Aluminum alloy for compressor sliding member, compressor sliding member forging, and manufacturing method thereof

A technology of sliding parts and compressors, which is applied in the field of aluminum alloy, can solve the problems of uneven thickness of aluminum oxide film, decrease of hardness of aluminum oxide film, hindering the growth of aluminum oxide film, etc., and achieve excellent film strength, sufficient tensile strength, excellent Effect of Aluminum Oxide Film Treatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

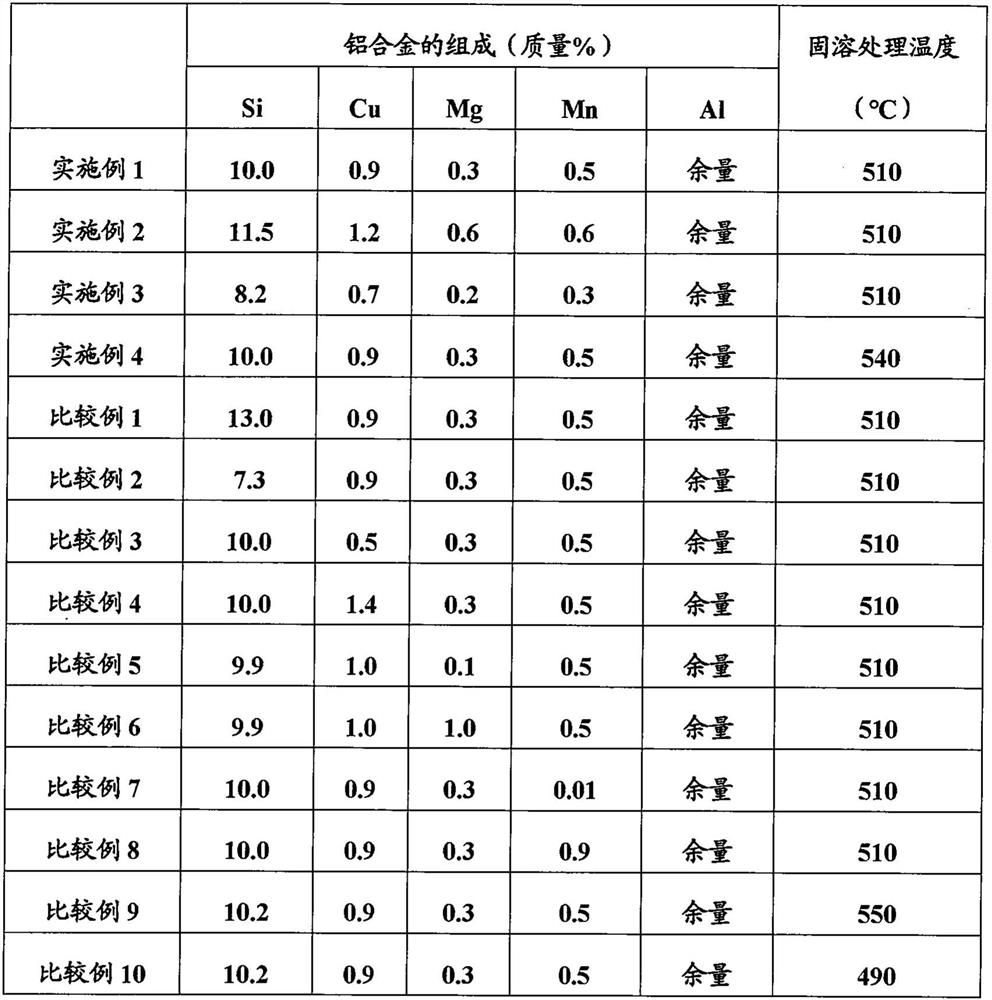

[0081] By continuously casting an aluminum alloy melt containing Si: 10.0 mass %, Cu: 0.9 mass %, Mg: 0.3 mass %, Mn: 0.5 mass %, and the balance consisting of Al and unavoidable impurities, obtained Cast material (cast material) with a diameter of 82 mm. The cooling rate at the time of casting was 15 degreeC / sec. After the homogenization heat treatment in which the obtained cast material was heated under the conditions of 470° C.×7 hours, it was air-cooled.

[0082] After cutting the above-mentioned cast material into a length of 30 mm, forging was performed at a material temperature of 420°C and a die temperature of 180°C. In the forging, 80% upsetting was performed in the direction parallel to the axial direction of the cast material, assuming the bottom of the scroll forged product, to obtain a forged material.

[0083] The forged material was heated at 510°C for 3 hours to perform solution treatment, and then water quenched with water at 25°C. Next, artificial aging tr...

Embodiment 2

[0085] A forged product was obtained in the same manner as in Example 1, except that the aluminum alloy melt having the alloy composition (containing inevitable impurities) shown in Table 1 was used.

Embodiment 4

[0087] A forged product was obtained in the same manner as in Example 1, except that the aluminum alloy melt having the alloy composition (containing unavoidable impurities) shown in Table 1 was used, and the solution treatment temperature was set to 540°C. .

[0088]

[0089] A forged product was obtained in the same manner as in Example 1, except that the aluminum alloy melt having the alloy composition (containing inevitable impurities) shown in Table 1 was used.

[0090]

[0091] A forged product was obtained in the same manner as in Example 1, except that the aluminum alloy melt having the alloy composition (containing unavoidable impurities) shown in Table 1 was used, and the solution treatment temperature was set to 550°C. .

[0092]

[0093] A forged product was obtained in the same manner as in Example 1, except that the aluminum alloy melt having the alloy composition (containing unavoidable impurities) shown in Table 1 was used, and the solution treatment tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com