Method for optimizing aluminium electrolysis slot field

An optimization method and technology for an aluminum electrolytic cell, applied in the field of optimizing the magnetic field of an aluminum electrolytic cell, can solve the problems of reduced current efficiency, increased power consumption, uneven distribution of the electrolytic cell magnetic field, etc., to achieve the effect of reducing the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

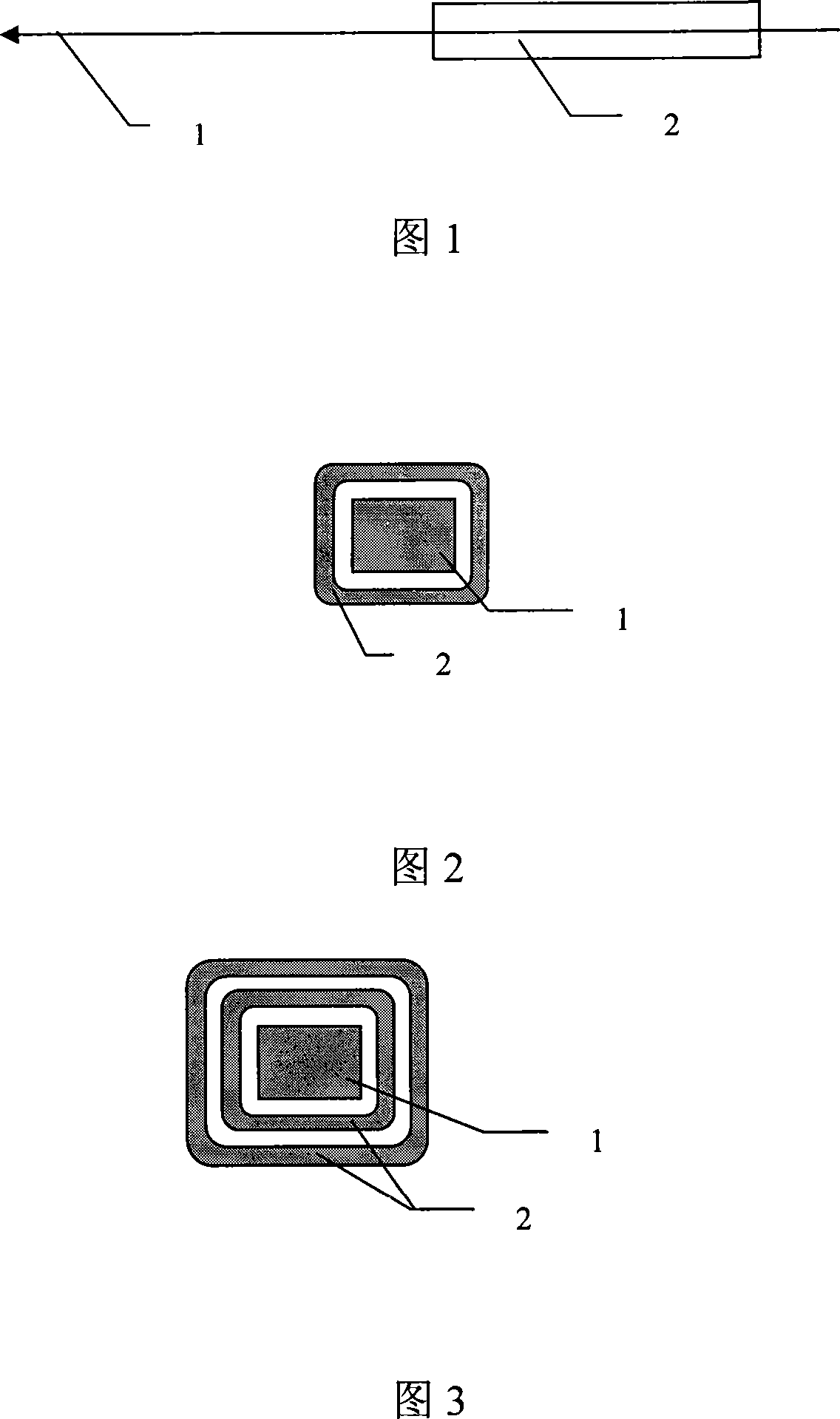

[0015] The vertical magnetic field Bz of the aluminum liquid layer in the tank generally has a maximum value at the four corners, and is close to antisymmetric about the X and Y axes. When the compensation bus 1 is at the end of the electrolytic cell from the power inlet side to the power outlet side, the The direction of the vertical magnetic field is positive, which will cause the positive maximum value at the corner of the incoming side to increase when the bus bar compensates the negative Bz on the outgoing side. In order to reduce the impact on the right side of the electric incoming surface, We add a shielding cover 2 to the corresponding part of the busbar. The shielding cover is determined to be a single-layer shielding cover according to the needs. The cross-section is shown in Figure 2. The shielding cover can also be multi-layered, as shown in Figure 3.

[0016] If a single-layer shield is used, when the cross-section of the compensation busbar 1 is 300mm×200mm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com