Module testing method and system

A technology of module testing and testing time, applied in electronic circuit testing, digital circuit testing, detecting faulty computer hardware, etc., can solve the problems of low testing efficiency, waste of testing cost, poor flexibility, etc., to save testing cost and improve The effect of testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

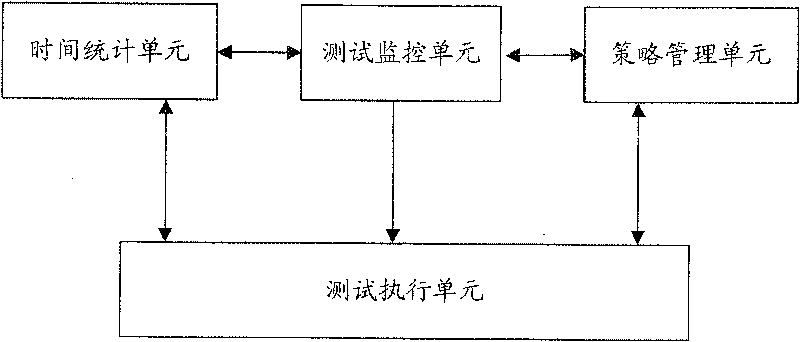

[0028] The basic idea of the present invention is: record the test time of the script in the module during the module test process, and monitor the test running situation of the module according to the standard test time of the script in the module, if the monitoring finds that the test running situation of the module is abnormal, then Automatically execute the pre-set corresponding processing strategies. The present invention will be described in further detail below in conjunction with specific embodiments, ie, accompanying drawings.

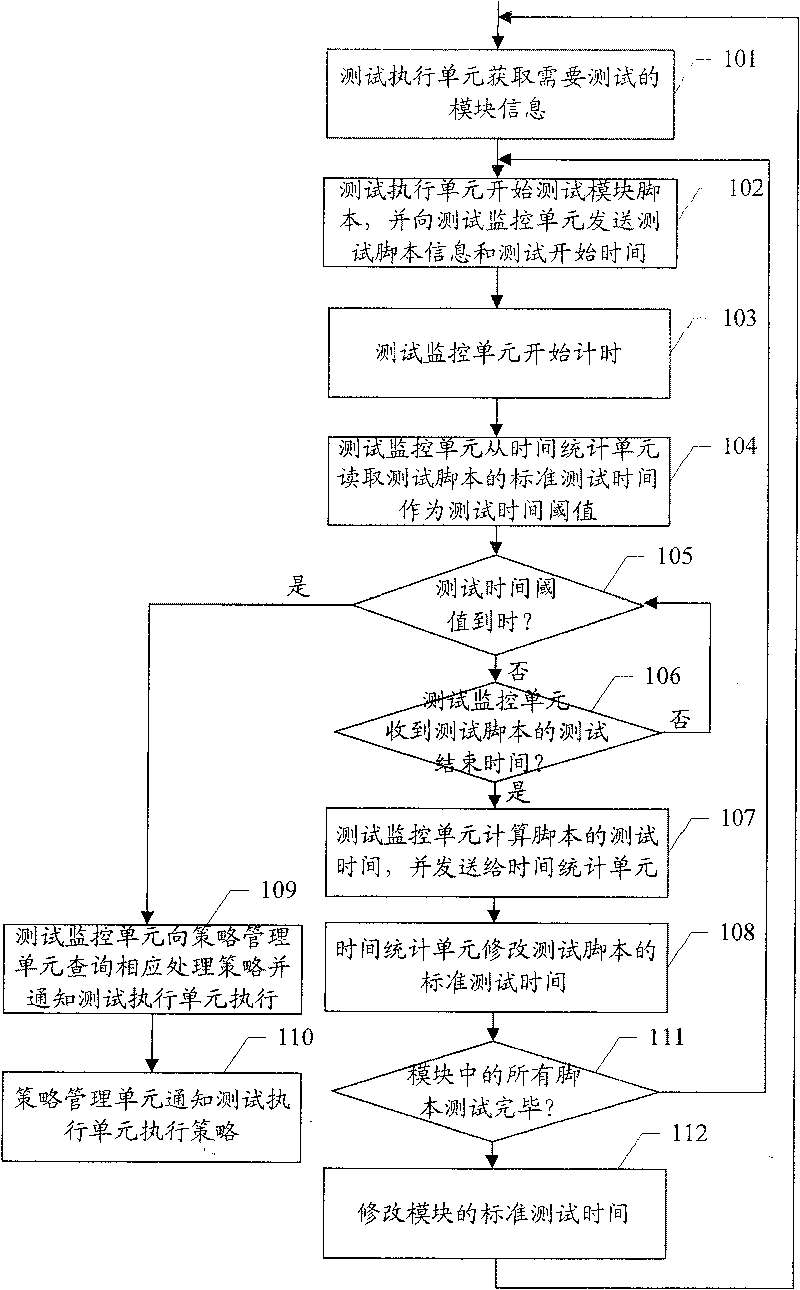

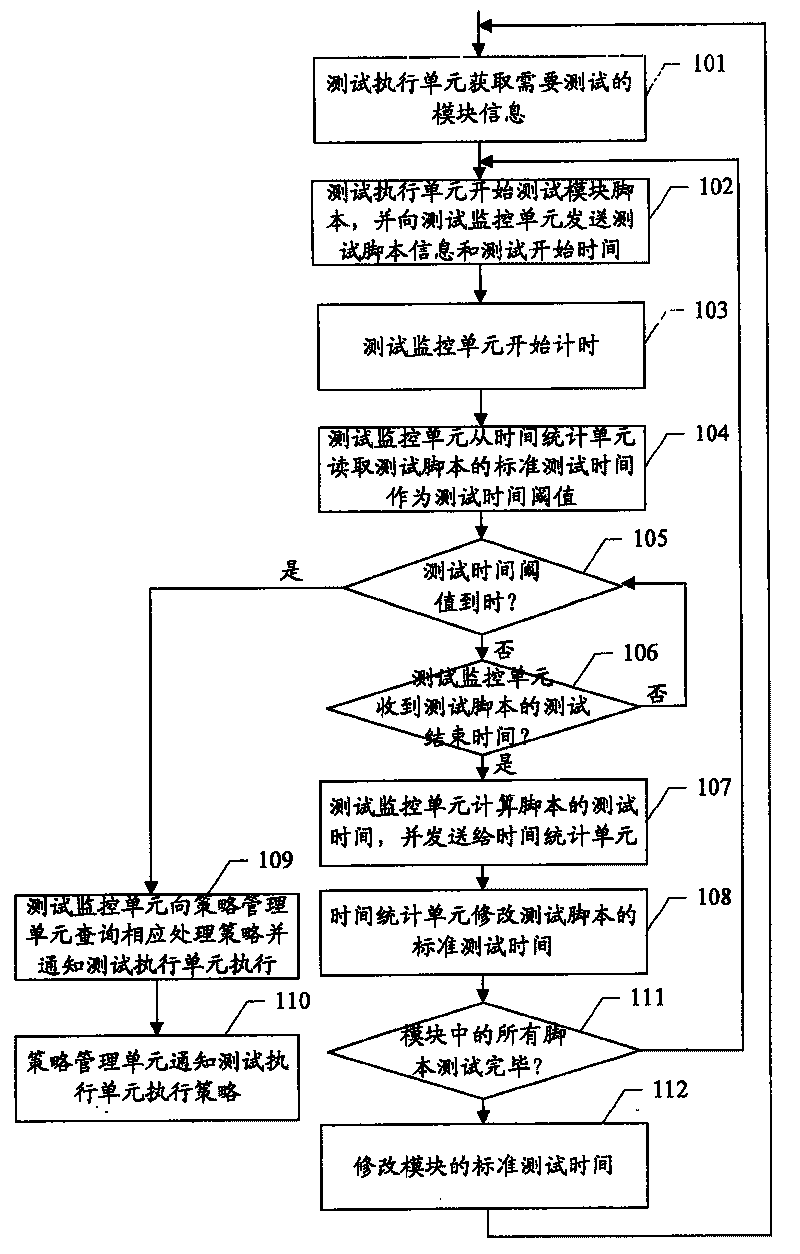

[0029] figure 1 Be the module test method flowchart of the present invention, as figure 1 Shown, module test method of the present invention comprises the following steps:

[0030] Step 101: The test execution unit obtains the information of the modules to be tested.

[0031] Here, testers can set the module test order in the time statistics unit according to actual needs. For example, when the test time is limited, the module tests can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com