Vertical-column pressurized hydraulic vulcanizing machine

A vulcanizer and column technology, applied in the field of column pressurized hydraulic vulcanizers, can solve the problems such as heavy weight of lower pallets, molds and tires, unfavorable design of afterburner cylinders, and increase of thrust of cylinders, and achieve fast afterburner speed. , Short working stroke, the effect of reducing inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

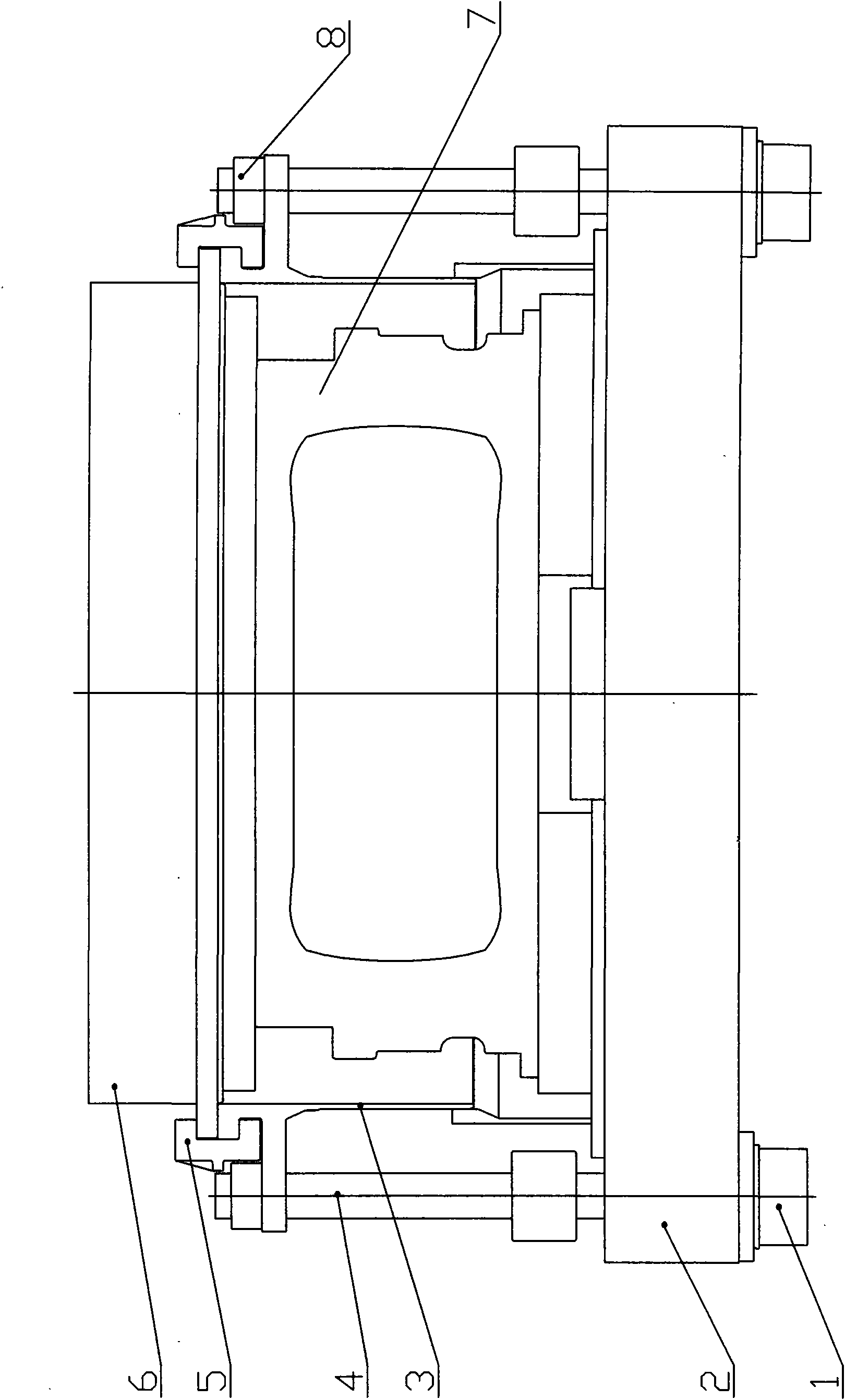

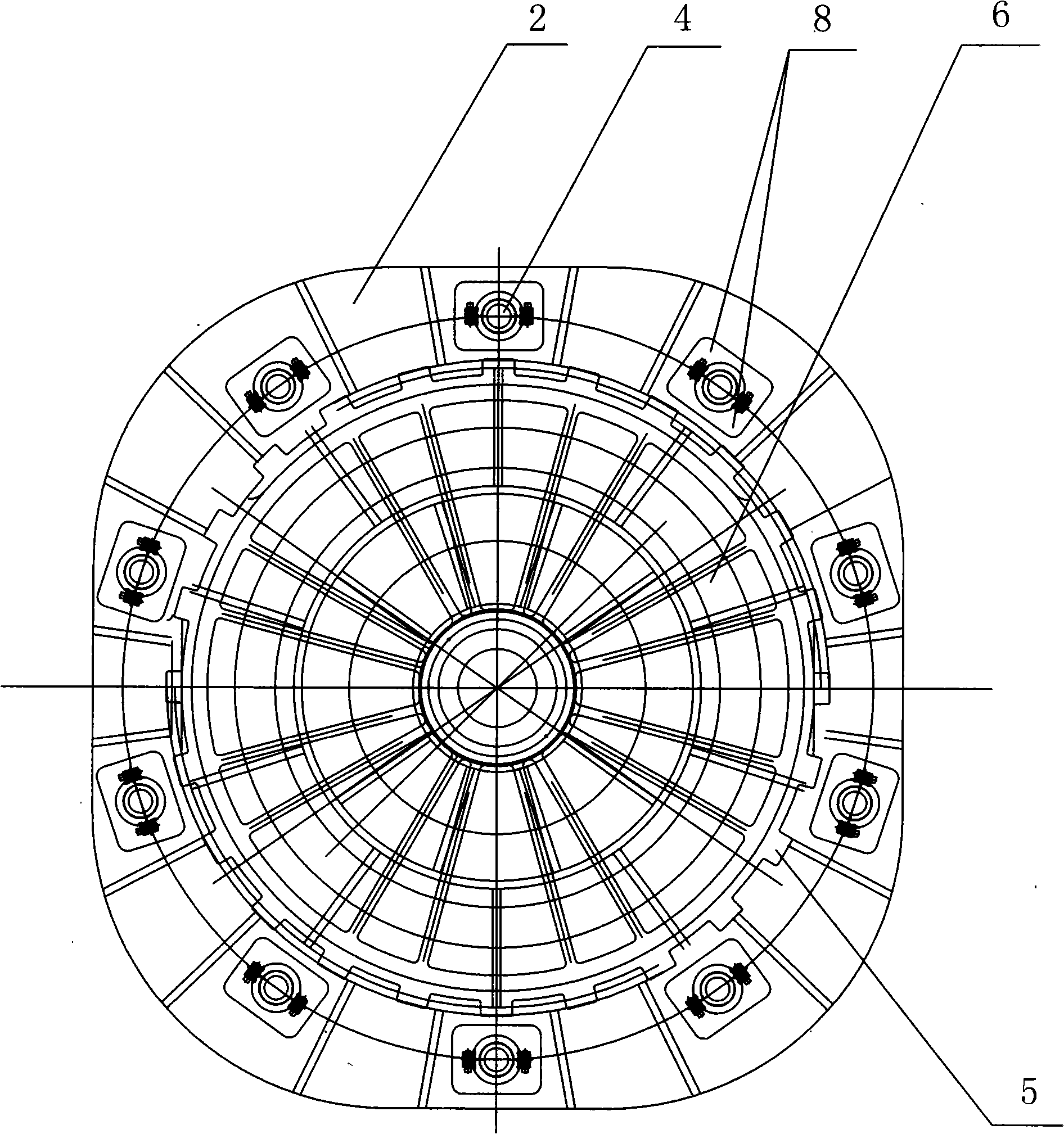

[0026] The column pressurized hydraulic vulcanizer of the present invention comprises a base 2, a vulcanization chamber 3, a gear ring 5, a beam cover 6, an afterburner cylinder 1, a column 4, an afterburner cylinder 1, a mold 7 and two half rings 8.

[0027] Figure 1, figure 2 As shown, 10 columns 4 are evenly distributed around the vulcanization chamber 3 in a circular equidistant manner. The upper end of the column 4 is fixed to the staggered ring 5 through two half-rings 8, and the lower end of the column 4 is connected to the piston rod of the booster cylinder 1. 10 The cylinder body of the booster cylinder 1 is fixed on the base 2, and its position corresponds to 10 columns 4, and each booster cylinder 1 can pressurize each column 4 separately.

[0028] As shown in Figure 1, above the base 2 is the vulcanization chamber 3. After the cross beam cover 6 is covered, turn the gear ring 5, and the teeth of the gear ring 5 will be engaged with the teeth of the beam cover 6 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com