Concealed roller hydraulic replacement three-fold sliding track

A hidden, roller technology, used in furniture parts, home utensils, drawers, etc., can solve problems such as objects moving smoothly, large sliding friction, and large friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

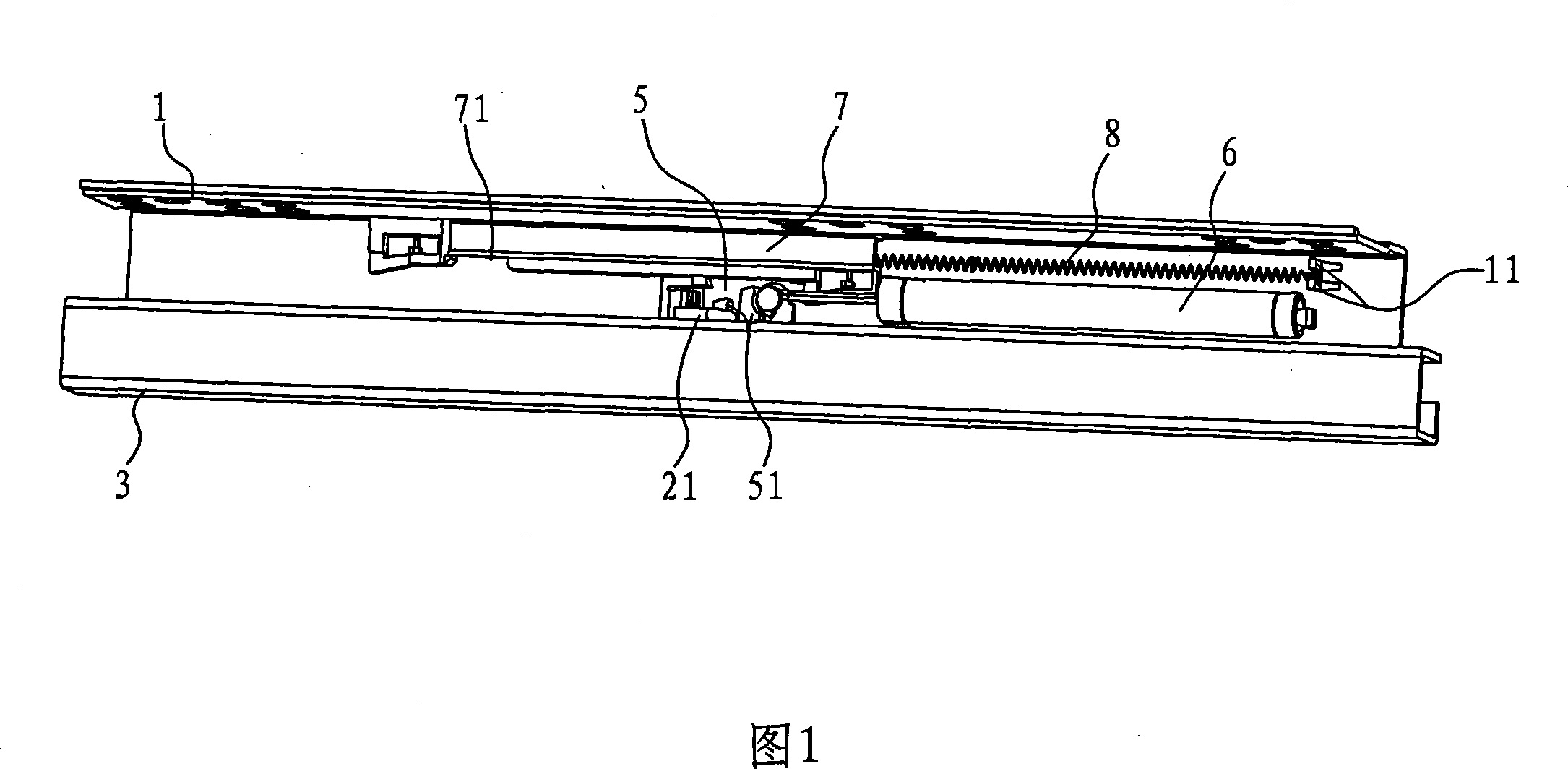

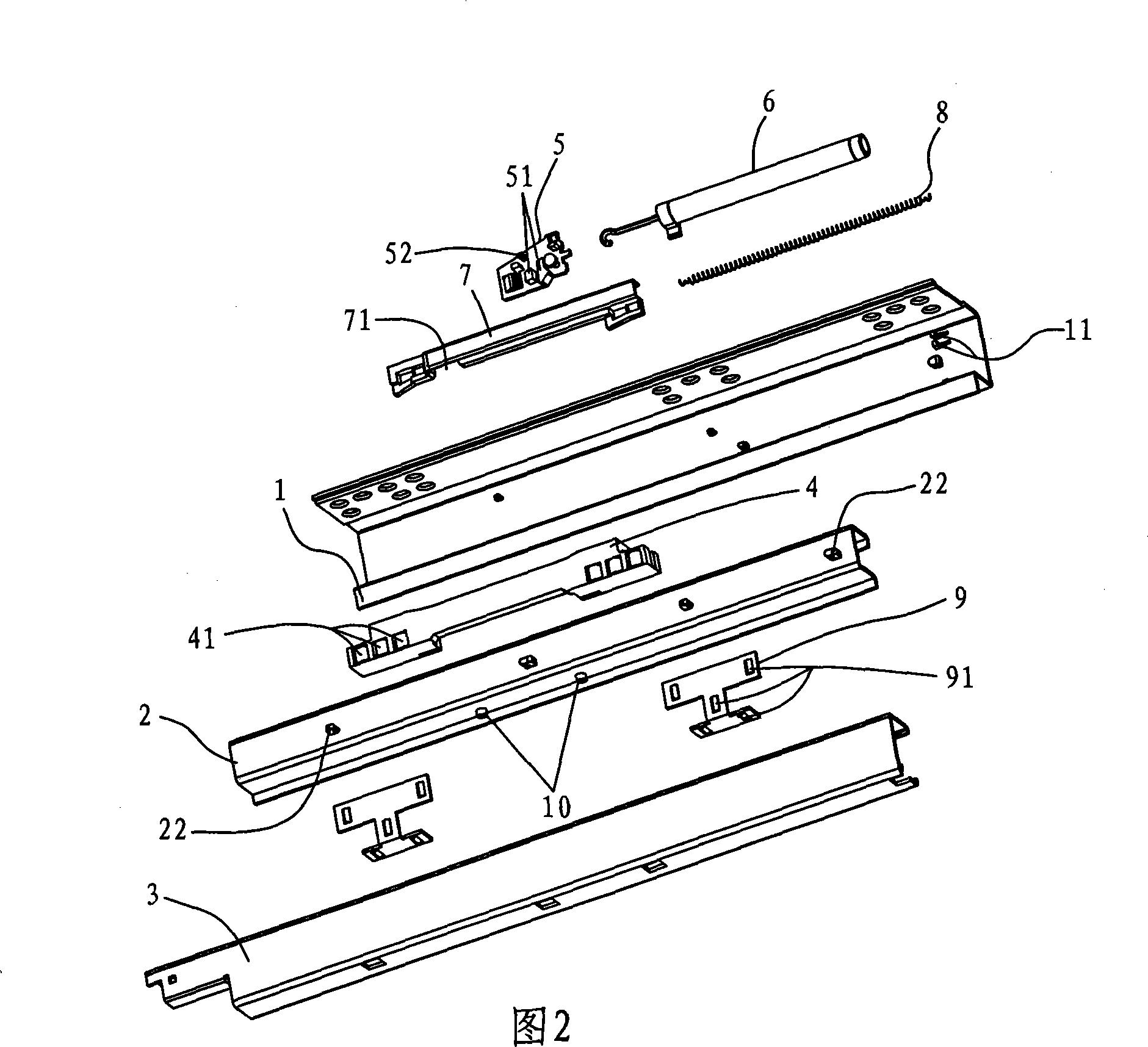

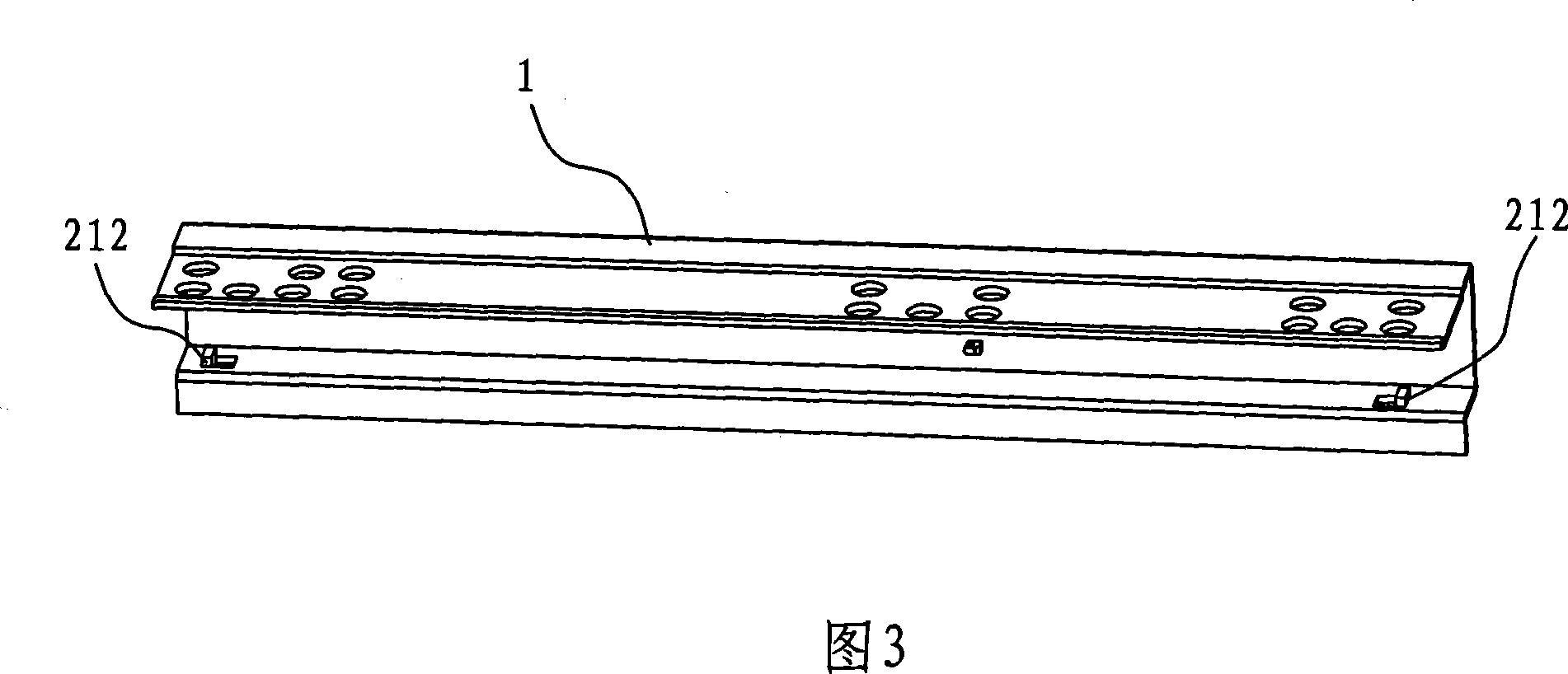

[0018] As shown in Figures 1 to 4, the present invention includes an outer rail 1, a middle rail 2 and an inner rail 3, one side of the outer rail 1 and the middle rail 2 are nested and connected by a roller bracket 4, and the inner rail 3 is slid by a roller The block 9 is nested on the middle rail 2, and the roller slider 9 is clamped on the middle rail 2, and the middle rail 2 is provided with a block 22 to prevent the roller slider 5 from slipping off, and also includes a reset slider 5. Hydraulic damping piston 6, fixed cover plate 7 and tension spring 8; the fixed cover plate 7 is fixed on the inner groove surface of the outer rail 1, and one side of the reset slider 5 is slid on the middle rail 2 and the outer rail 1 to form a The other side slides in the fixed cover plate 7; one end of the inner side of the middle rail 2 is provided with a dial 21 to toggle the reset slider 5, and the reset slider 5 is provided with two clip dials. 21, one end of the reset slider 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com