Opposed type light blocking equipment apparatus and method for making the same

A technology of photointerrupter and manufacturing method, applied in the direction of electrical components, pulse technology, electronic switches, etc., which can solve the problems of component damage, large cost, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

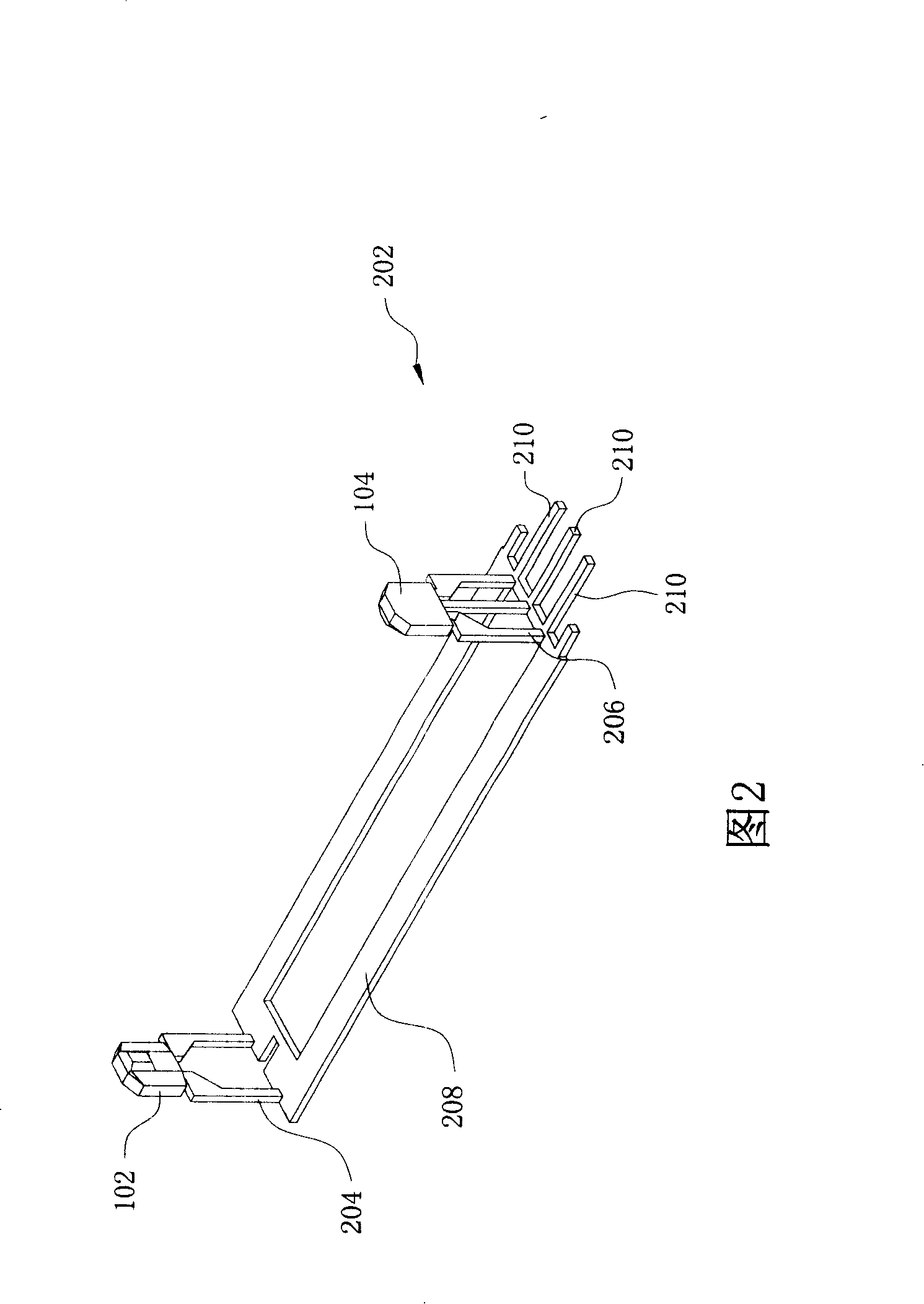

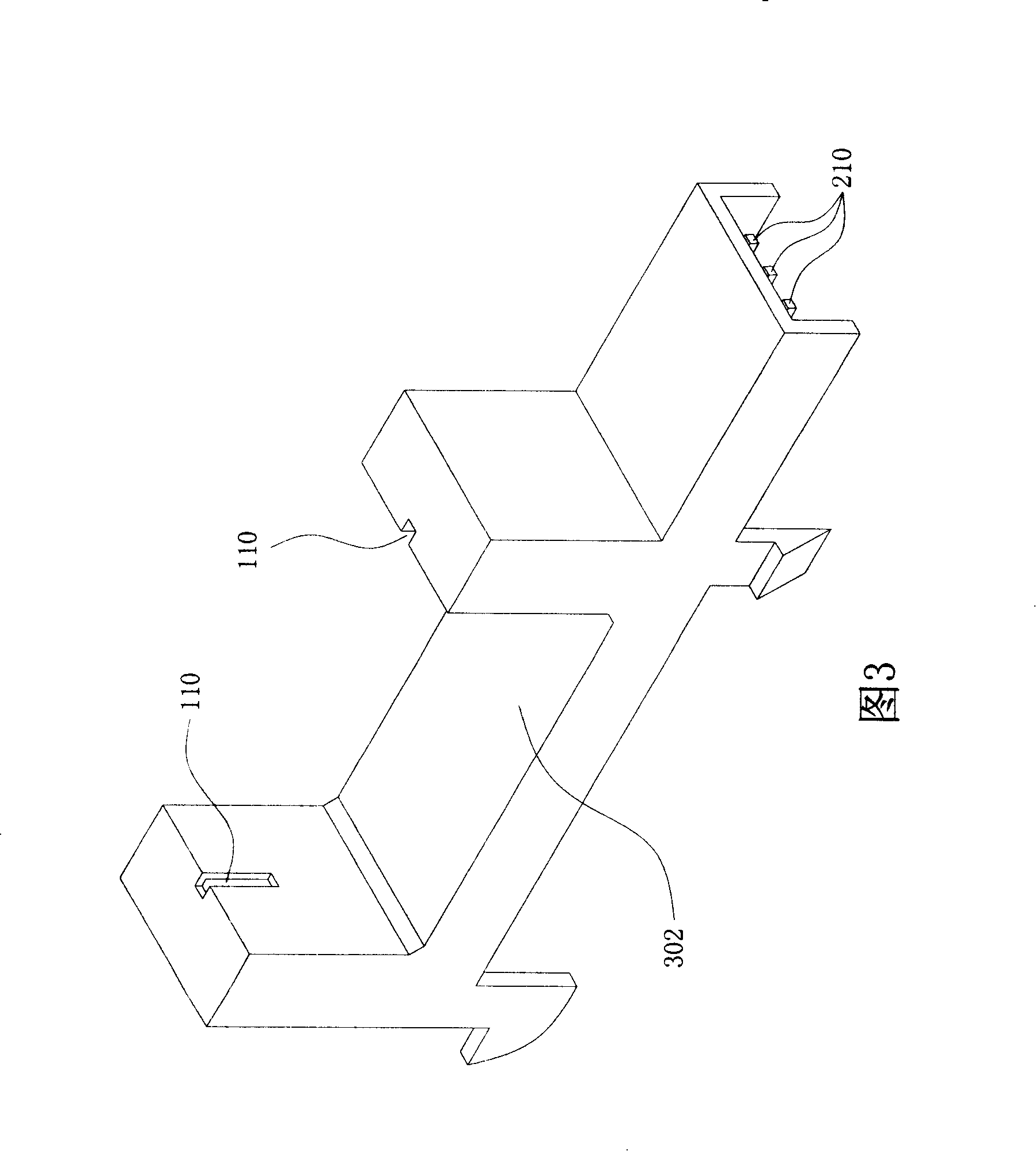

[0049] In the embodiment of the present invention, the signal source and the detector are directly packaged on the metal support, and the signal source and the detector are formed into a parallel opposing structure by bending. Anyone with ordinary knowledge in the technical field can cooperate with it If necessary, change the material, shape and related design parameters of the metal bracket to meet various application product specifications and cost considerations.

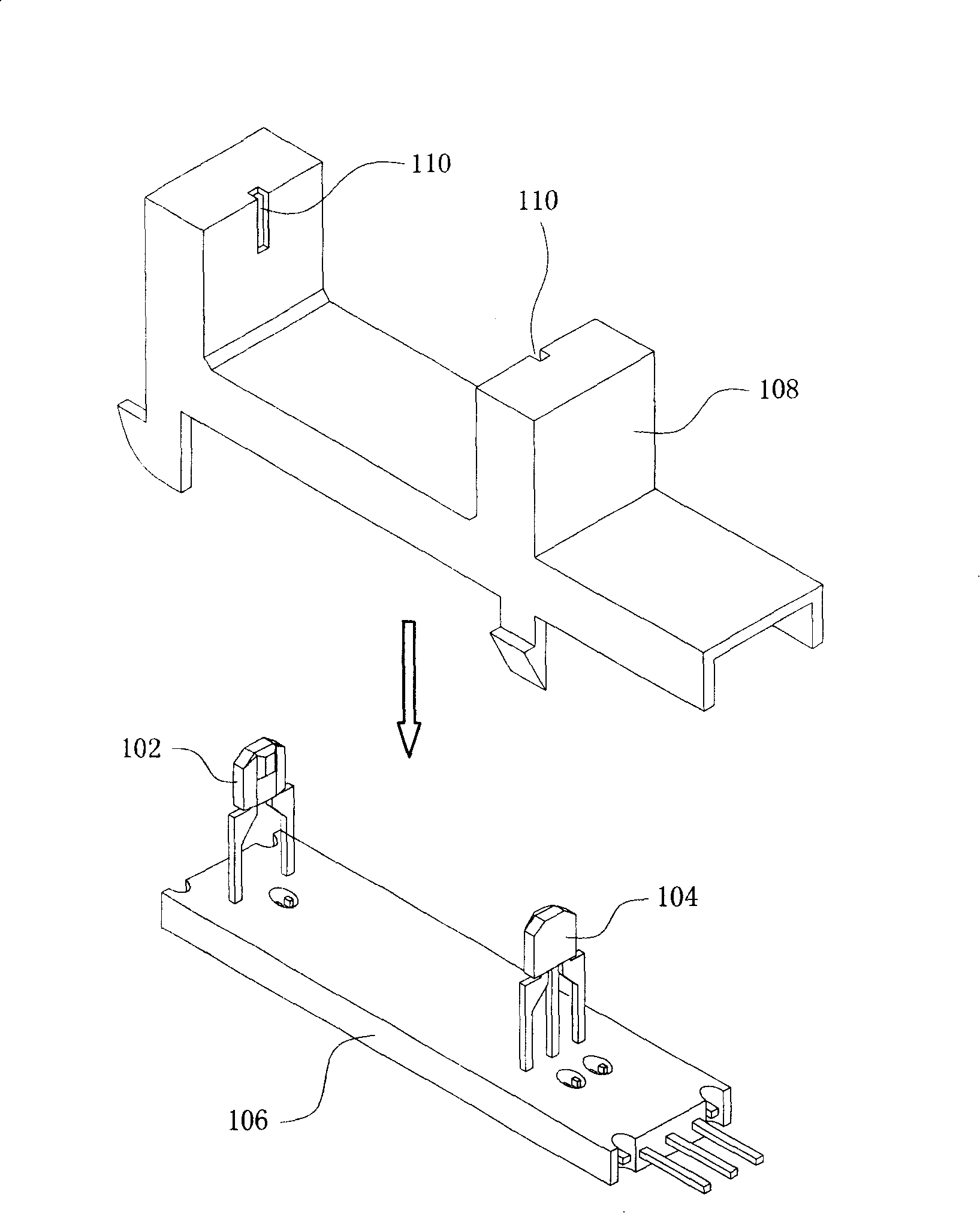

[0050] Please refer to figure 1 , an exploded view of the first embodiment of the present invention, the opposite photointerrupter in the figure can be divided into several parts, namely the signal source 102, the receiver 104, the housing 106 and the opposite light shield 108. The signal source 102 and the receiver 104 are in a parallel opposing structure, so that the receiver 104 can receive the signal sent by the signal source 102 . There are two holes 110 on the opposite shading cover 108, corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com