Device and method for leveling metal strips

一种金属带材、带材的技术,应用在进给装置、金属轧制、定位装置等方向,能够解决很少能实现平面等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

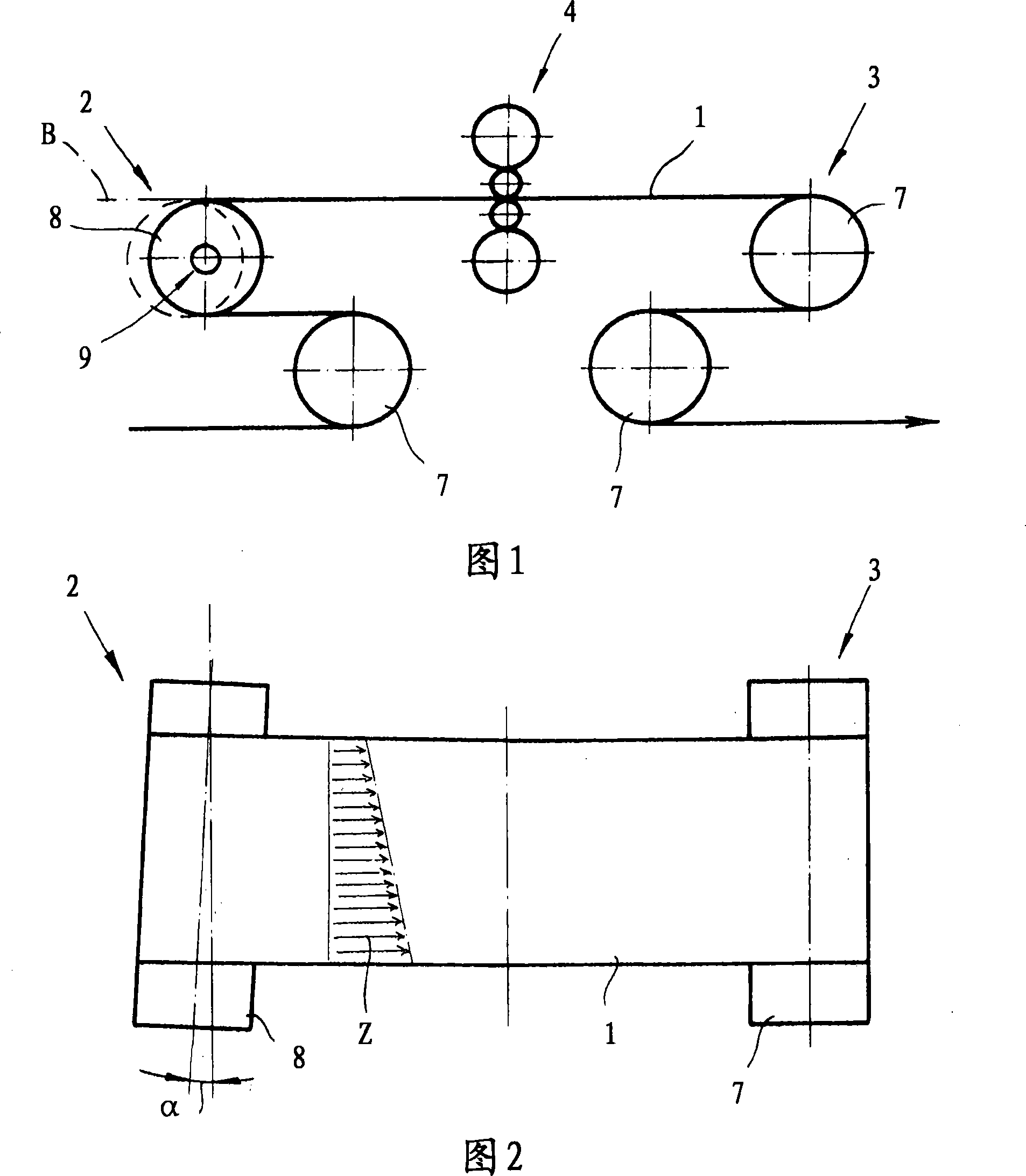

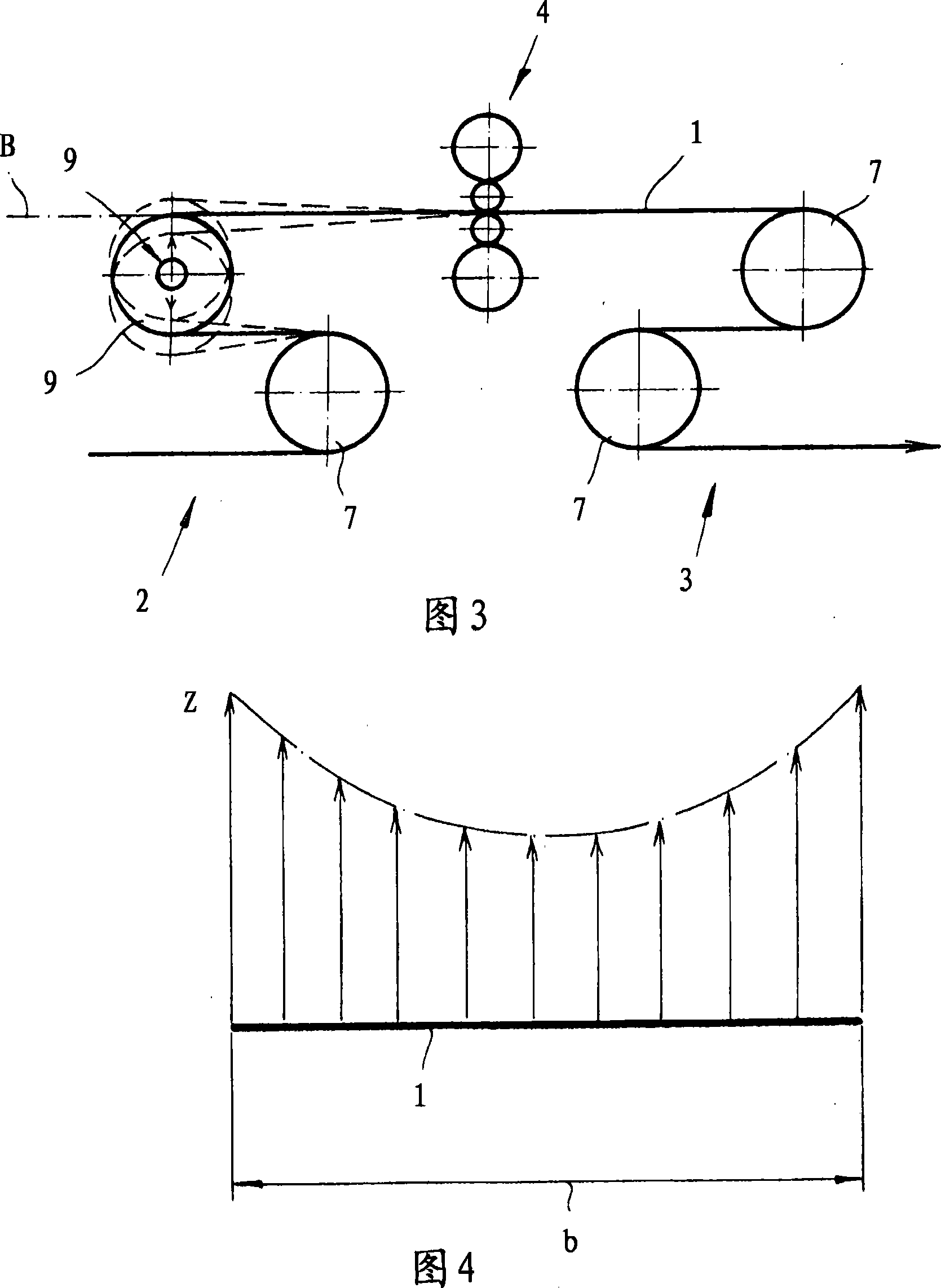

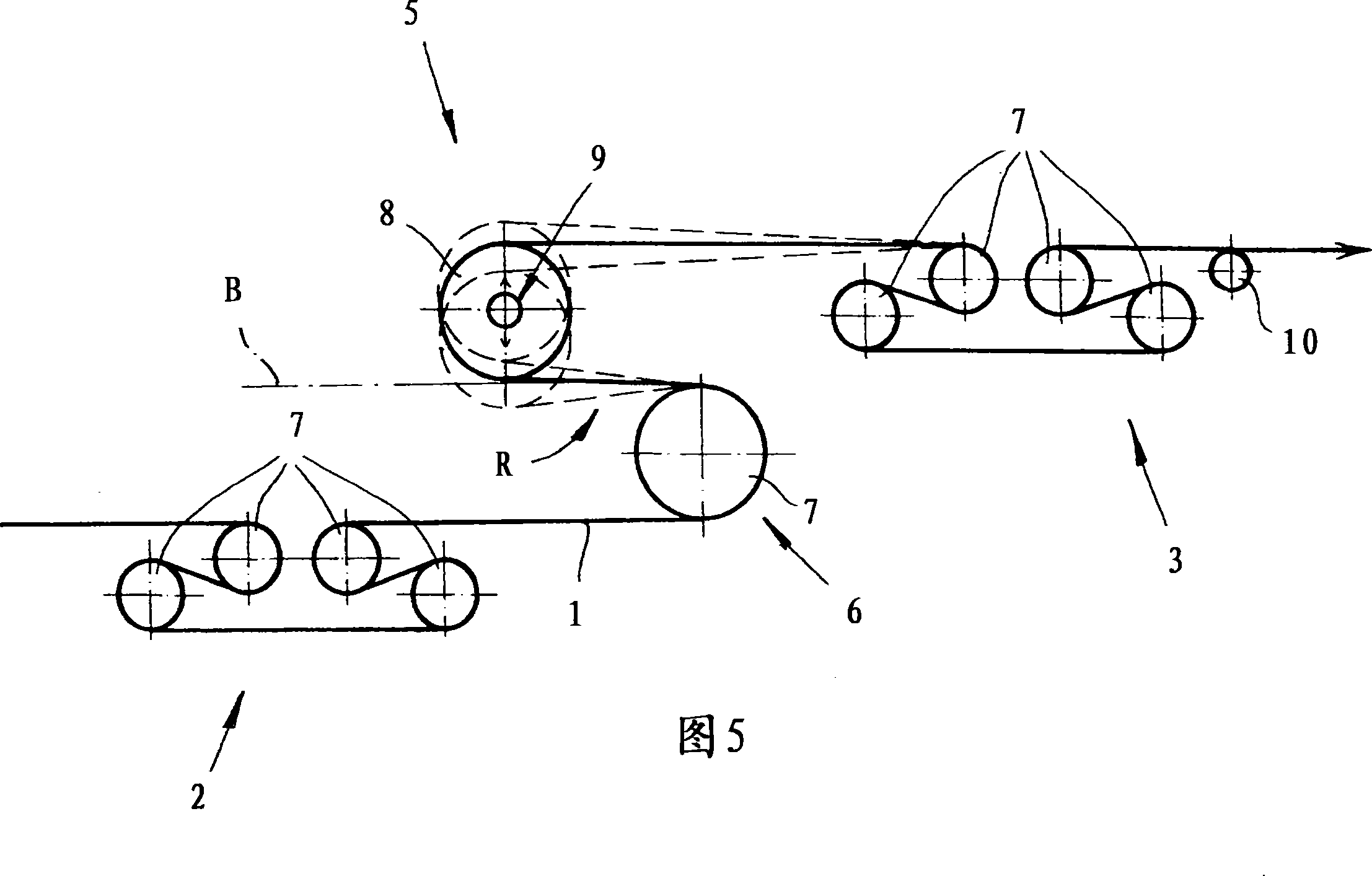

[0020] The figures show different embodiments of a device for smoothing a metal strip 1 , in particular a thin metal strip made of an aluminum alloy. This device has at least one tensioning roller set 2 configured as an inlet tensioning roller set and at least one tensioning roller set 3 configured as an exit tensioning roller set, wherein the inlet tensioning roller set 2 serves to build up the tension and the exit tensioning roller set 3 Tight roll group 3 is used for removing tension. Between the inlet tension roll set 2 and the exit tension roll set 3 , a strip processing device, for example a rolling stand 4 ( FIGS. 1 to 4 ) and / or a stretching unit 5 ( FIG. 5 ) can be arranged. The stretching unit 5 of FIG. 5 has a further set of tensioning rollers 6 configured as a set of stretching rollers.

[0021] According to the invention it is now provided that at least one tensioning roller 7 , 8 of at least one tensioning roller set 2 , 3 , 6 is pivotable in and / or transversely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com