Extrusion jolt moulded concrete segment palletizing method

A concrete block and vibration forming technology, which is applied in the stacking of objects, unloading devices, manufacturing tools, etc., can solve the problems of waste, affecting the transfer, and falling blocks, so as to avoid waste and ensure smooth progress. The effect of maintaining integrity

Inactive Publication Date: 2008-08-20

王海清

View PDF1 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in actual operation, it is found that although two adjacent layers of blocks are staggered by 90 degrees for stacking, when the forklift forks up the backing plate at the bottom of the brick stack, the whole stack of bricks (blocks) is lifted for transfer. In the process, due to the vibration of the forklift truck, some blocks will often fall from the brick stack, which will affect the transfer and cause waste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

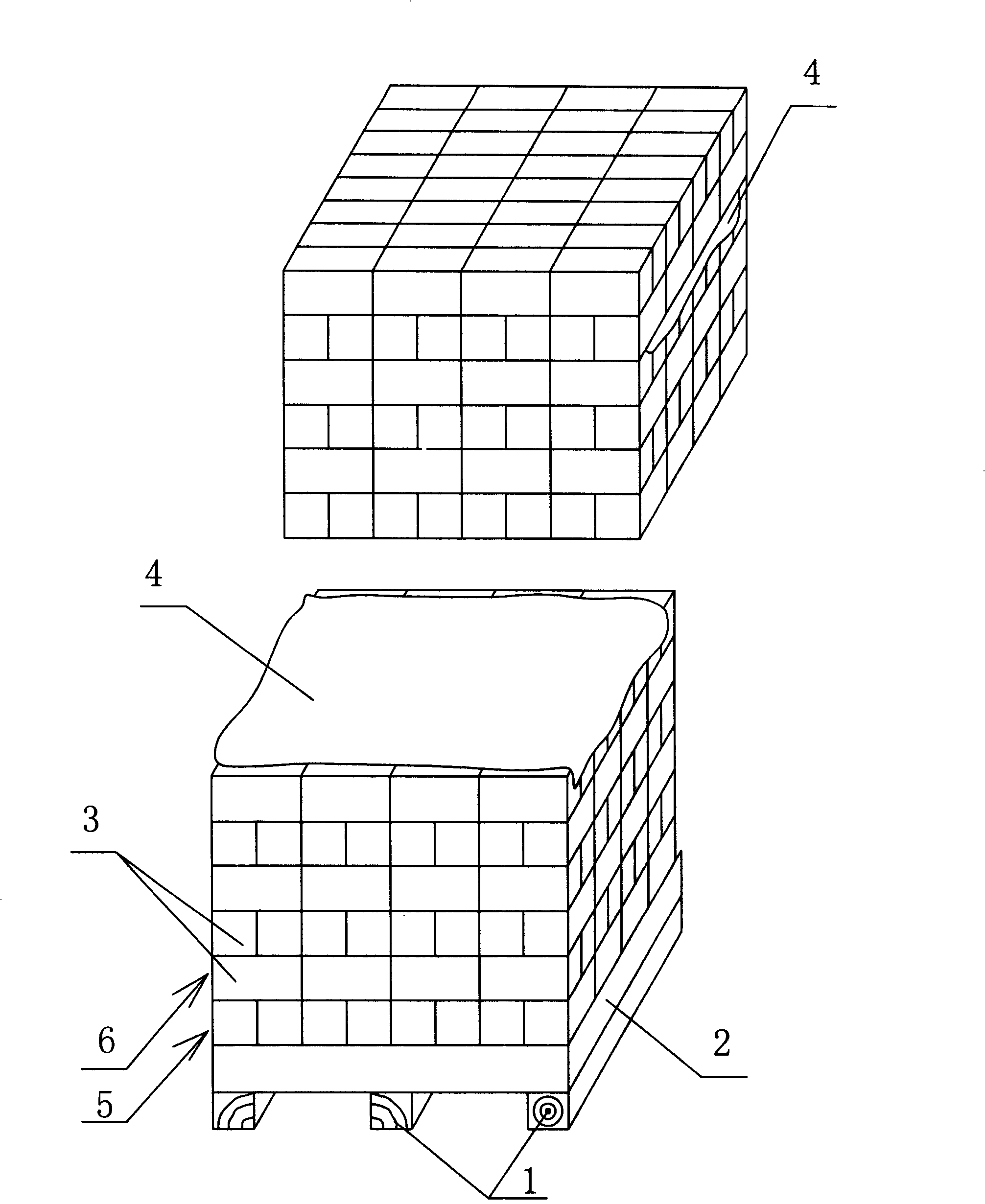

[0016] Example: Concrete blocks formed by extrusion vibration. The size of a single block is 240mm×115mm×90mm. It is a hollow block. Sixth, eighth, and tenth layers of top surfaces are respectively placed as the fiber cloth of the pinning layer 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a concrete brickwork palletizing method for extruding vibration forming, which is characterized in that a plurality of forming brickworks are overlapped layer by layer on a bottom plate (2), and the adjacent two forming brickworks are relatively staggered for ninety degrees; a pinning layer is arranged on the top surface of at least one layer of forming brickworks during the palletizing process layer by layer for the forming brickworks, and then the higher layer of forming brickworks are arranged on the pinning layer until finishing the palletizing. The concrete brickwork palletizing method has the advantages that the phenomena for stack-break or the brickworks falling off from the stack are avoided during the transportation of the brickwork stack; the completeness of the brickwork stack during the transportation is reliably maintained, thus the waste is avoided, and the smooth transportation for the product can be ensured.

Description

technical field [0001] The invention relates to a production method of building materials, in particular to a stacking method of concrete blocks formed by extrusion and vibration. Background technique [0002] In the traditional production method of concrete blocks, the strength of the blocks after forming is limited, and they must be placed on the shelf in a single layer for hardening, and then stacked; this not only takes up a lot of space, but also makes the production process cumbersome and consumes The cost in transshipment is high and the production efficiency is low. The inventor of this patent application has developed the process and equipment for forming concrete blocks by extrusion vibration (another patent has been applied for), which solves the strength problem of the formed blocks, and can directly stack the formed concrete blocks for hardening, greatly improving The production site and cost are saved. However, in actual operation, it is found that although t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B28B13/04B65G57/20

Inventor 王海清王谢辉

Owner 王海清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com