Injection mold assembly

A technology of injection molding and metal molds, applied in the field of metal molds, can solve the problems of reduced heating and cooling efficiency, poor demoulding, and reduced forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

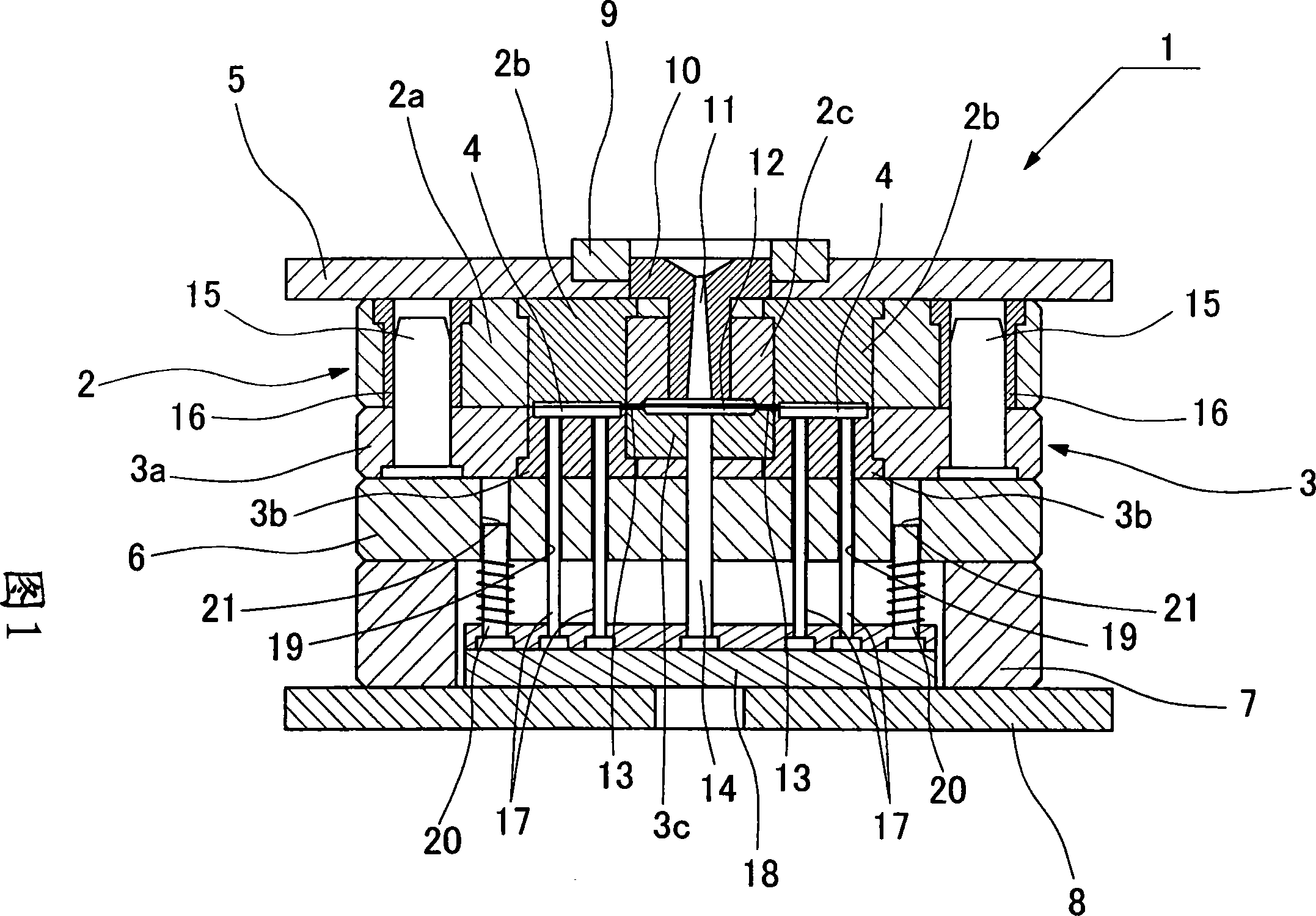

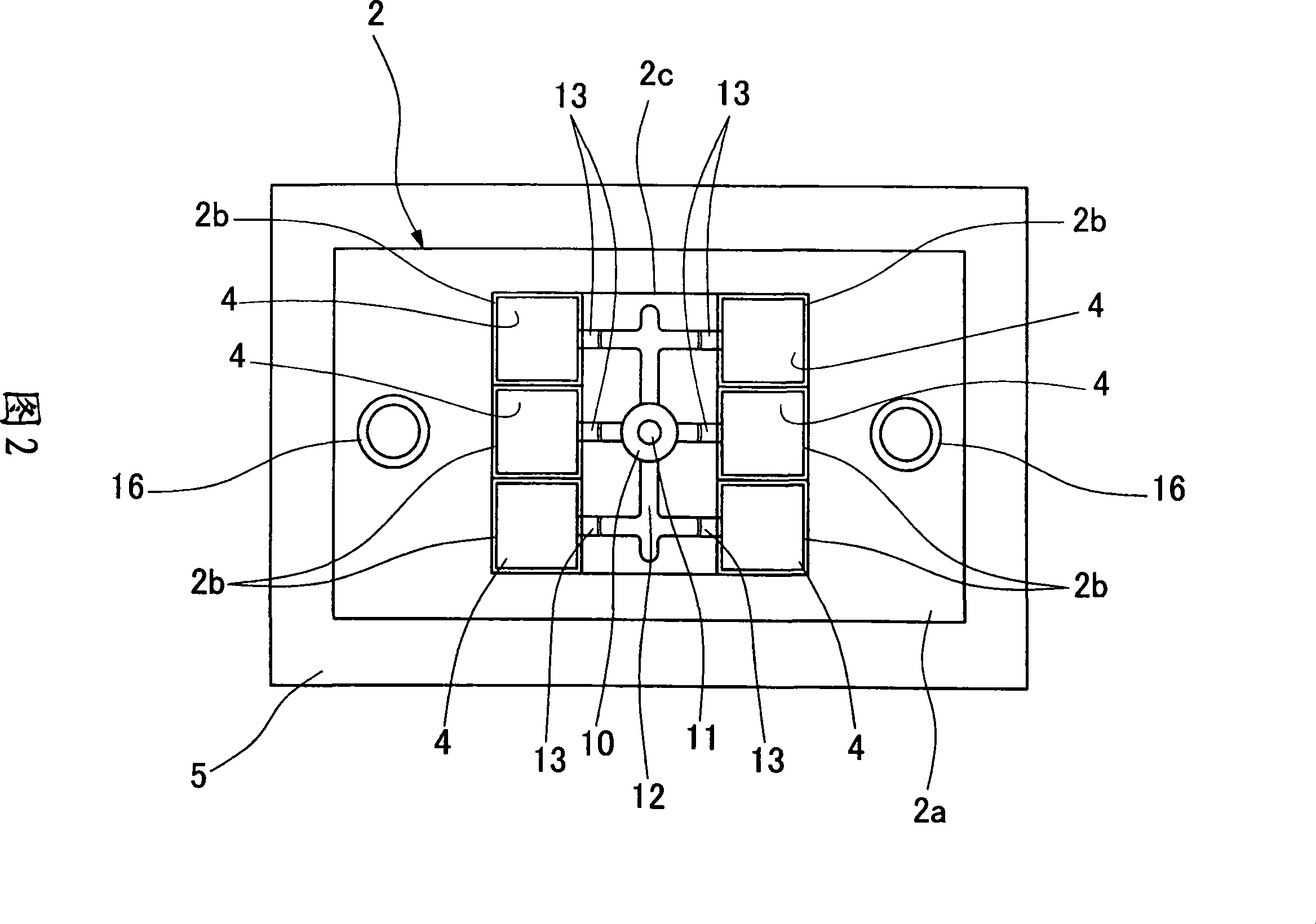

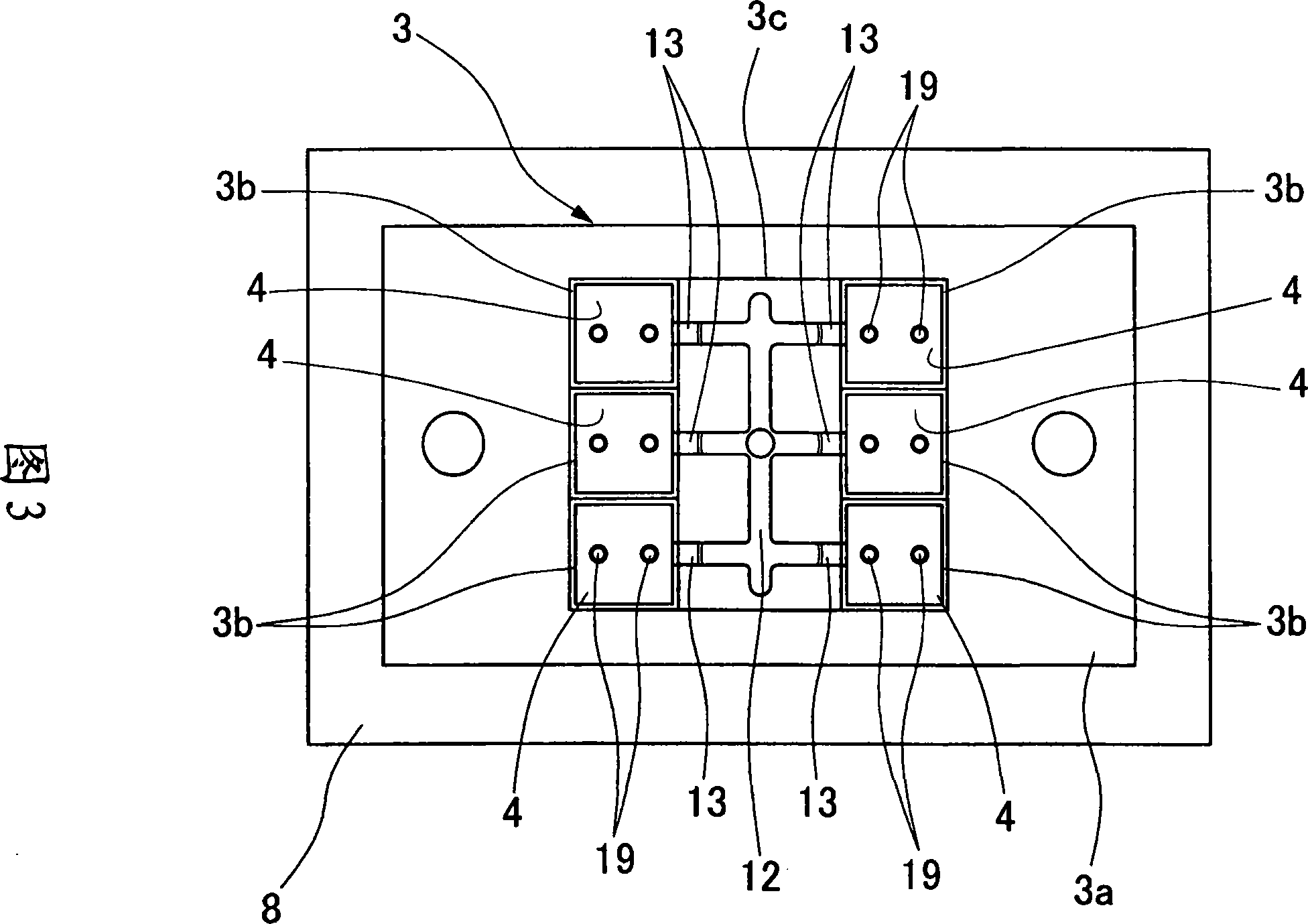

[0024] Embodiments of the present invention will be described below with reference to the drawings. Fig. 1 is a longitudinal sectional view showing a metal mold for injection molding. As can be seen from this figure, the molding die 1 has a fixed mold member 2 shown in FIG. 2 and a movable mold member 3 shown in FIG. , forming a cavity 4 therebetween. Here, both the fixed mold member 2 and the movable mold member 3 are formed by attaching cores 2b, 3b to die plates 2a, 3a, and a cavity 4 is formed between the cores 2b, 3b. In addition, although the fixed mold member 2 and the movable mold member 3 are constituted by members respectively different from the core and the die plate, they may be constituted by an integral member.

[0025] The fixed mold part 2 is fixed on the fixed-side mounting plate 5 , and the movable mold part 3 is connected to the movable-side mounting plate 8 via the support plate 6 and the spacer 7 . A positioning ring 9 is installed on the fixed-side mou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com