Method for electrolysis of molten salt, electrolytic cell, and process for producing ti using said method

A technology of molten salt electrolysis and molten salt, which is applied in the manufacture of Ti and the field of electrolytic cells, can solve the problems of high price and achieve the effect of high-efficiency manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

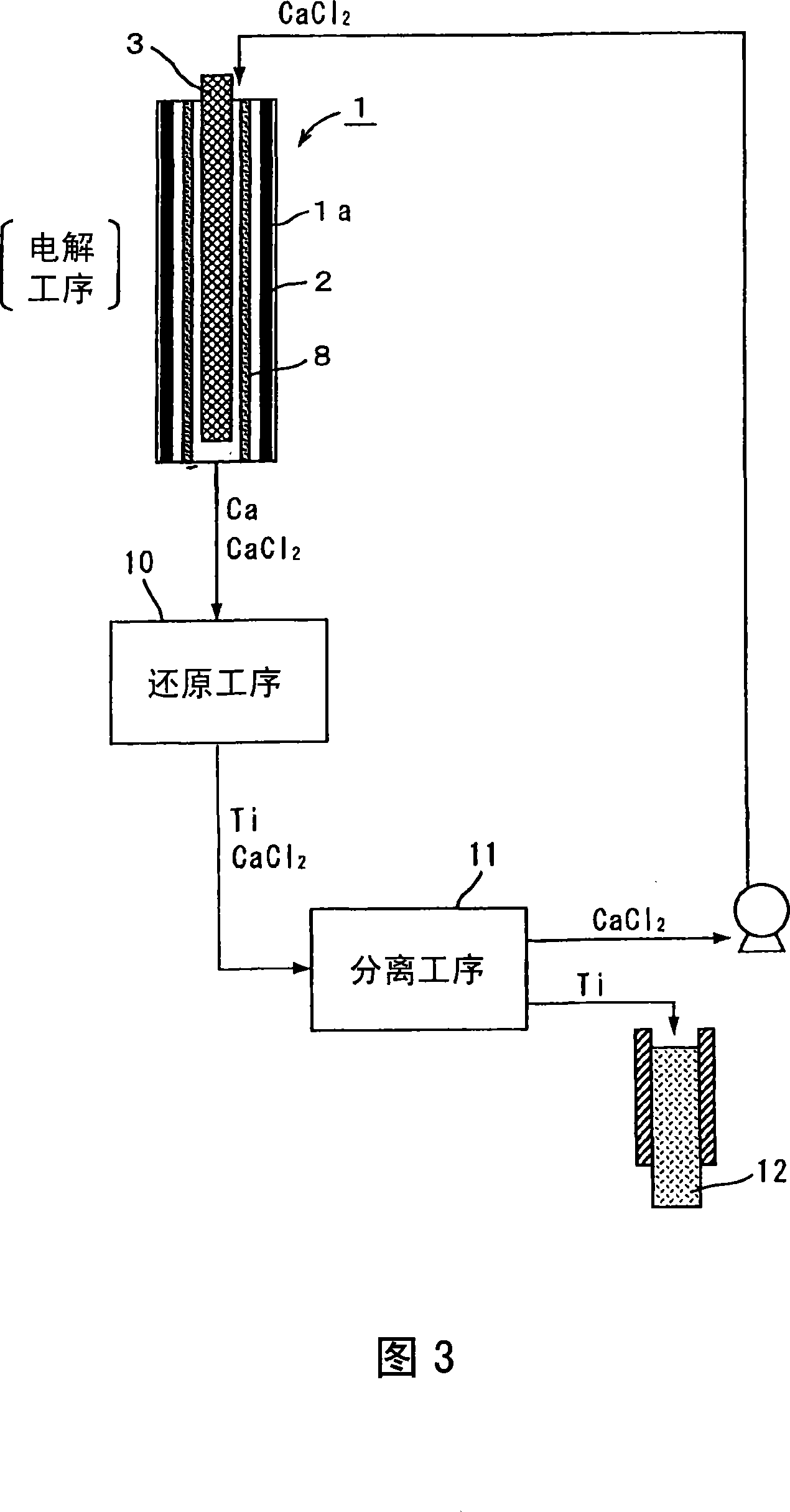

[0029] The molten salt electrolysis method of the present invention, the electrolytic cell, and the method for producing Ti to which the method is applied will be described in detail below with reference to the accompanying drawings. Also, in the molten salt electrolysis method of the present invention, the metal mist forms the metal in reducing TiCl 4 It also functions when Ti is formed, so the case where Ca is the metal mist forming metal will be described below.

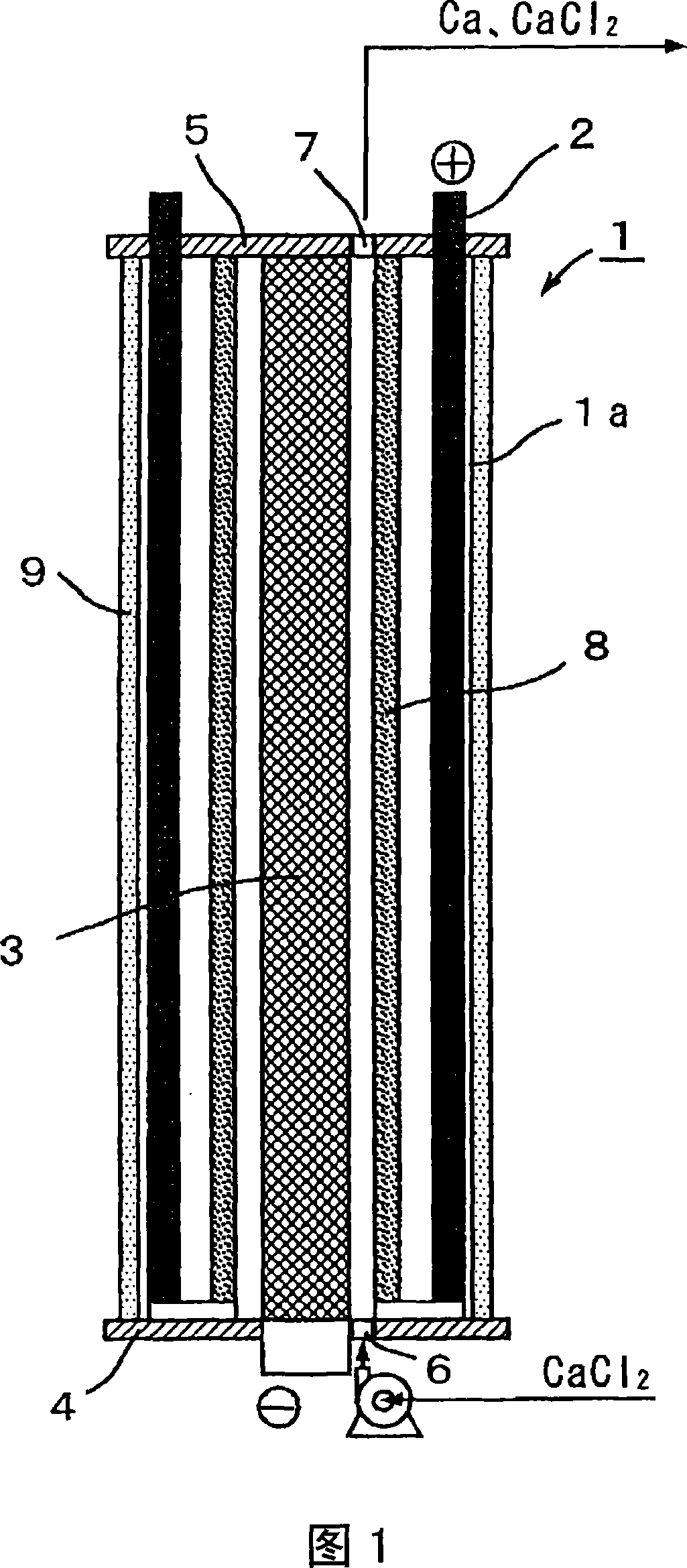

[0030] FIG. 1 is a cross-sectional view showing a configuration example of a main part of an electrolytic cell used for carrying out the molten salt electrolysis method of the present invention.

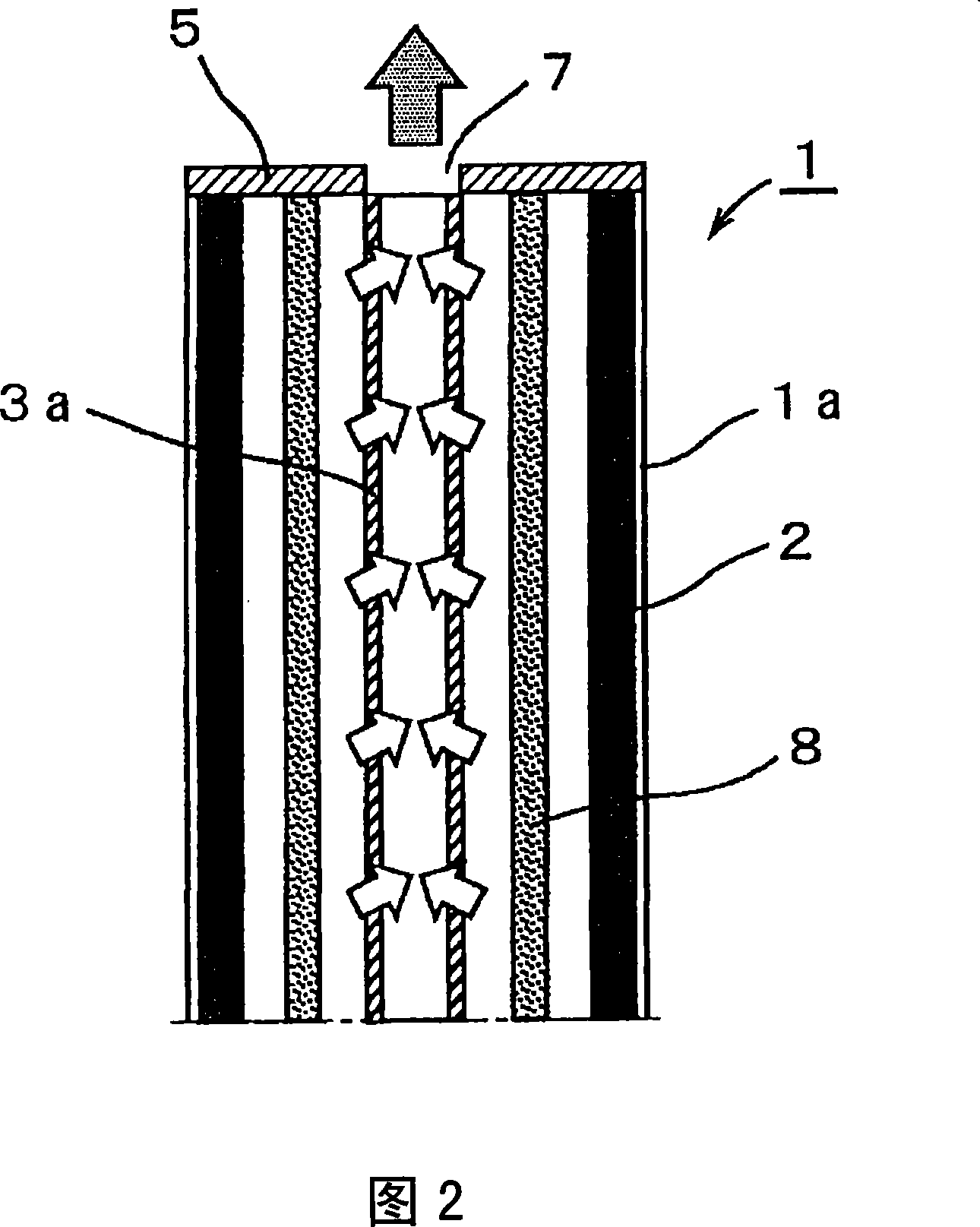

[0031] The electrolytic cell 1 has: keep the CaCl 2 A pipe (cylindrical)-shaped electrolytic cell container 1a long in one direction for molten salt; a cylindrical anode 2 and a columnar negative electrode 3 arranged in the container 1a along the longitudinal direction of the electrolytic cell container 1a, A molten sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com