Compensation circuit for implementing contravariant welding machine electric power outputting current steadily

A compensation circuit and power output technology, applied in the field of compensation circuit, can solve the problems of high cost, easy introduction of interference, complicated circuit and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments.

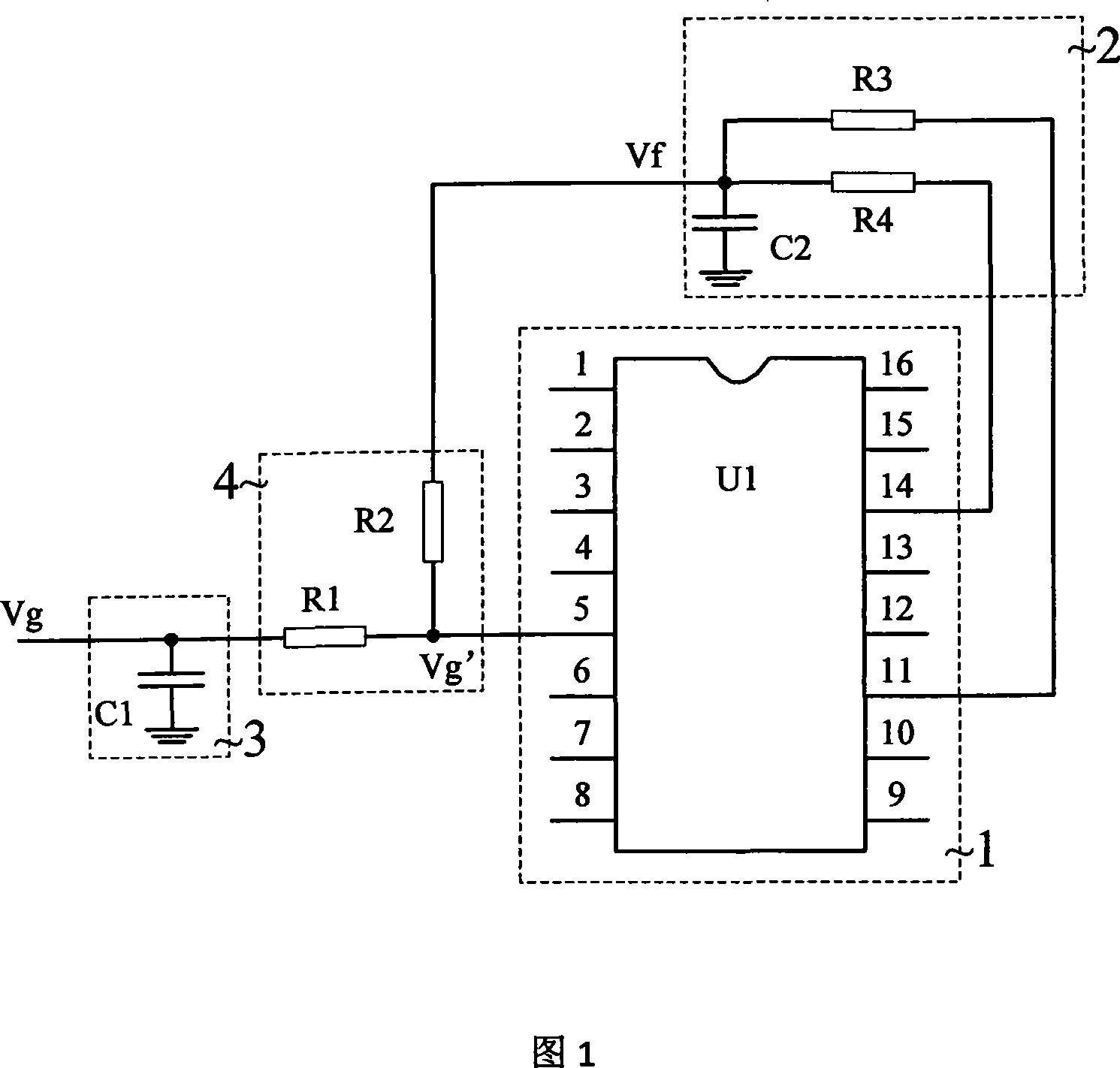

[0018] In Figure 1, it includes a pulse width modulator U 1 1. Pulse width modulator U 1 The pulse output terminal of 1 is connected to the driving pulse filter circuit 2, the driving pulse filter circuit 2 is connected to the compensation circuit 4, the compensation circuit 4 is connected to the current setting filter circuit 3, and the current setting filter circuit 3 is connected to the input current setting signal V g ; At the same time the compensation circuit 4 is also connected with the pulse width modulator U 1 1. The control end.

[0019] Pulse width modulator U 1 0Using current-type pulse width modulator.

[0020] Drive pulse filter circuit 2 uses resistor R 3 , R 4 And capacitance C 2 Composed of RC filter circuit.

[0021] Current given filter circuit 3 uses capacitor C 1 The capacitor filter circuit formed.

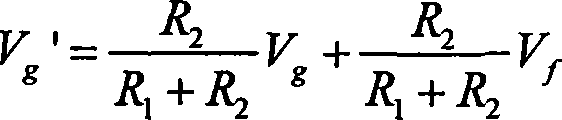

[0022] The compensation circuit 4 consists of tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com