Motor control circuit and method as well as brushless motor system

A motor control and motor technology, applied in the control system, electronic commutation motor control, single motor speed/torque control, etc., can solve the problems of general products and methods without suitable structures and methods, inconvenience, etc.

Active Publication Date: 2010-11-24

PROLIFIC TECH INC

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that the above-mentioned existing motor control method, motor control circuit and brushless motor system obviously still have inconvenience and defects in product structure, control method and use, and need to be further improved urgently.

In order to solve the above-mentioned problems, the relevant manufacturers have tried their best to find a solution, but no suitable design has been developed for a long time, and there is no suitable structure and method for general products and methods to solve the above-mentioned problems. This is obviously a problem that relevant industry players are eager to solve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

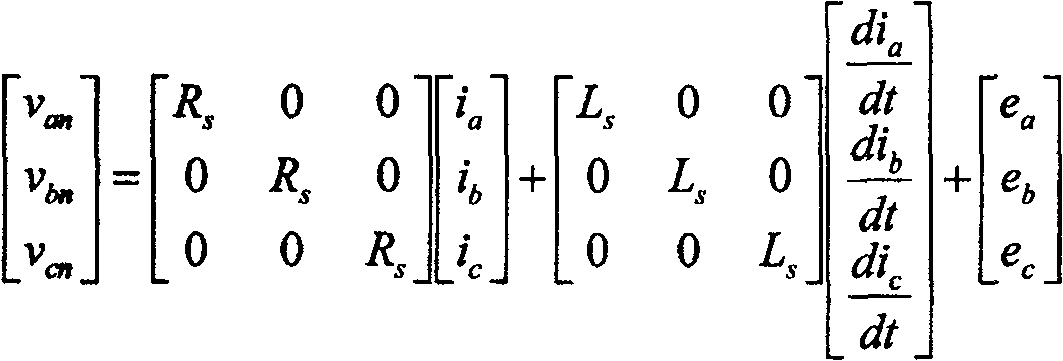

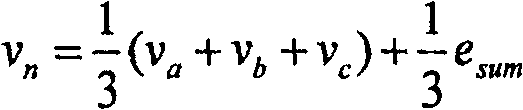

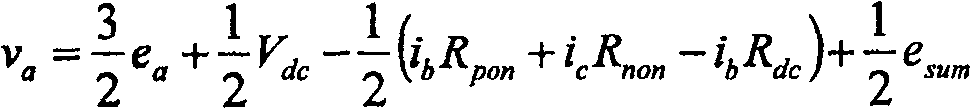

The invention relates to a motor control circuit and a brushless motor system, and provides a motor control method, circuit and brushless motor. The motor includes a three-phase coil, the first terminal of each coil is coupled at a node jointly. The method includes: when no current go through a first specific coil in the three-phase coil, and when the current flows from the second terminal of thesecond specific coil to the second terminal of the third specific coil, detecting the voltage at the second terminal of the first specific coil as a first appointment voltage; detecting the potentialdrop of the DC sensing resistor as a second appointment voltage; estimating the zero-cross point by the first appointment voltage, the second appointment voltage and the DC voltage supplied to the motor so as to control the motor. The invention is capable of detecting the zero-cross point of the motor in the PWM-off state, which further controls the phase change of motor, in addition, the invention can detect the zero-cross point by conjunction with PWM-off, thereby decreasing the phase change error, which is very practical.

Description

Motor control circuit and method and brushless motor system Technical field The invention relates to a motor control technology, in particular to a motor control method, a motor control circuit and a brushless motor system. Background technique Adjustable speed motors are widely used in factory automation systems, ventilation systems, air conditioning systems, and so on. The conventional adjustable speed motor is a motor in the form of a brush, and a brush-commutator is configured on this motor. For the past century, the commutation of a brushed motor has been realized by graphite brushes and a ring commutator mounted on the runner. However, the above-mentioned brushed motor is relatively heavy, generates a lot of noise during operation, and is inefficient. With the increasing advancement of science and technology, some people have developed Brushless-Motor, and benefited from the advancement of design and material technology, its price has dropped sharply. Today, the cost ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02P6/18H02P6/08H02P6/182

Inventor 郑光耀

Owner PROLIFIC TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com