Reinforced composite board based on concrete bending member

A technology of composite panels and bending components, which is applied in building construction, building maintenance, construction, etc., and can solve problems such as fiber material peeling and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings.

[0020] The first step is to apply prestress to the fiber material, anchor the two ends of the fiber material to the tensioning device, perform tension and ensure that the surface of the fiber material is straight, and stop the tension after reaching the prestress control value and maintain the prestress.

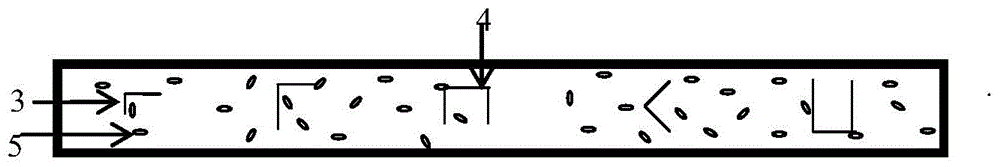

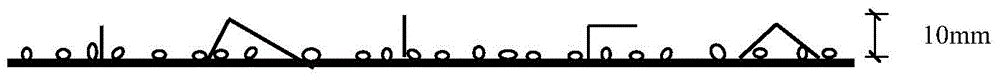

[0021] After the second step of stretching, a PVC template with high smoothness is placed on the lower part of the fiber material, and then the fiber is brushed and reinforced with organic glue, and a certain amount of special-shaped steel fiber and mung bean sand are pasted before the glue is initially set.

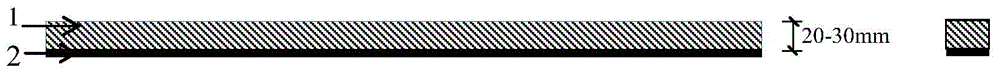

[0022] In the third step, after the final setting of the structural glue, smear high-strength mortar with a thickness of 20mm-30mm on the mung bean sand and carry out maintenance.

[0023] The fourth step is to wait unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com