Manufacturing method of base material for ground cushion and base material for ground cushion

A manufacturing method and technology for substrates, applied in the direction of carpets, etc., can solve the problems of difficulty in manufacturing thin and light products, low tensile strength, difficulty in satisfying durability, slip resistance and excellent texture at the same time, and achieve sufficient durability and slip resistance. The effect of stability and sufficient tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

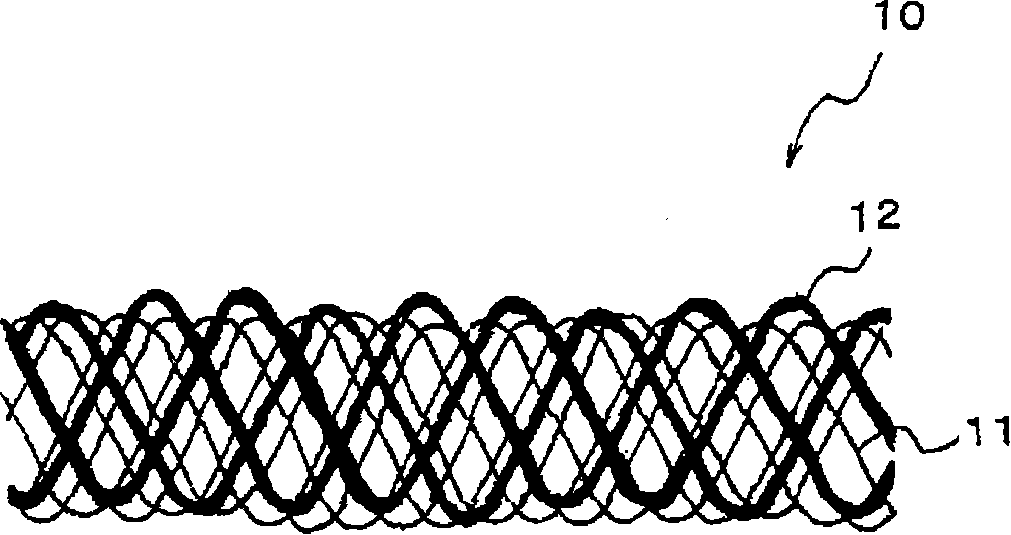

Embodiment 1

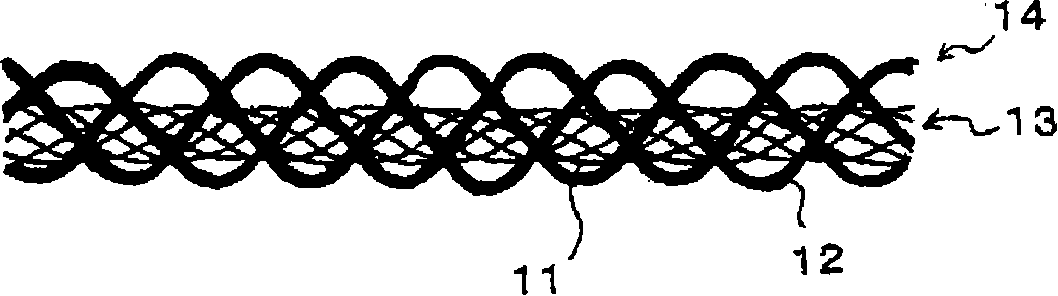

[0047] Polyester fiber (coarse fiber) with a fineness of 90 dtex and a fiber length of 76 mm and a polyester fiber (fine fiber) with a fineness of 6.6 dtex and a fiber length of 51 mm were used by blending them at a ratio of 50%:50%. form a fiber web.

[0048] Next, use knitting needles with a barb depth (0.12mm) corresponding to the fineness of the fine fibers 6.6dtex (100 / cm from above) 2 , 60 pieces / cm from below 2 ) to implement complexation treatment.

[0049] Then, through the above-mentioned complexation treatment, such as figure 2 As shown, a high-density fiber layer mainly composed of thin fibers is formed at the center, and a low-density fiber layer mainly composed of thick fibers is formed on the surface of the high-density fiber layer.

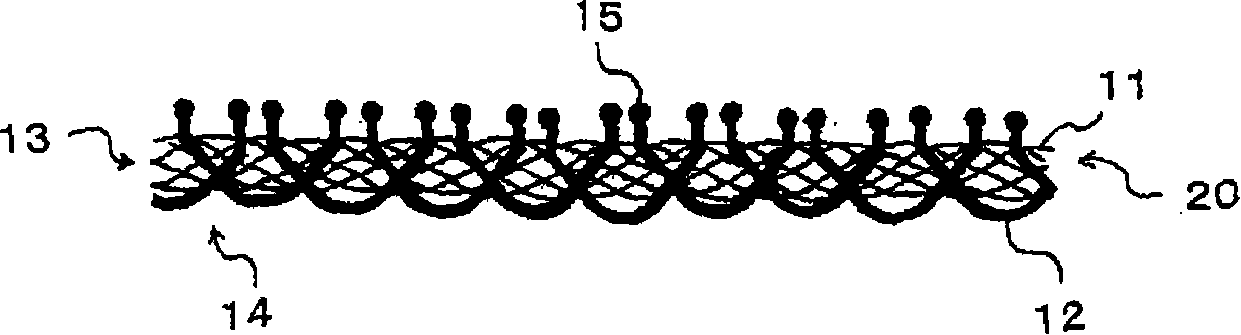

[0050] Afterwards, the low-density fiber layer is heat-treated. From above the low-density fiber layer, the fibers constituting the low-density fiber layer are singed with a gas heater to perform heat treatment. By this heat ...

Embodiment 2

[0052] A base material was produced in the same manner as in Example 1, except that the blending ratio of the thick fiber and the thin fiber was set at a ratio of 20% of the thick fiber and 80% of the thin fiber.

Embodiment 3

[0054] Use a polyester fiber (thick fiber) with a fineness of 44 dtex and a fiber length of 76 mm and a polyester fiber (fine fiber) with a fineness of 6.6 dtex and a fiber length of 51 mm, which are set as thick fibers A base material was produced in the same manner as in Example 1 except that the ratio of 20% and 80% of thin fibers was used. The diameter of the resin block at the tip of the fiber fused by the heat treatment is 0.10 to 0.24 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com