Combination double bottom hook block

A combined and dual technology, applied in the direction of portable lifting devices, hoisting devices, load hanging components, etc., can solve the problems of reducing the lifting height, increasing the pulley block and lower pulley mechanism of the crane, etc., to save costs and use more effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

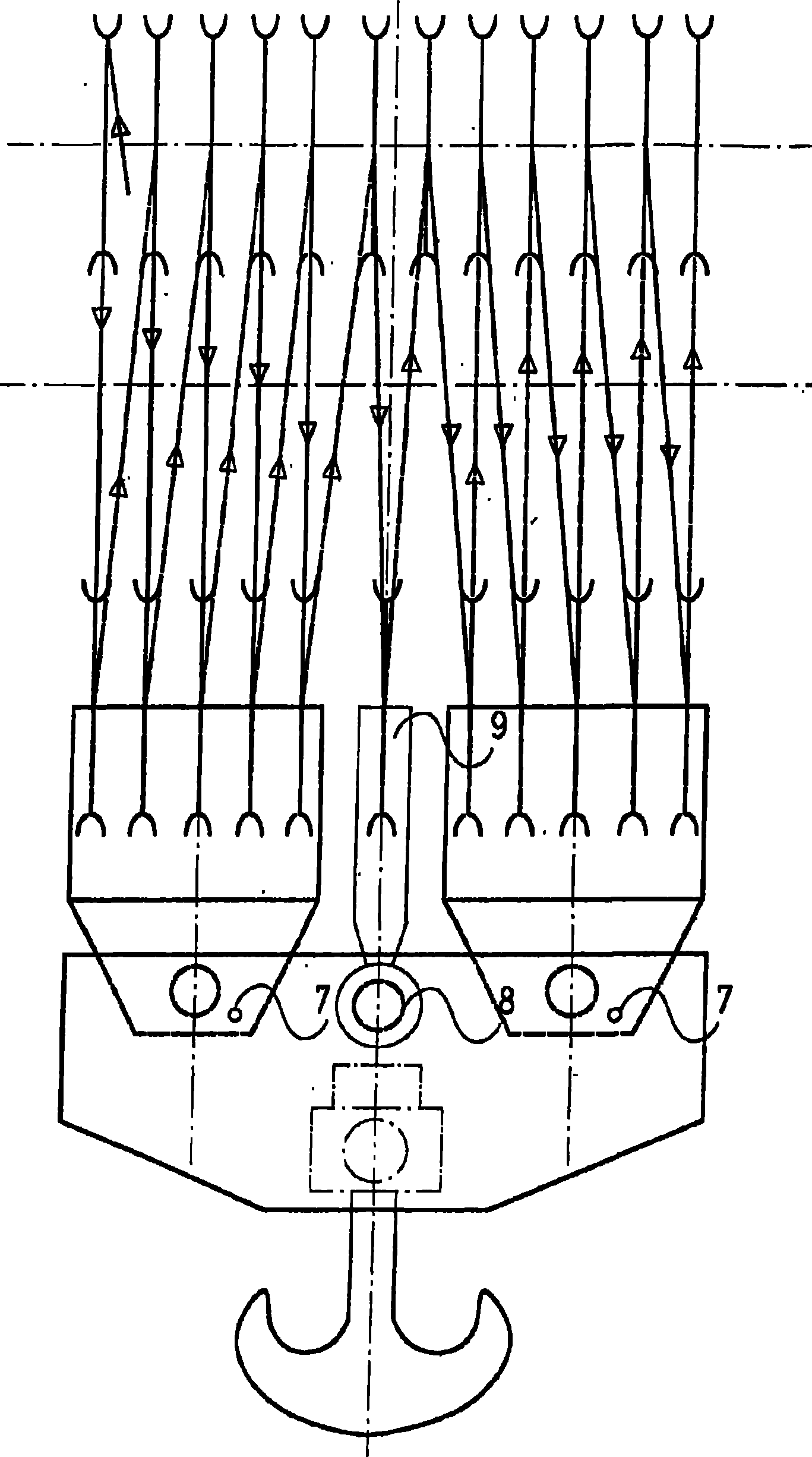

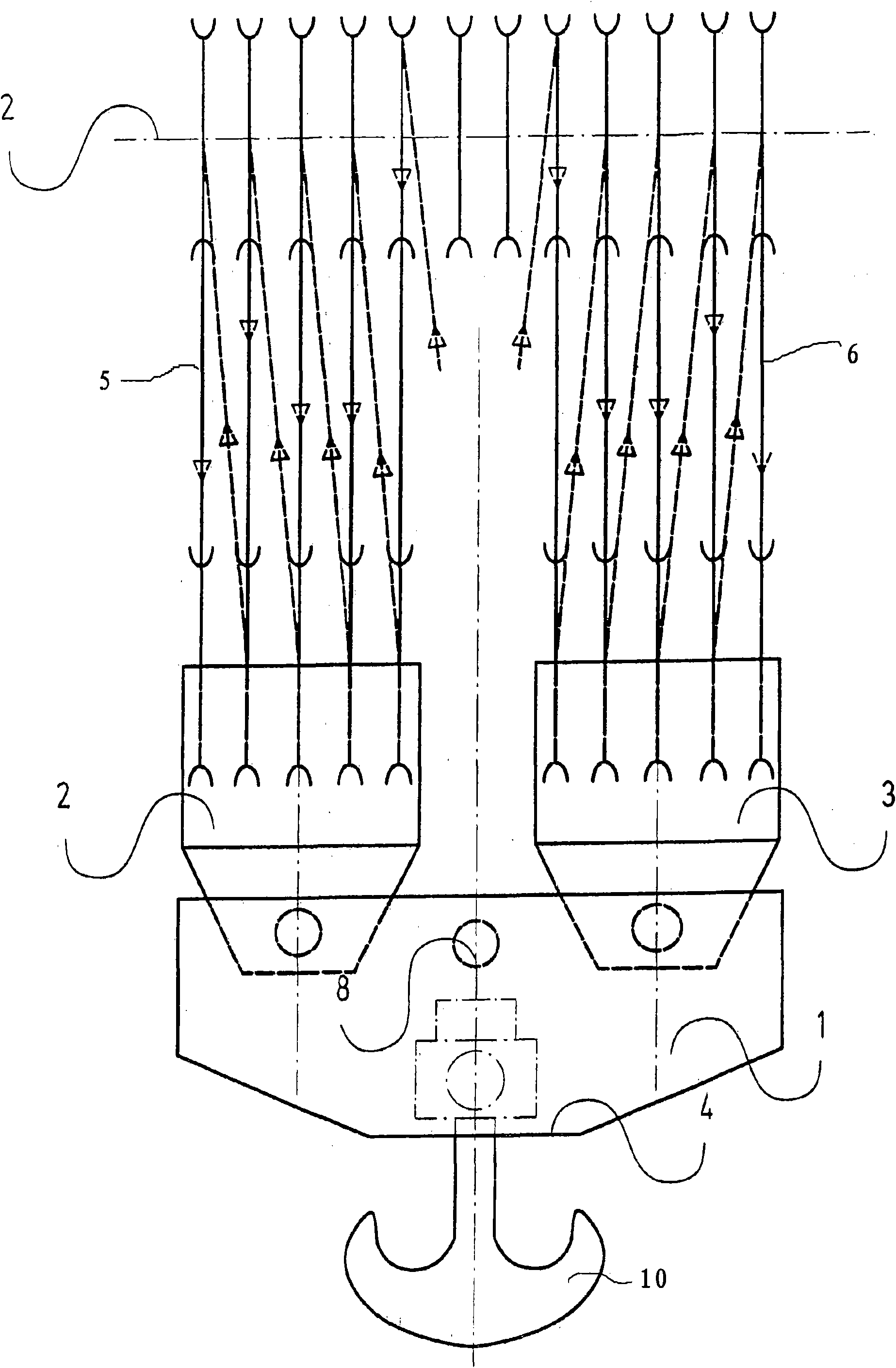

[0040] FIG. 2 shows the general design of the double lower pulley mechanism 1 , in which the two pulley sets 2 and 3 are connected by a rocker arm 4 . As can be seen from the rope guidance shown, two hoisting ropes 5 and 6 are arranged here. The hoisting hook connected to the rocker arm 4 is denoted by 10 .

[0041] This double lower pulley mechanism is for example designed for loads of 2 x 160 tons.

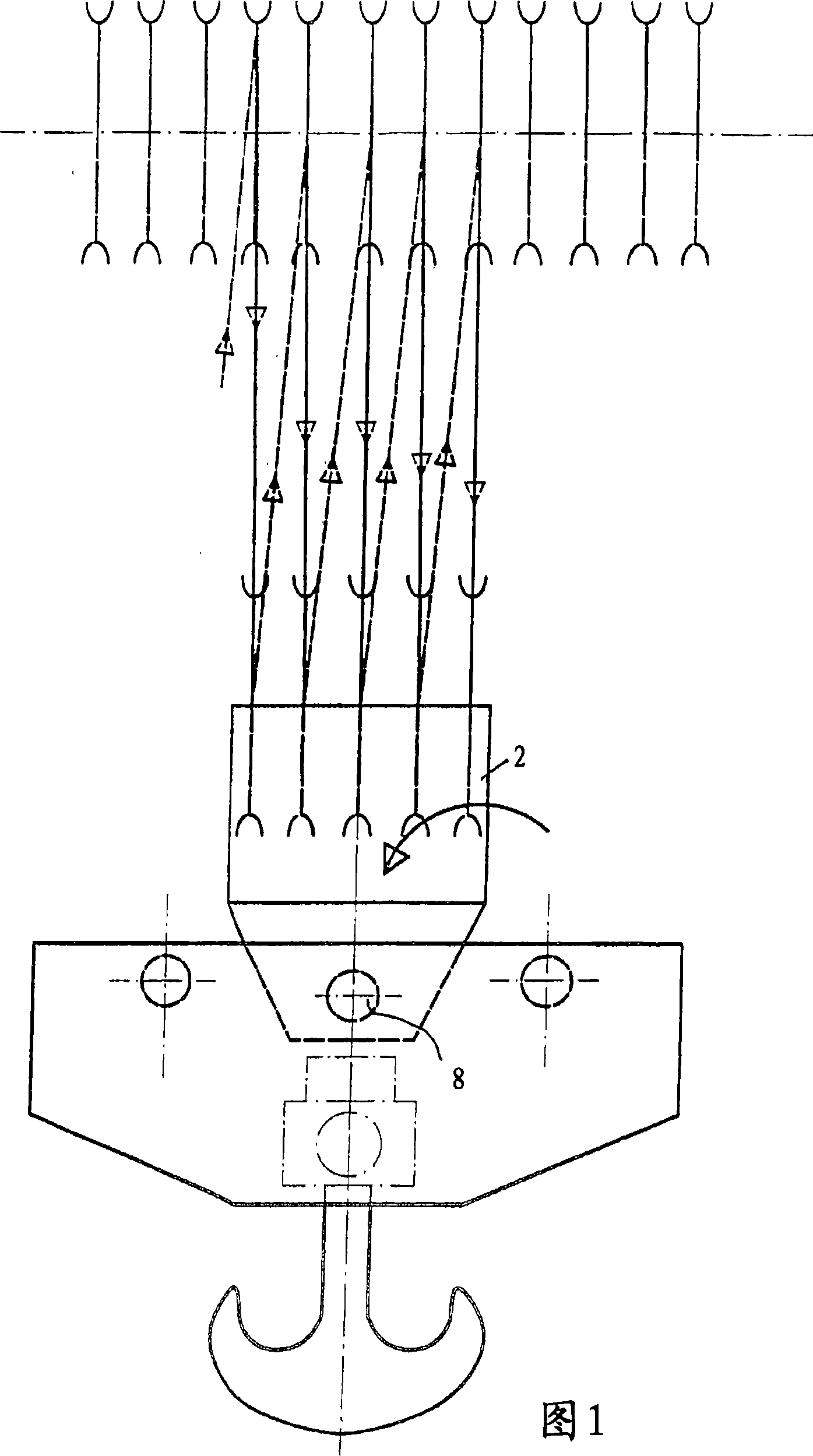

[0042] As shown in FIG. 1 , if a single pulley block 2 is used to replace the two pulley blocks 2 and 3 , the pulley block must be centrally arranged, and the existing mounting holes 8 can be used for this purpose.

[0043] At this time, the disadvantage is: the load bearing capacity should be halved, that is, to 1×160 tons.

[0044] In the case of using only one hoisting wire rope, the above-mentioned disadvantages can be avoided by the following measures: keep the usual two pulley blocks 2 and 3 on the rocker arm 4, but (as indicated by 7) use the bolts to prevent tilting F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com