Re-design of hospital operating room

An operating room, operating table technology, applied in the field of operating room configuration, can solve the problems of confusion, inefficient lighting / sterile state, crowding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

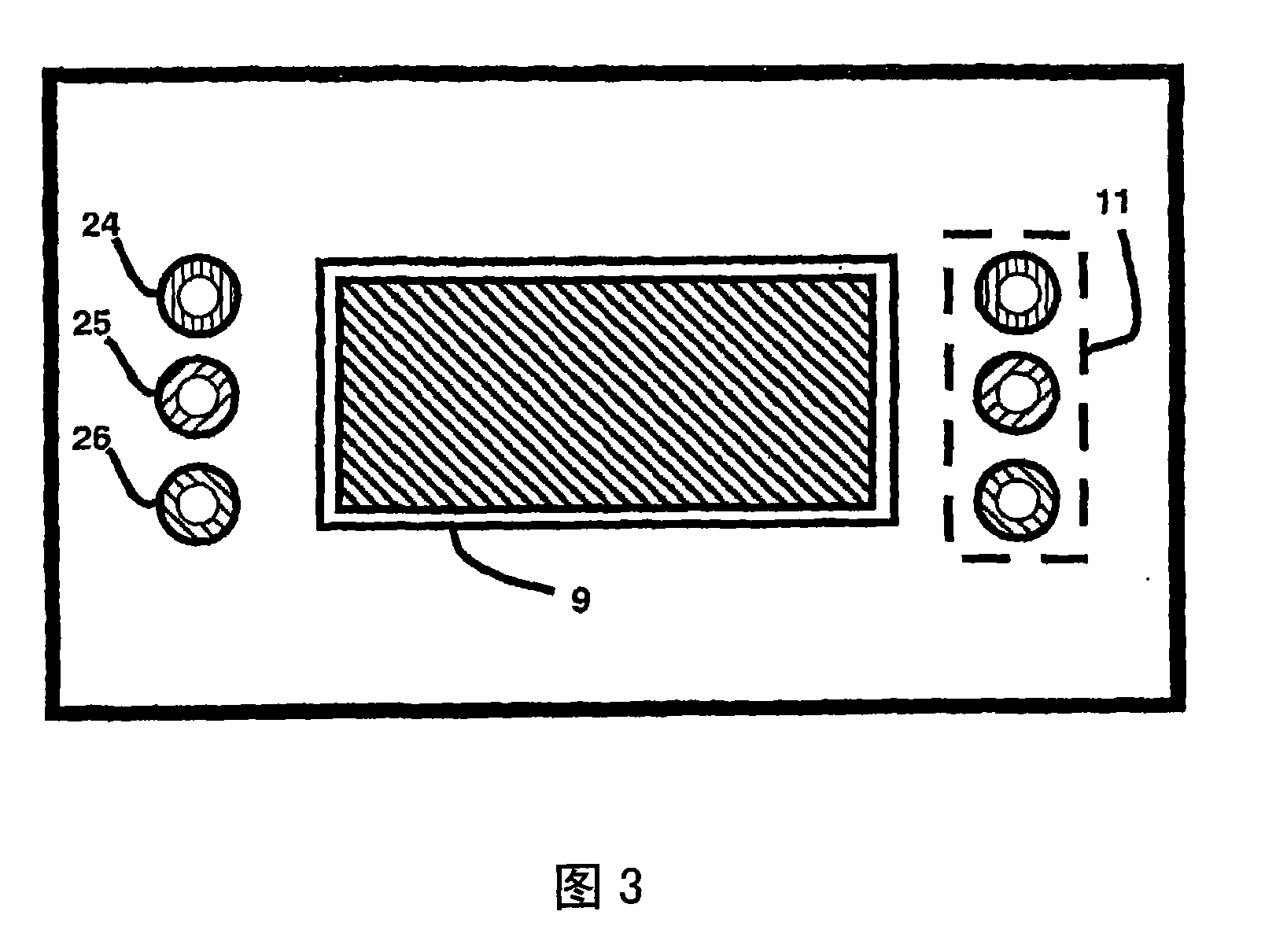

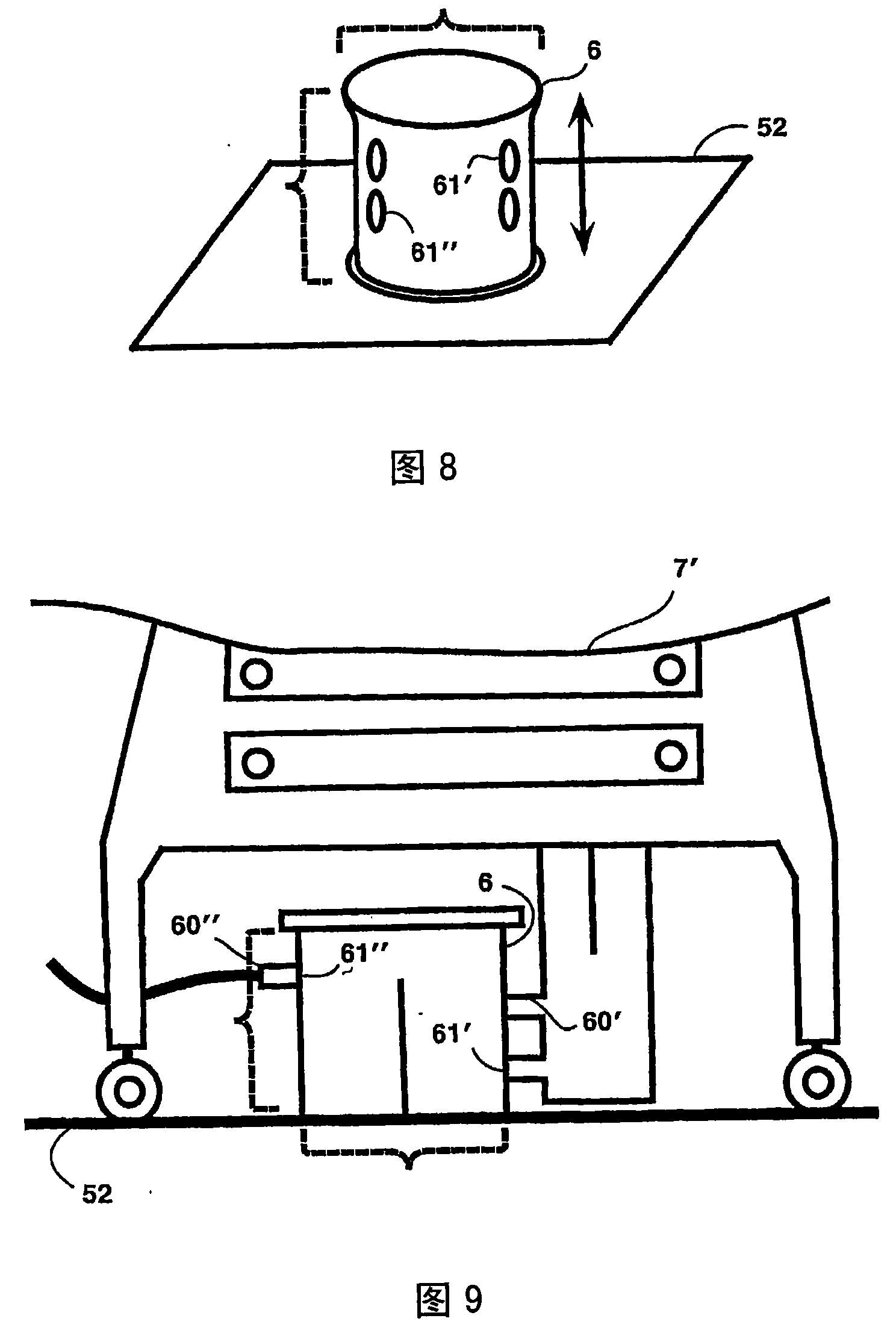

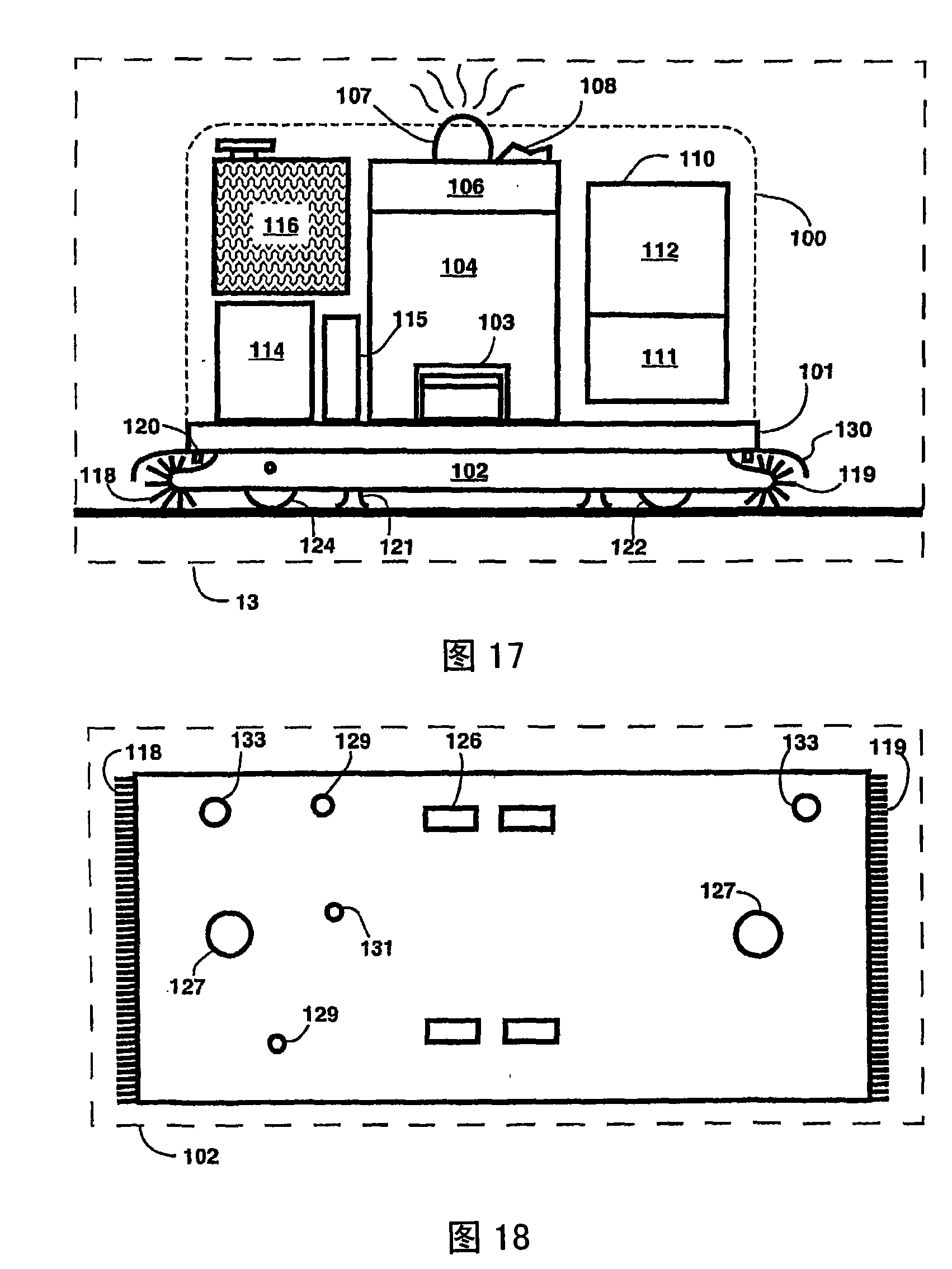

[0090] As shown in Figures 1-19, an operating room in a medical facility is described that has no electrical wires, high voltage cables or hoses exposed to the working environment in the operating room. In various embodiments thereof, the operating room includes one or more of the following:

[0091] 1. Walls having corners and ceilings, at least one of said walls including a built-in compartment for supplies, said compartment being adapted to be accessible from inside and outside said operating room, and in said wall At least one has an inner wall container for disposal of biological agents, sharps and waste.

[0092] 2. Sub-floor and finished floor, optionally, the finished floor is supported by interlocking floor support columns, each column is tenoned with the adjacent column; optionally, The surface floor may be raised to provide a sub-flooring under the floor supported by concrete or other material.

[0093] 3. At least one box with a facility connection for supplying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com