the technical field of bridge cables. Background technique [0002] Usually, the anti-corrosion of stay cables is mainly protected by high-density polyethylene sheaths. At the same time, in order to solve the wind and rain-induced vibration of stay cables, aerodynamic measures such as embossing or winding spiral ribs are further adopted on the surface, as shown in Figure 1. However, in the past on many cable-stayed bridges, the high-density polyethylene sheaths of cable-stayed cables have cracked and damaged to varying degrees after being used for less than a few years. In order to further improve the anti-corrosion performance of cable-stayed cables, there are currently improvements The following two methods: [0003] 1. Wrap the parallel steel wire bundles with PVF fluorinated film tape b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): E01D19/00E01D19/16E01D11/04

Inventor 赵军宁世伟薛花娟陈灵芝周祝兵

Owner JIANGSU FASTEN STEEL CABLE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap