Dissepiment filter plate for filter press

A membrane filter plate, filter press technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of high manufacturing cost, weakened core plate strength, high reject rate, etc., and achieve high service life and high pressing pressure High, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

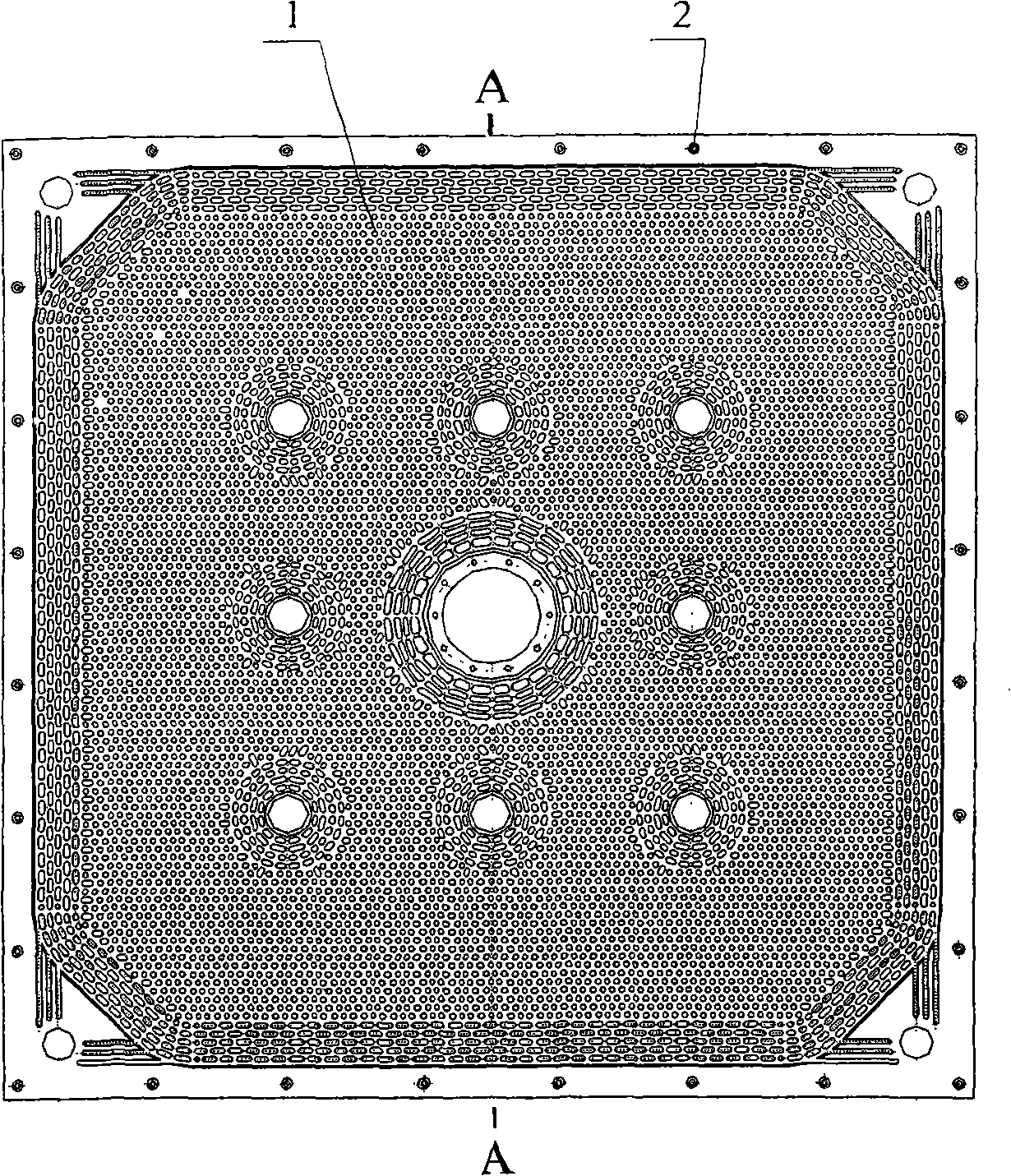

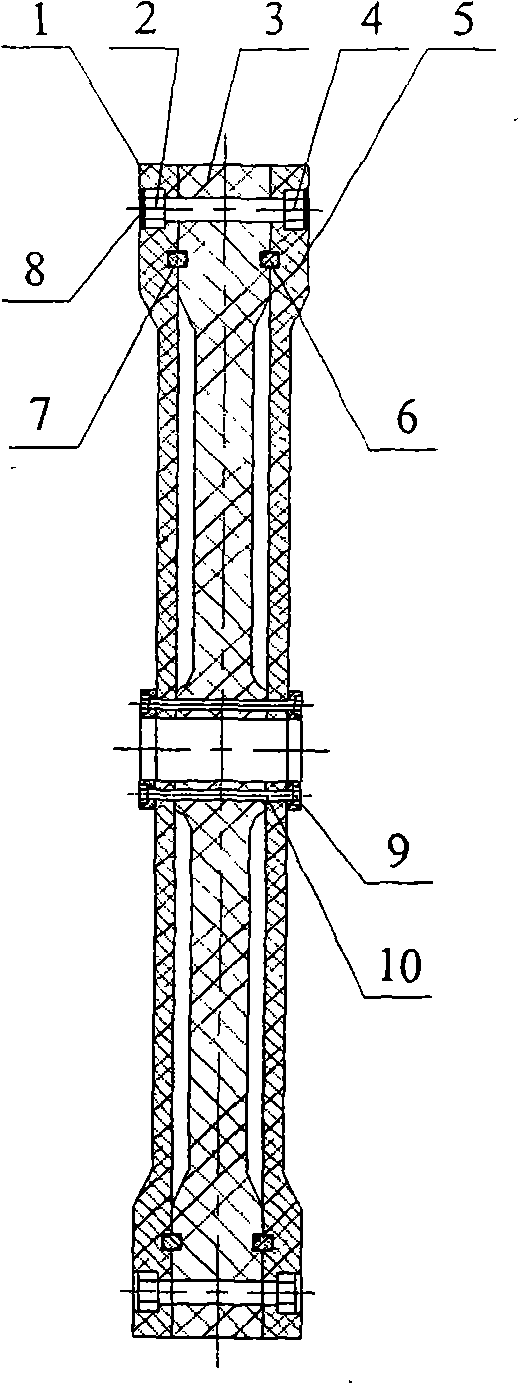

[0014] Such as figure 1 , figure 2 As shown, the present invention includes a diaphragm sheet 1 and a core plate 3 . The two sides of the core plate 3 are respectively equipped with pressure-resistant diaphragms 5, and the surroundings are connected by screws 2 and nuts 4. Elastic sealing elements 6 and 7 are respectively installed between the diaphragm 5 and the core plate 3 to ensure the tightness of the pressing fluid. seal; figure 2 Middle 9 is diaphragm clamp, fixes with screw 10.

[0015] The end faces of the screws 2 and nuts 4 are blocked with plastic covers or plastic welding 8.

[0016] The material of the diaphragm 1 is polypropylene, polypropylene elastomer, hard rubber, polyethylene or fluoroplastic.

[0017] The material of the core plate is metal, polypropylene, polyethylene or fluoroplastic.

[0018] The size of the membrane filter plate is 250-3000 mm, the number of fixing screws 2 and nuts 4 is 2-100, and the core plate 3 can be metal or non-metal.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com