Ellipse LED

A light-emitting diode and elliptical technology, which is applied in the field of elliptical light-emitting diodes, can solve problems such as the limitation of illuminance, and achieve the effect of expanding the irradiation range and improving light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] refer to Figure 6 , is a perspective view of the first embodiment of the present invention.

[0036] refer to Figure 7 , is a side view of the first embodiment.

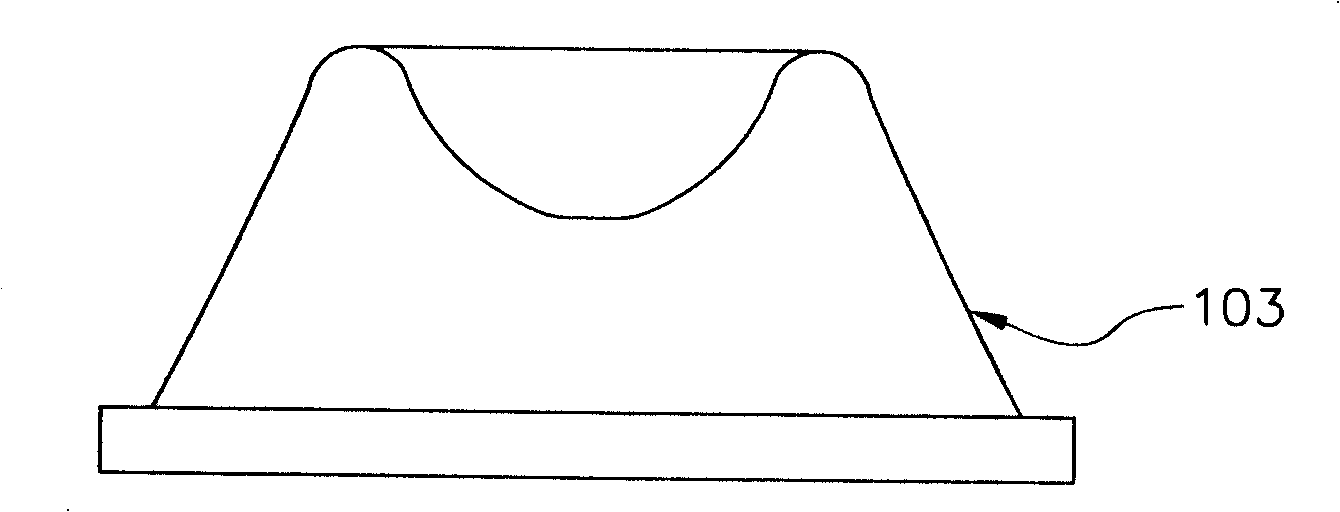

[0037] refer to Figure 6 and Figure 7 The elliptical LED 100 of the first embodiment of the present invention has a power of at least 1 watt (W), and includes a base 110 , a chip body 120 , an LED lens 130 , and two metal terminals 140 .

[0038] The base 110 is an insulator.

[0039] The chip body 120 is a conductor (die), and is mounted on the middle position of the top surface of the base 110 .

[0040] The metal terminal 140 is disposed around the base 110 and is electrically connected to the chip main body 120 .

[0041] Figure 8 It is another side view of the first embodiment.

[0042] refer to Figure 6 , Figure 7 and Figure 8 , the LED lens 130 is covered on the chip main body 120 . The LED lens 130 has a transmissive portion 131 and a horizontal flange 132 disposed around the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com