Belt for a set of belt drums in a two-drum winder, and a two drum winder

A double-drum roll paper and belt-reel technology, which is applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problem of uneven thickness, and achieve low thickness change rate, small stretch change and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

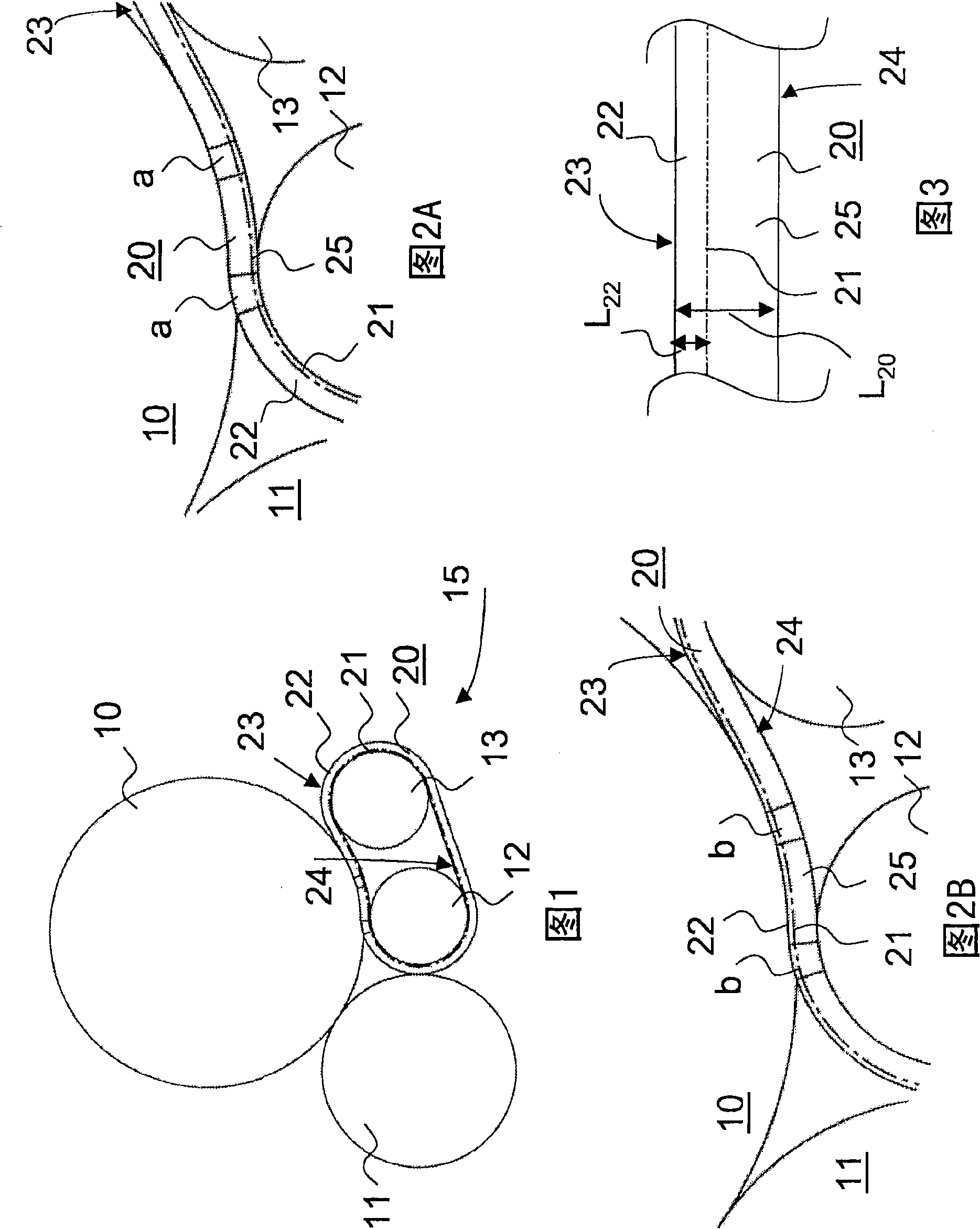

[0021] In the following figures, parts corresponding to one another are identified with the same reference numerals, and parts according to the prior art are primed.

[0022] As shown in Figure 1, a double-drum reel, as is known in the art, comprises support drums 11', 15', a rear support drum 11' and a front support drum 15', shown in this figure In an embodiment, the front support drum 15' is formed by a set of belt pulleys comprising two guide rollers 12', 13' and a belt loop 20' arranged around said two guide rollers. On the double-drum reel, a roll of fibrous web, for example a roll of paper or cardboard, is wound up supported by a rear support drum 11' and the set of belt pulleys 15'.

[0023] As shown in FIG. 2A, when the belt 20' is bent during the winding process of the fiber web, since the bending occurs in the contact area of the belt 20' and the fiber web roll 10' during the winding process, the outer layer of the belt 20' The length of the belt portion a' of 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com