Foot rest for supporting tool machine

A technology of machine tools and feet, which is applied in the direction of manufacturing tools, workbenches, pivot connections, etc., can solve the problems of increasing storage space and easily tripping other objects, and achieves the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

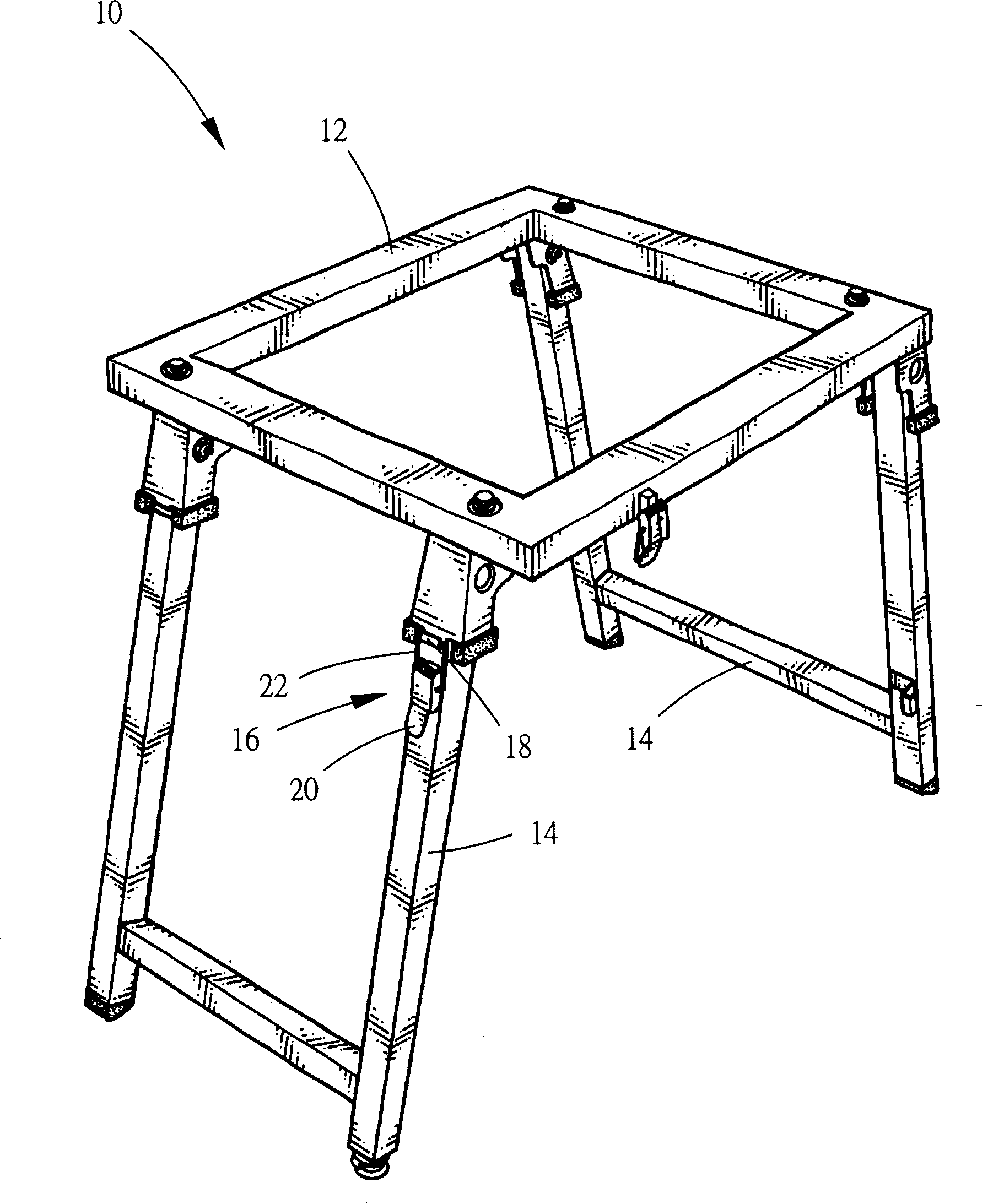

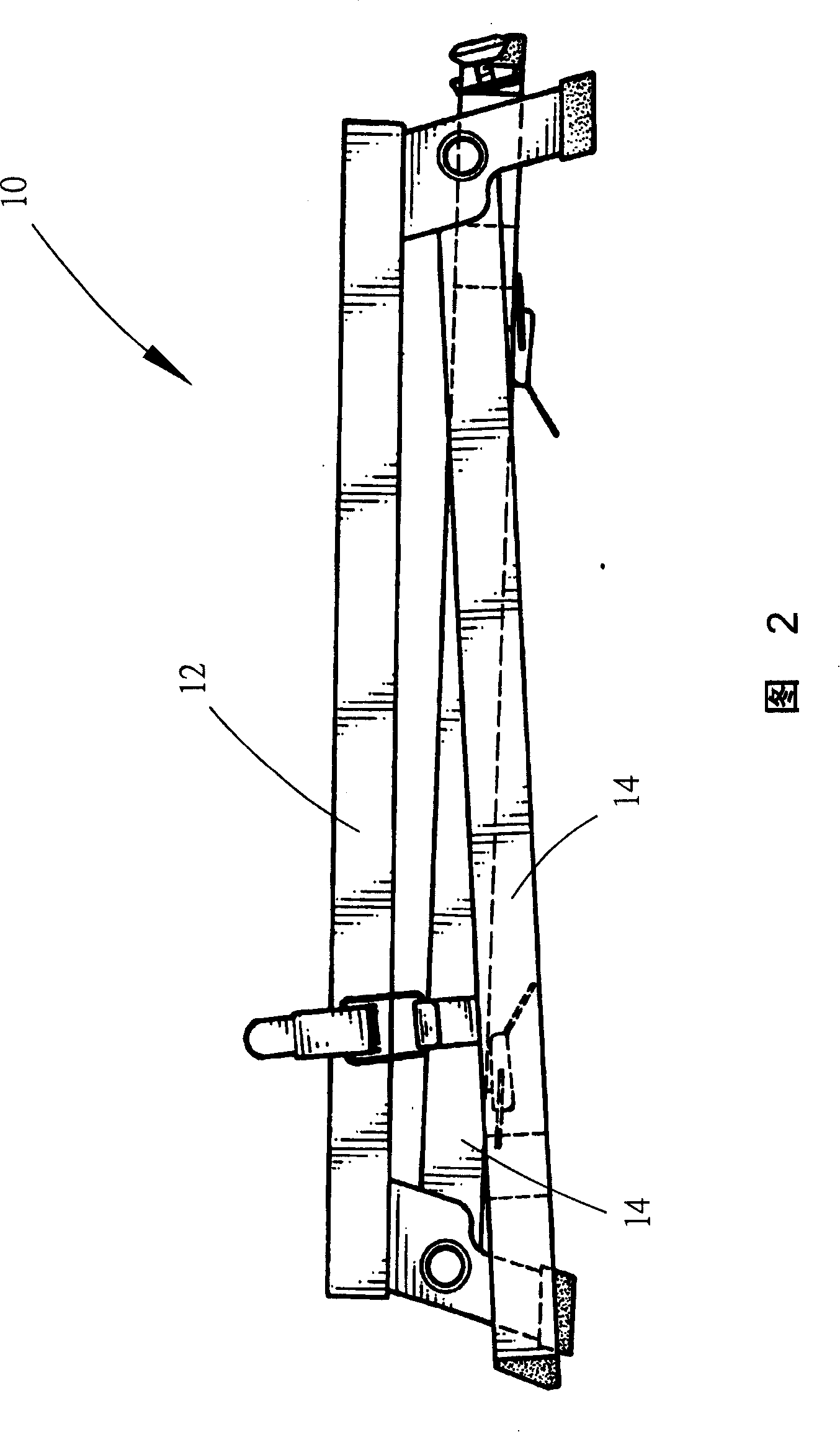

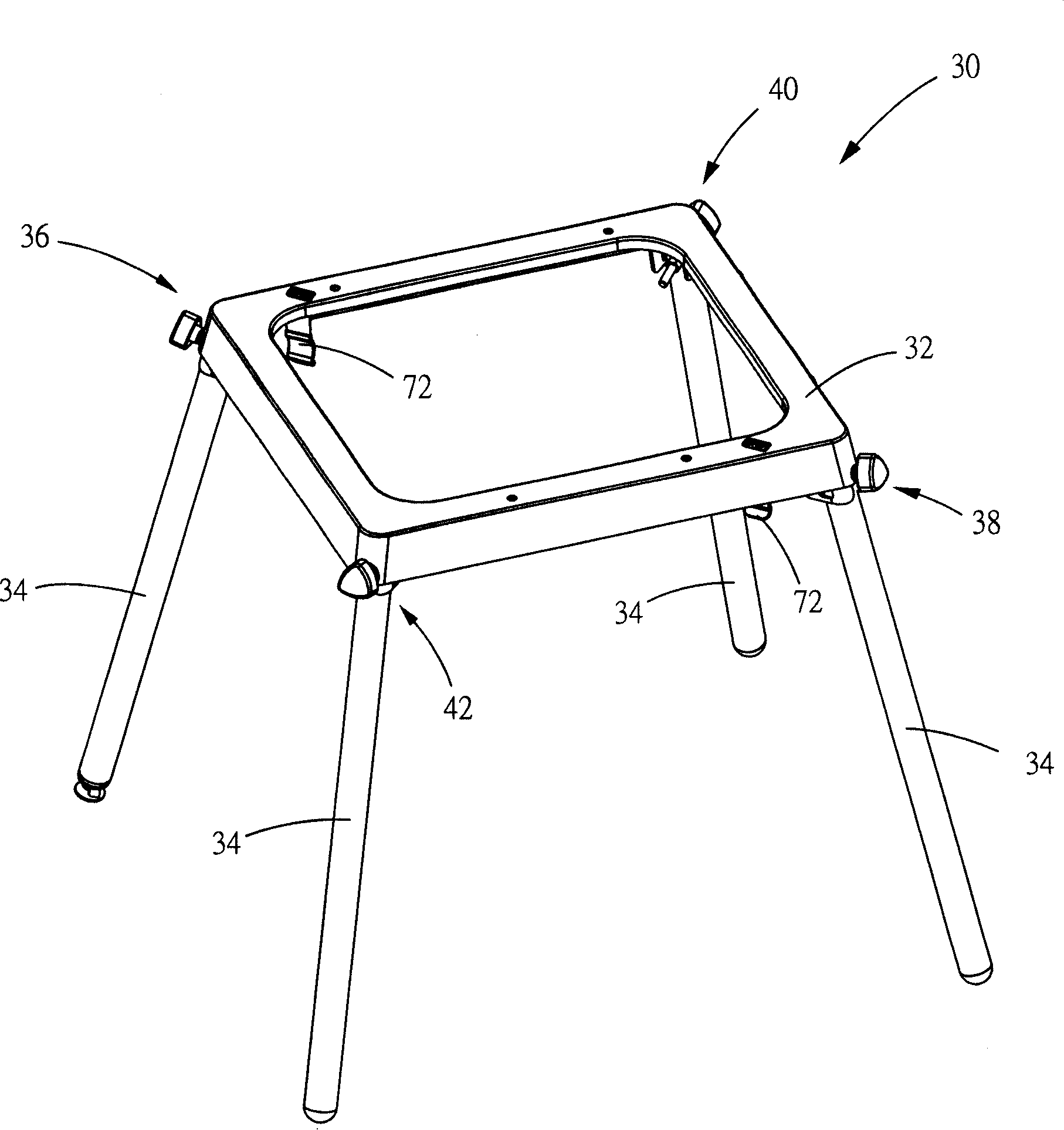

[0016] see image 3 and Figure 4 , image 3 It is a top perspective view of the tripod 30 in an unfolded state according to an embodiment of the present invention. The present invention is a tripod 30 for supporting a machine tool, the machine tool can be a table saw machine, a miter saw machine, a wire saw machine, a band saw machine, a drilling machine, a sanding machine, a planer, a cutting machine Etc., the stand 30 includes a platform 32, four legs 34 and a connecting component. The platform 32 is used to carry the tool machine above it, and the platform 32 can be in various shapes, such as a circular flat plate, a rectangular flat plate, a rectangular frame... In this embodiment, the rectangular frame is used as the example for illustration. The four legs 34 are respectively arranged at the four corners of the platform 32 and are located below the platform 32 in the shape of a round rod. When in the unfolded state, the four legs 34 stand on the ground to prop up the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com