Brittle fracture crack transmission resisting T-shaped welding joint construction with excellent crack arrest characteristic

A technology for welding joints and structures, applied in the direction of welding/welding/cutting objects, connecting components, welding equipment, etc., can solve problems such as difficult temperature distribution control, achieve clear welding construction methods and quality management methods, simple composition, and prevent brittleness The effect of crack propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

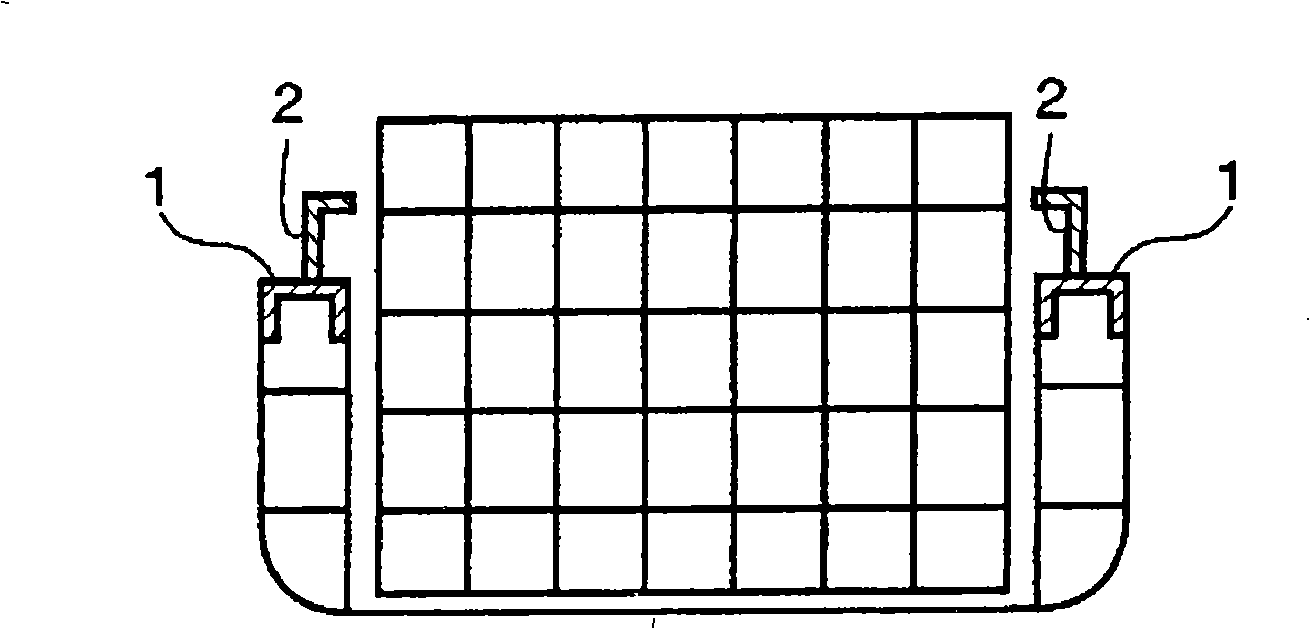

[0052]As the vertical member, a steel plate with an average pendulum absorbed energy of 70J or more at -20°C in the center of the plate thickness, which is welded by gas-electric welding is used, and steel plates with various characteristics are used as the horizontal member on top of it, and these are combined. Made T-welded joints (refer to the figure 2 ), the brittle failure test (ESSO test with a certain temperature) was carried out on the welded joint.

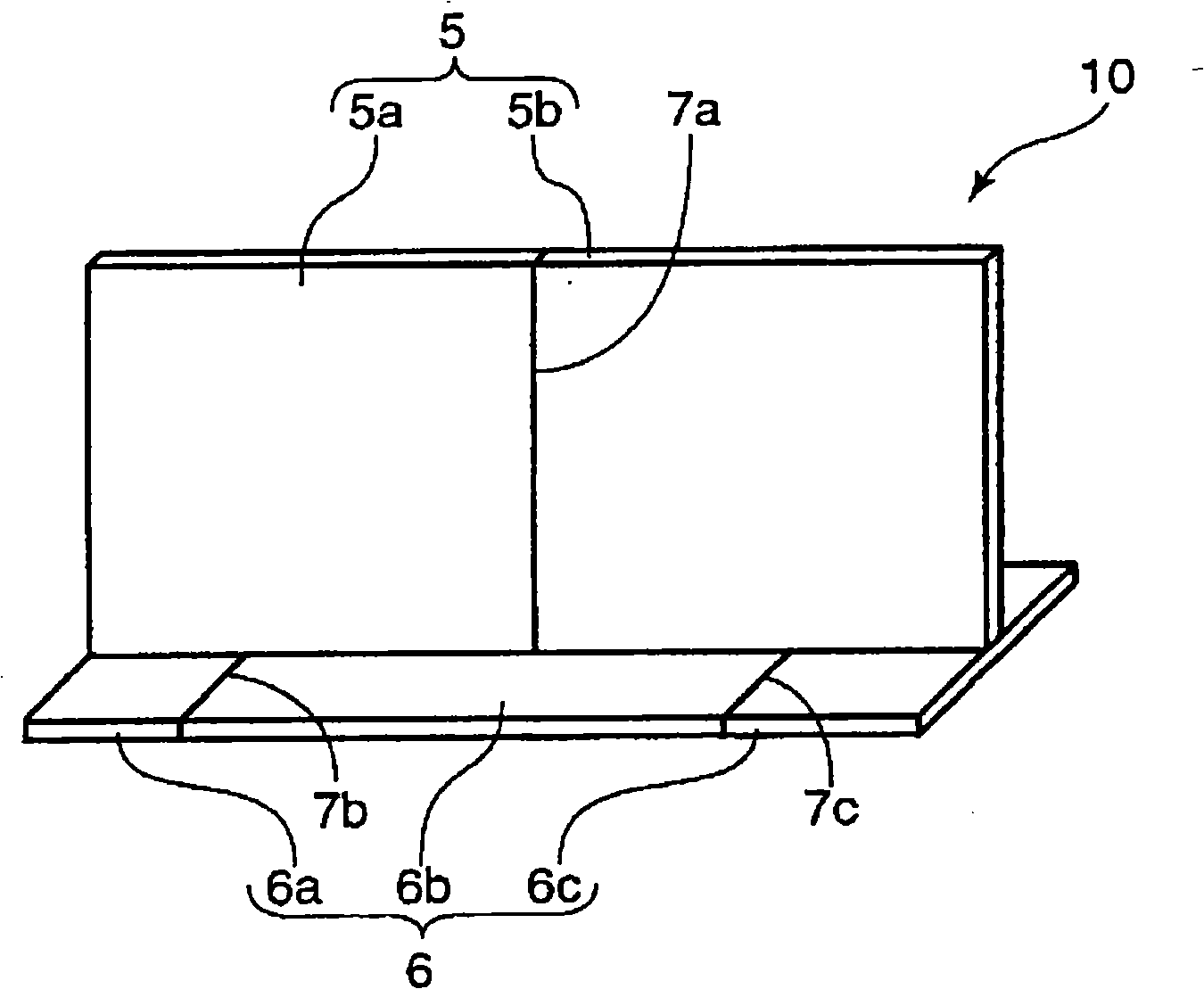

[0053] Figure 5 It is an explanatory diagram showing the above-mentioned test conditions. Among the figures, 20 shows a test body composed of a vertical member 5 and a horizontal member 6. On the bottom of the horizontal member 6, a steel plate for suppressing brittle fracture is fixed by welding (for example, carbon dioxide surfacing welding). Auxiliary steel material 16 for test body centrifugal. On the test body 20, the ribs 17a, 17b and the lead plates 18a, 18b are connected, and by applying the load in the opposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com