Floor block with active carbon

A technology of activated carbon and floor boards, applied to floors, disinfection, and insulation layers, etc., can solve the problem of not having the ability to remove harmful substances in the room, and achieve the effects of long-lasting filtration and removal, improved air quality, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

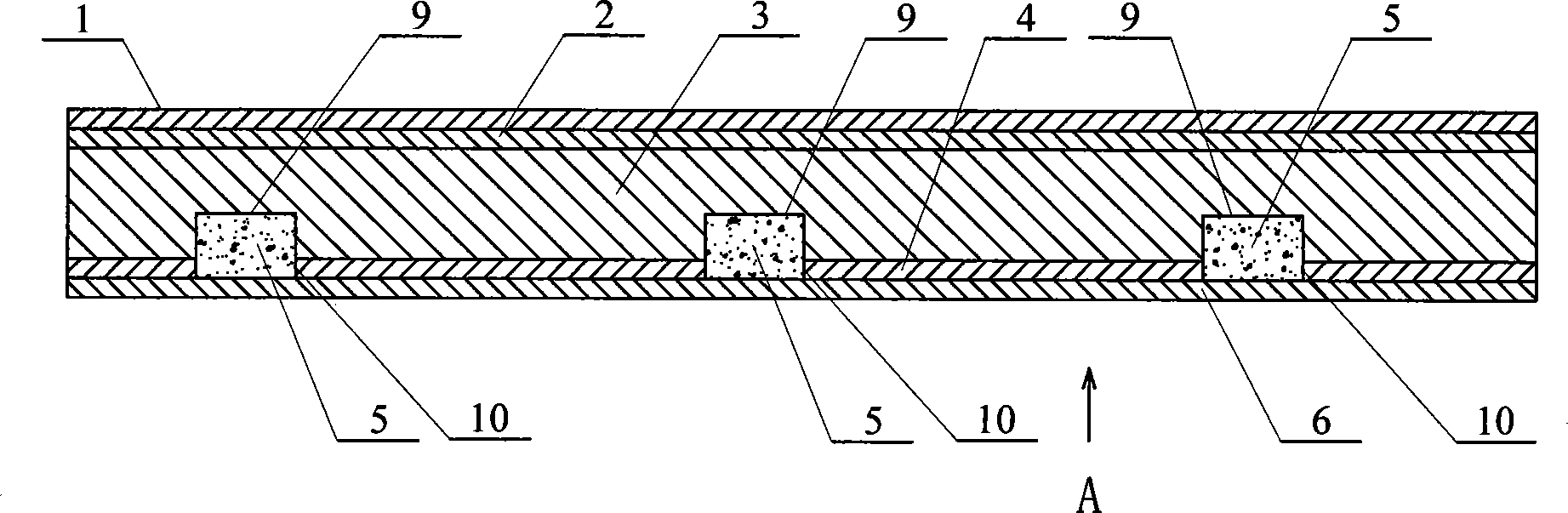

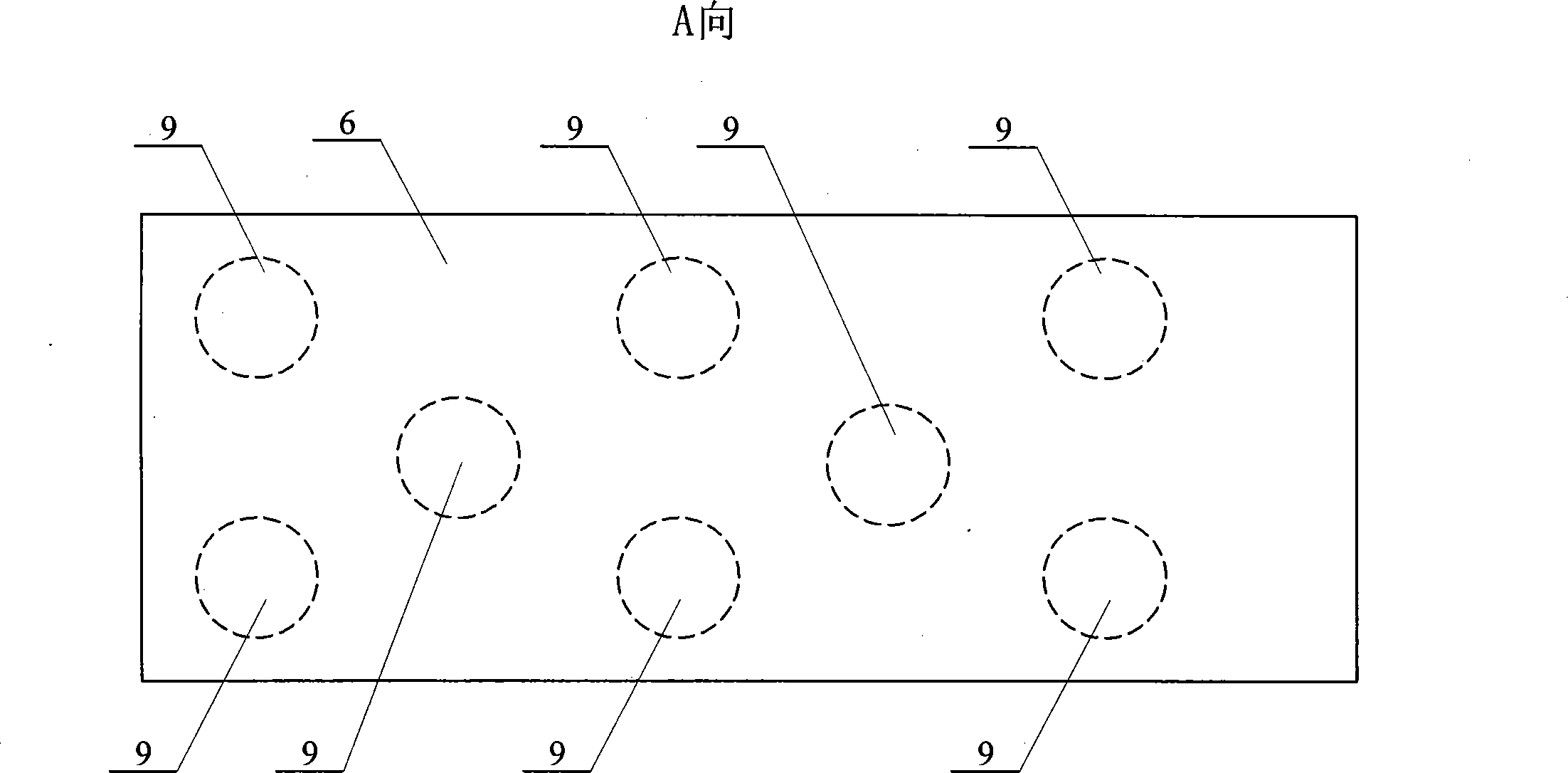

[0006] Specific implementation mode one: (see Figure 1 ~ Figure 2 ) This embodiment consists of a wear-resistant layer 1, a decorative layer 2, a substrate layer 3, a balance layer 4, activated carbon 5, and a breathable interlayer 6. The bottom surface of the wear-resistant layer 1 is fixedly connected to the top surface of the decorative layer 2, and the decorative layer The bottom surface of the base material layer 3 is fixedly connected with the top surface of the base material layer 3, the bottom surface of the base material layer 3 is provided with a groove 9, the top surface of the balance layer 4 is fixedly connected with the bottom surface of the base material layer 3, and the balance layer 4 is provided with a The through hole 10 corresponding to the groove 9 on the bottom surface of the material layer 3, the activated carbon 5 is fixed in the groove 9 on the bottom surface of the base material layer 3 and the through hole 10 of the balance layer 4, the top surface o...

specific Embodiment approach 2

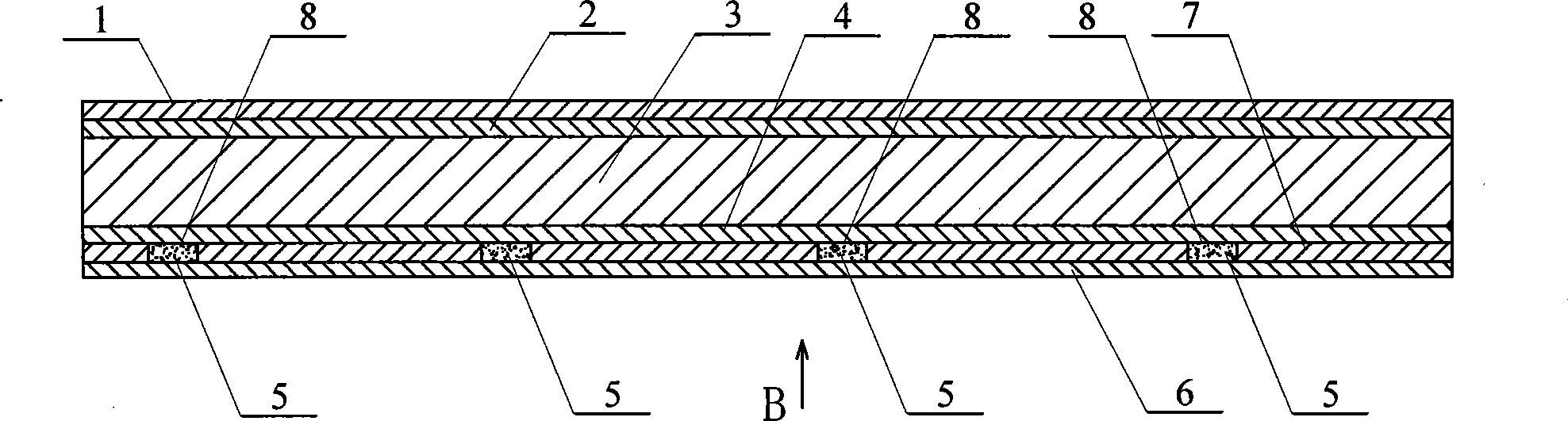

[0007] Specific implementation mode two: (see Figure 3 ~ Figure 4 ) This embodiment consists of a wear-resistant layer 1, a decorative layer 2, a base material layer 3, a balance layer 4, activated carbon 5, a breathable interlayer 6 and a quiet layer 7, and the bottom surface of the wear-resistant layer 1 is fixed to the top surface of the decorative layer 2 Connection, the bottom surface of the decoration layer 2 is fixedly connected with the top surface of the base material layer 3, the bottom surface of the base material layer 3 is fixedly connected with the top surface of the balance layer 4, the bottom surface of the balance layer 4 is fixedly connected with the top surface of the mute layer 7, mute A through hole 8 is opened on the layer 7, and the activated carbon 5 is fixed in the through hole 8, and the top surface of the air-permeable interlayer 6 is fixedly connected with the bottom surface of the silent layer 7. The sound-absorbing layer 7 is a light-weight foam ...

specific Embodiment approach 3

[0008] Specific embodiment three: (see Fig. 5) this embodiment is made up of wear-resistant layer 1, decorative layer 2, base material layer 3, balance layer 4, activated carbon layer 5 and breathable interlayer 6, the bottom surface of wear-resistant layer 1 and decorative The top surface of layer 2 is fixedly connected, the bottom surface of decorative layer 2 is fixedly connected with the top surface of base material layer 3, the bottom surface of base material layer 3 is fixedly connected with the top surface of balance layer 4, and the activated carbon layer 25 is fixed on the bottom surface of balance layer 4 On the lower side of the activated carbon layer 5, the breathable interlayer 6 is fixed. Compared with Embodiment 1 and Embodiment 2 of this embodiment, the activated carbon itself has a larger area exposed to the air, which is more conducive to the adsorption, filtration and removal of harmful gases. The production method of this embodiment is as follows: 1. Press ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com