One-way boosting buffer mechanism for electronic jacquard opening mechanism

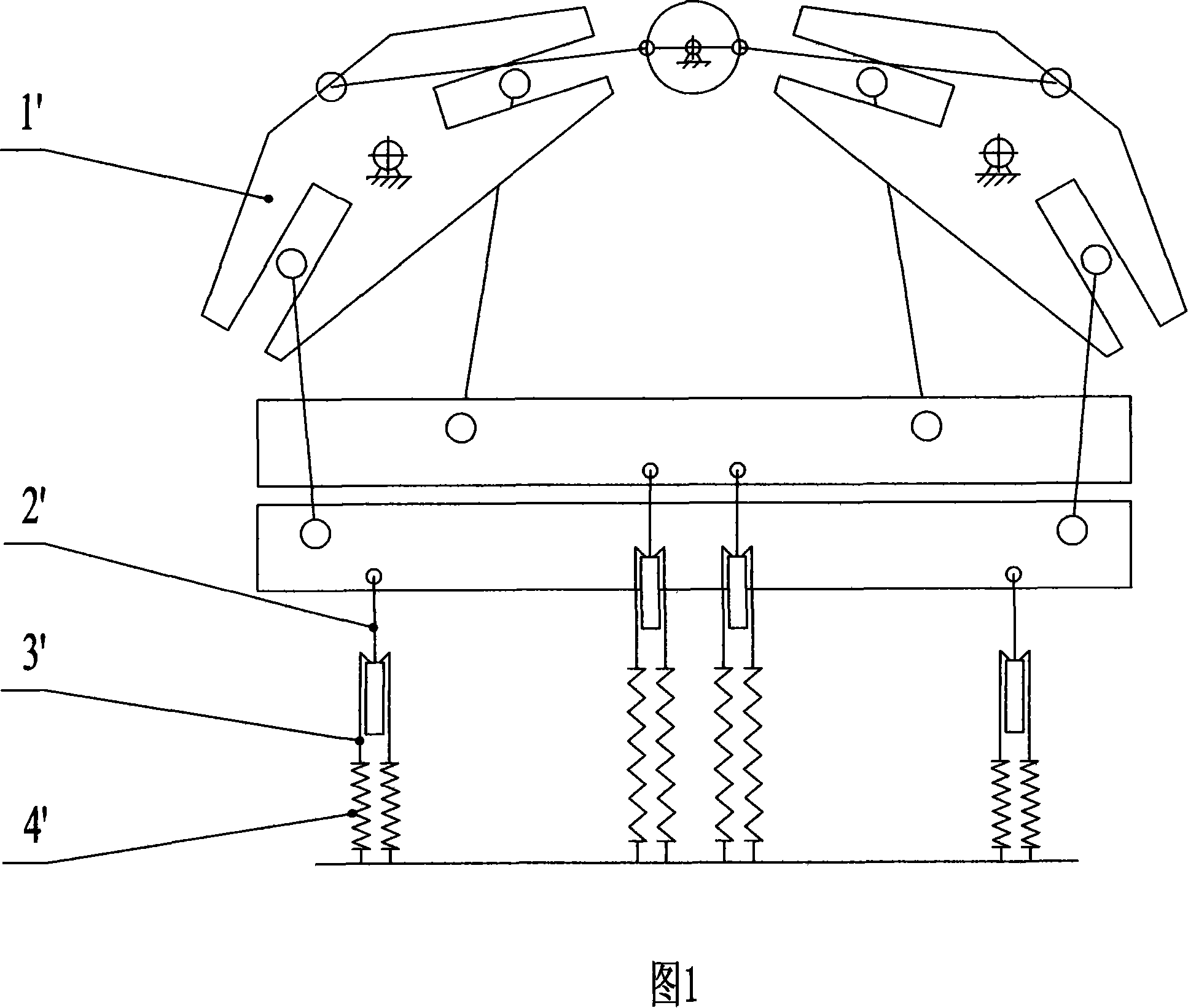

An opening mechanism and electronic jacquard technology, applied in other opening mechanisms, jacquard machines, textiles, etc., can solve problems such as the inability to effectively solve the problems of broach boosting and impact, increasing driving load impact, weakening effect, etc. Uneven load and impact noise, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

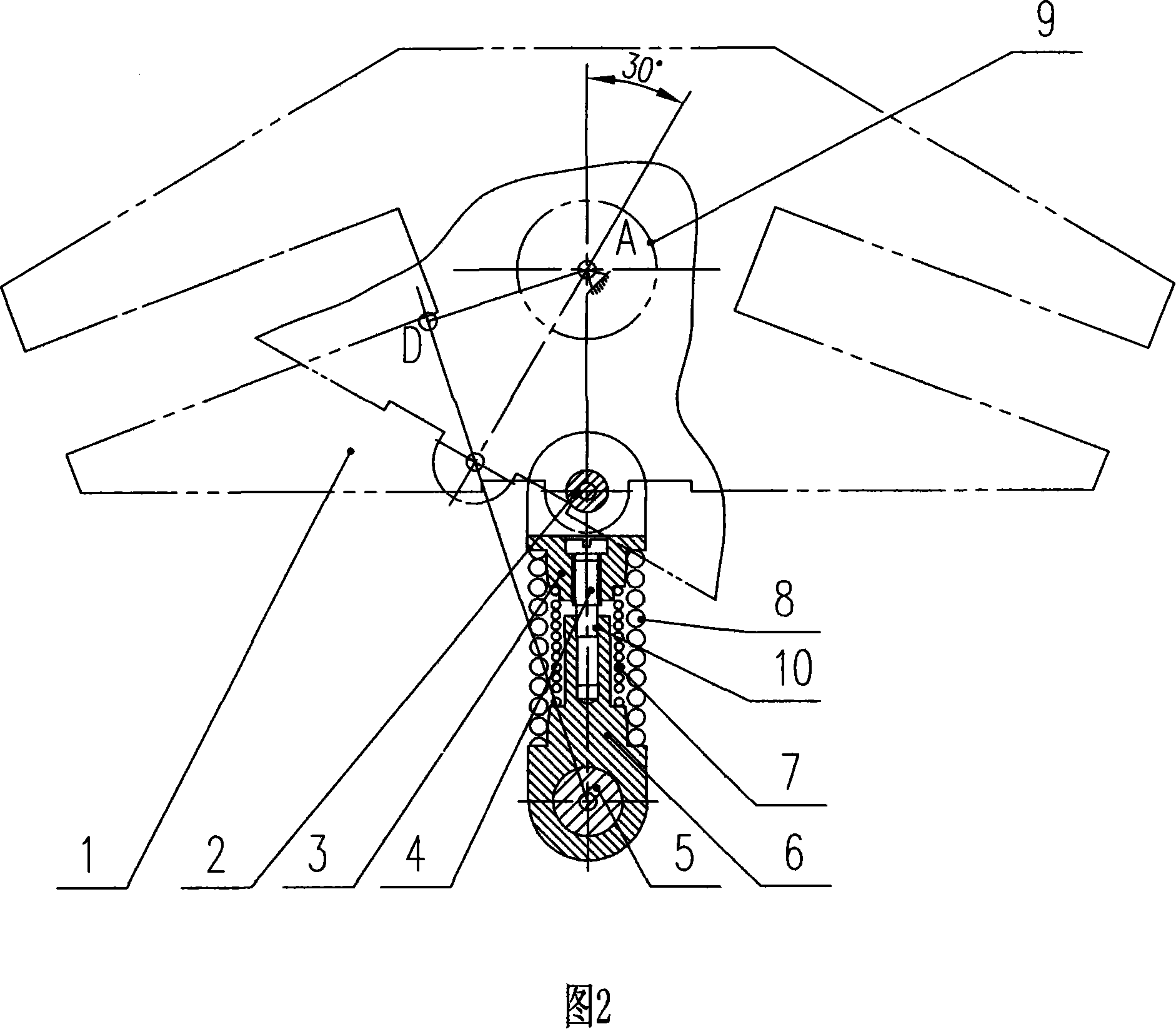

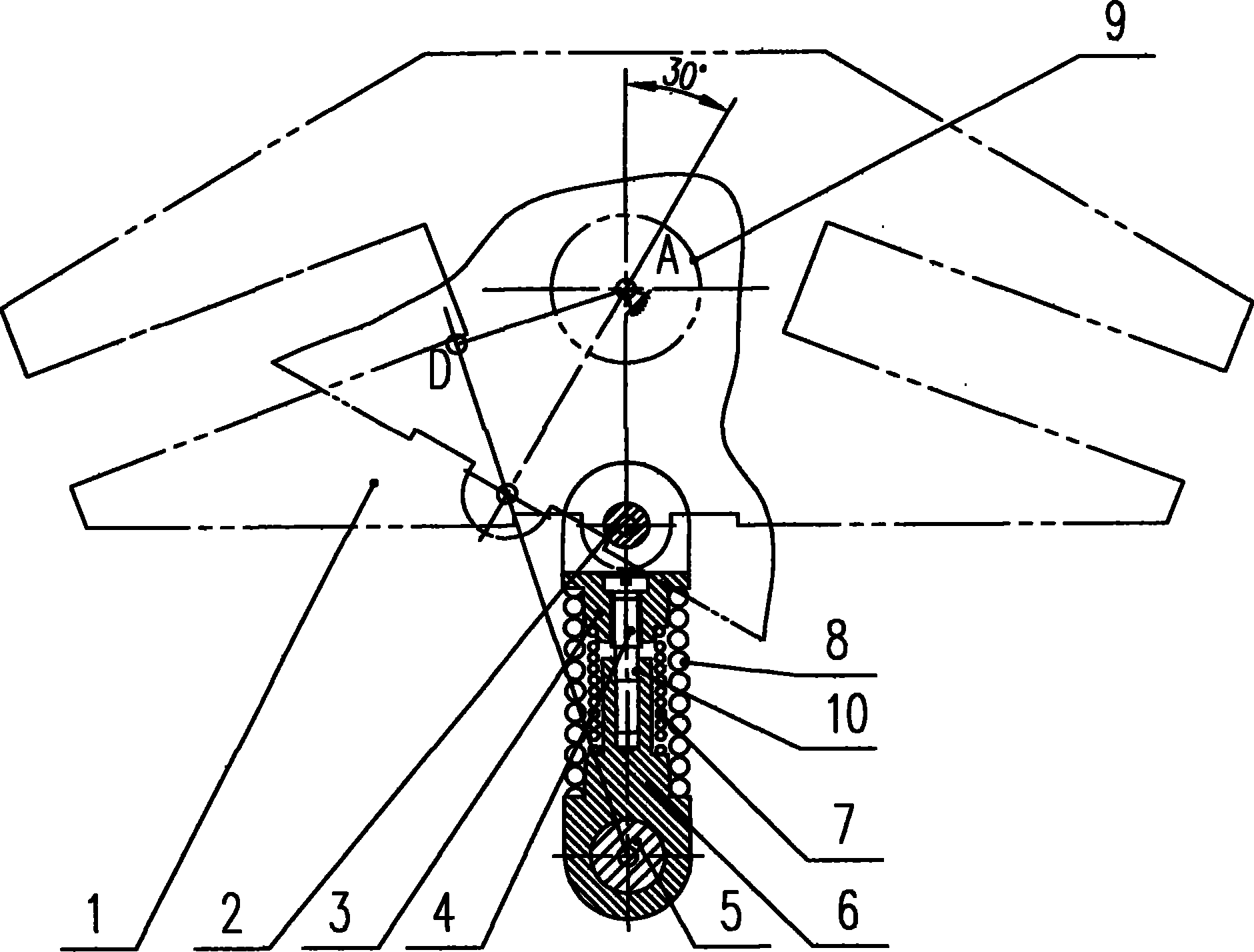

[0013] As shown in Figure 2, the one-way boost buffer mechanism in the opening mechanism of the electronic jacquard machine of the present invention includes a guide screw 4 installed between the upper seat 3 of the compression spring and the lower seat 6 of the compression spring and arranged outward from the middle, an internal pressure Spring 7, outer compression spring 8. The upper end of the guide screw 4 is fixed on the upper seat 3 of the stage clip, and the lower end of the guide screw 4 is positioned in the guide hole 10 of the lower seat 6 of the stage clip. The guide screw 4 guides the relative movement of the upper seat 3 of the stage clip and the lower seat 6 of the stage clip. The upper seat 3 of the stage clip is hinged on the lower end when the lifting rocker 1 is in the comprehensive level position by the upper shaft 2 of the stage clip, and the lower seat 6 of the stage clip is hinged on the wallboard by the lower axle 5 of the stage clip. The axis of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com