Fish sizer

A filter and fish technology, applied in fish sorting, sieving, crustacean processing, etc., can solve the problems of increased volume, complex device structure, inability to perform rapid screening, etc., and achieve the effect of effective screening work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

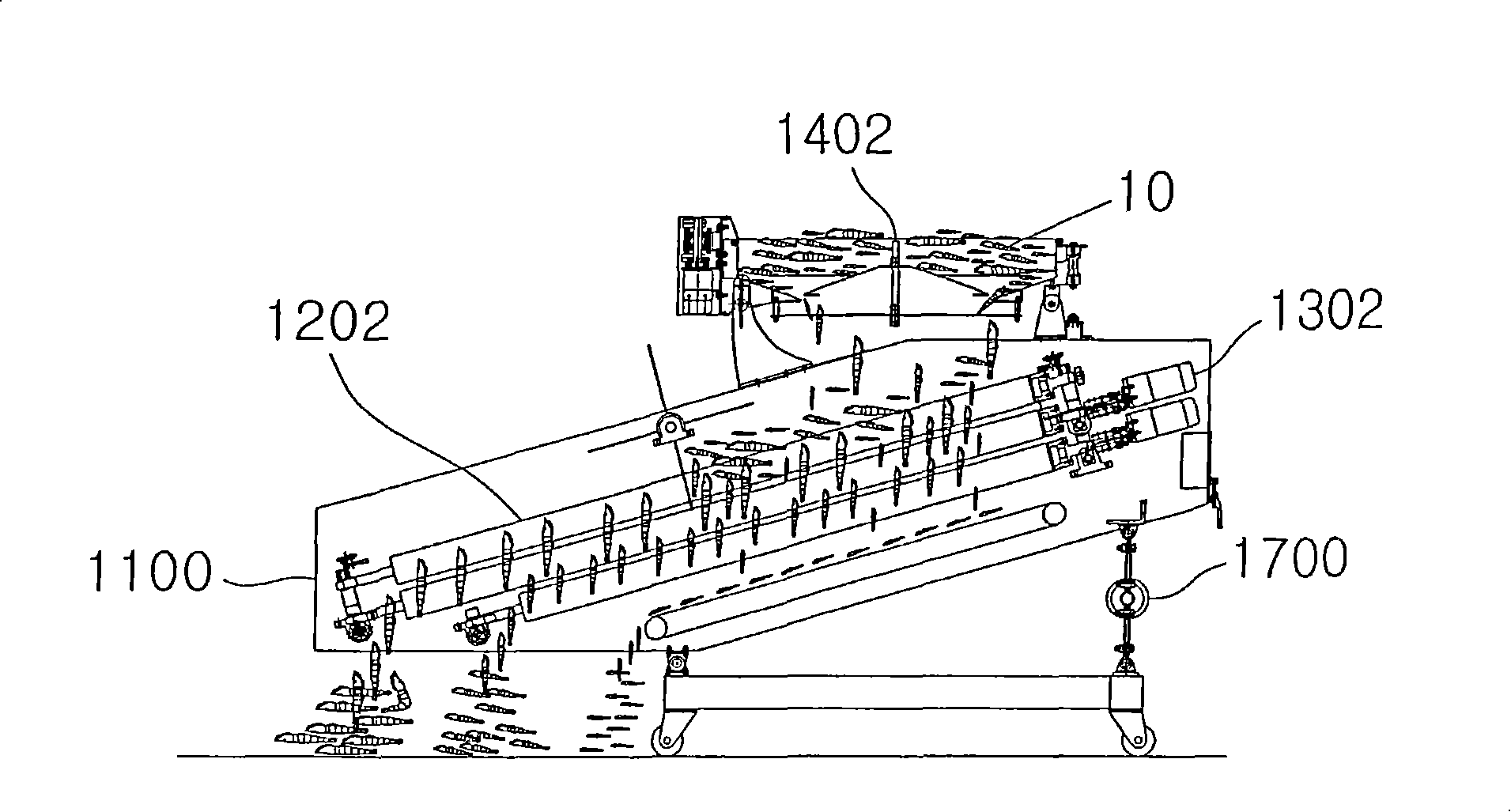

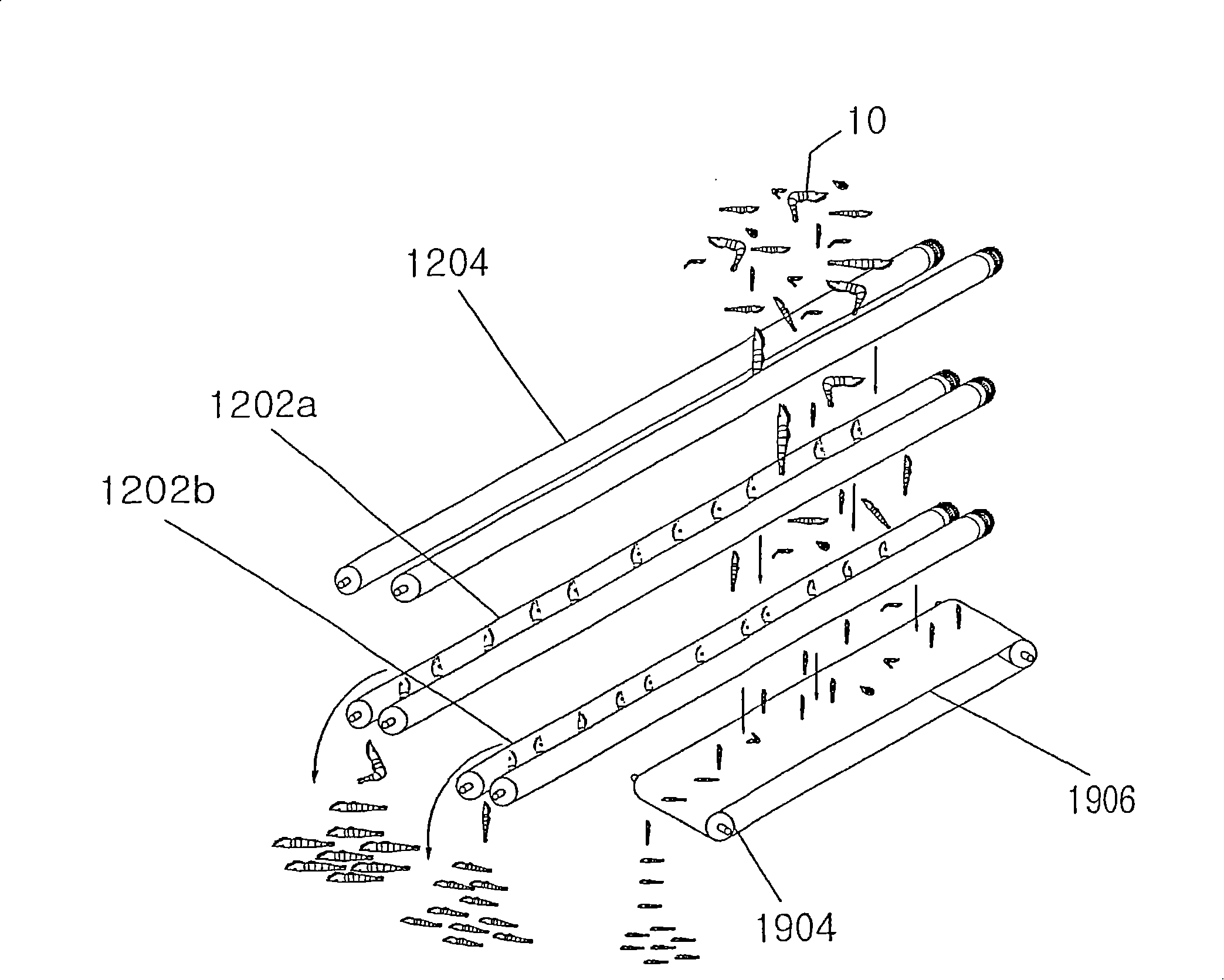

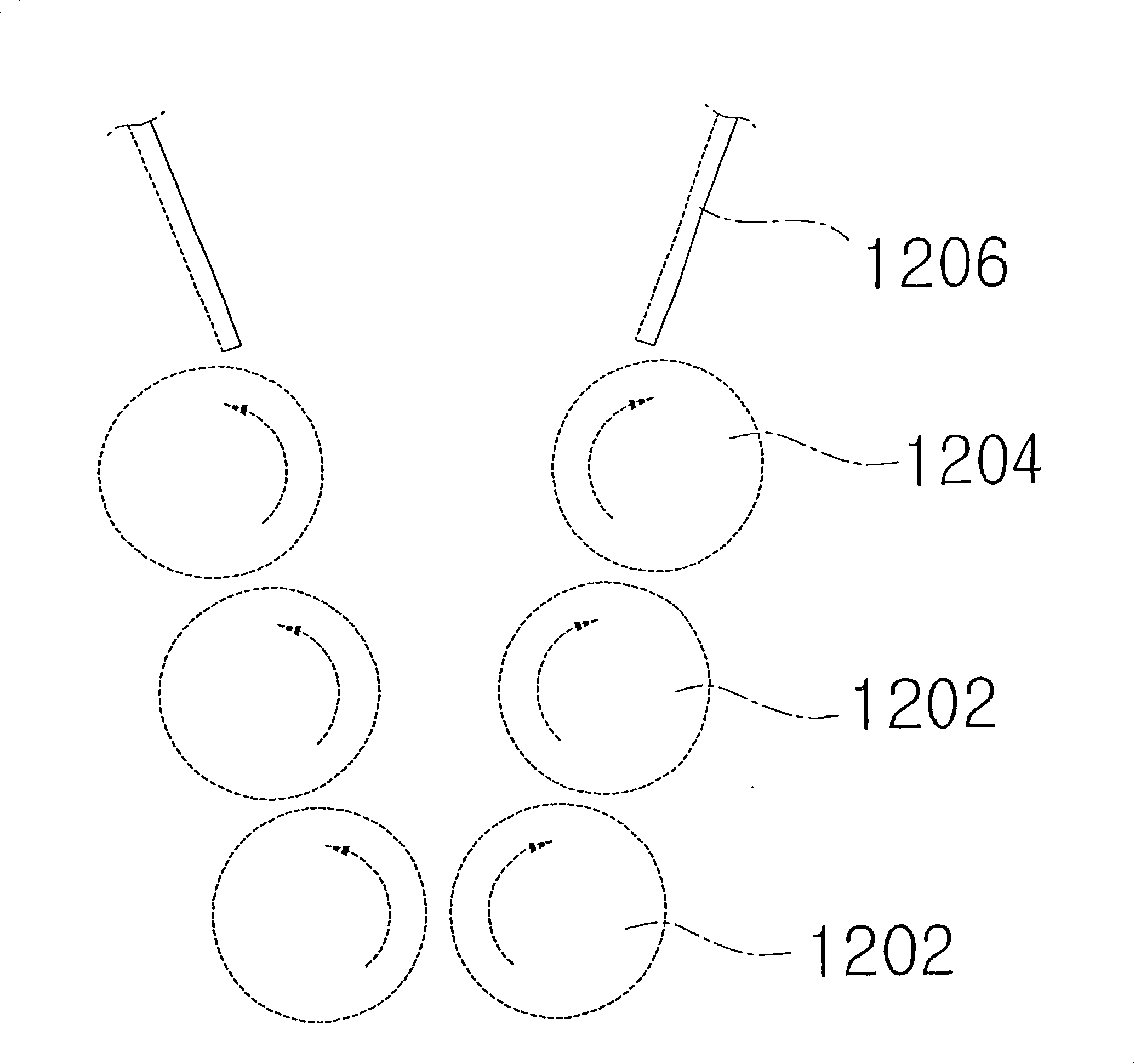

[0047] Fig. 3a is a perspective view showing the structure of the screening unit 110 according to the first embodiment of the present invention, Figure 3b It is a side sectional view showing the arrangement state of the screening unit 110 .

[0048] Figure 3a and Figure 3b As shown, the screening part 110 includes a pair of upper rollers 112a arranged in parallel with each other and one lower roller 112b arranged below the pair of upper rollers 112a.

[0049] Generally, the rotation axes of the three rollers 112a and 112b are all parallel, and the screening part 110 is inclined at a certain angle with respect to the ground. However, in the case of fish such as eels, even if the screening unit 110 is not inclined, it can move by itself and slide down between the rollers 112a and 112b. Therefore, even if the screening unit 110 is arranged parallel to the ground, a predetermined screening effect can be achieved. .

[0050] In addition, the three rollers 112a and 112b are all...

no. 2 example

[0062] FIG. 6a is a perspective view showing the structure of the screening unit 210 according to the second embodiment of the present invention, Figure 6b It is a side sectional view showing the arrangement state of the screening unit 210 .

[0063] In the rollers 212a and 212b used in the second embodiment, the rotation axes of the three rollers 212a and 212b are parallel and inclined at a certain angle with respect to the ground, and all rotate in the same direction.

[0064] However, the three rollers 212a and 212b are not in a cylindrical shape but in a truncated cone shape whose cross-sectional area gradually decreases in the longitudinal direction, which is different from the first embodiment.

[0065] It is desirable that the cross-sectional area of the rollers 212a, 212b decreases with the downward direction of the inclination.

[0066] In this state, when the fish 10 is put between the two upper rollers 212a, after the fish 10 is put through the guide section G a...

no. 3 example

[0071] FIG. 7a is a perspective view showing the structure of the screening unit 310 according to the third embodiment of the present invention, Figure 7b It is a side view which shows the arrangement|positioning state of the filter part 310. FIG.

[0072] Cylindrical rollers 312a and 312b are used in the screening unit 310 according to the third embodiment, and the rotation axis of the upper roller 312a and the rotation axis of the lower roller 312b are opened at a certain angle with respect to the horizontal plane. The central axes of the two upper rollers 312a are arranged in parallel with each other on the same plane, and the central axes of the lower rollers 312b are arranged to be inclined at a predetermined angle with respect to the plane on which the central axes of the two upper rollers 312a are located.

[0073] That is, as Figure 7b As shown, the interval between the upper roller 312a and the lower roller 312b gradually increases toward the discharge port directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com