Forgeable piece forging shaping method

A technology of forging and forging, which is applied in the field of forging and forming technology, and can solve the problems of large amount of forging deformation and high impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

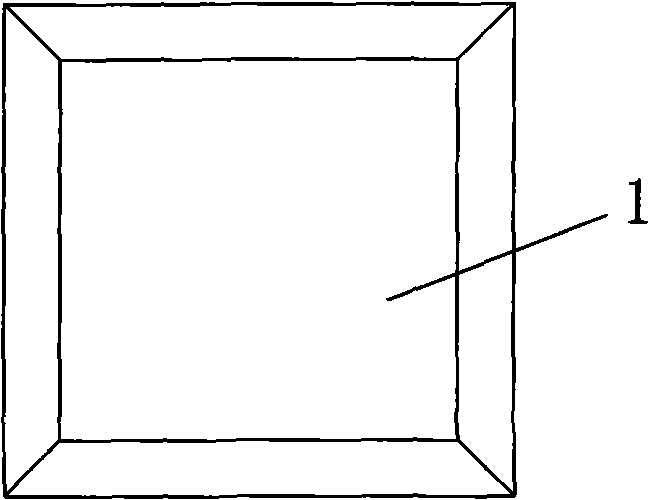

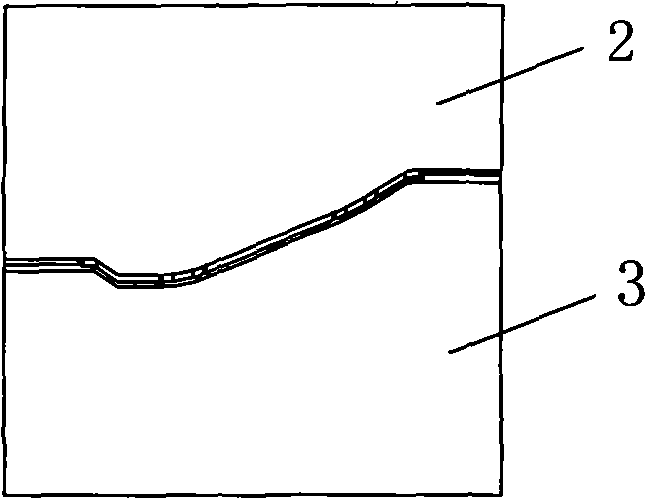

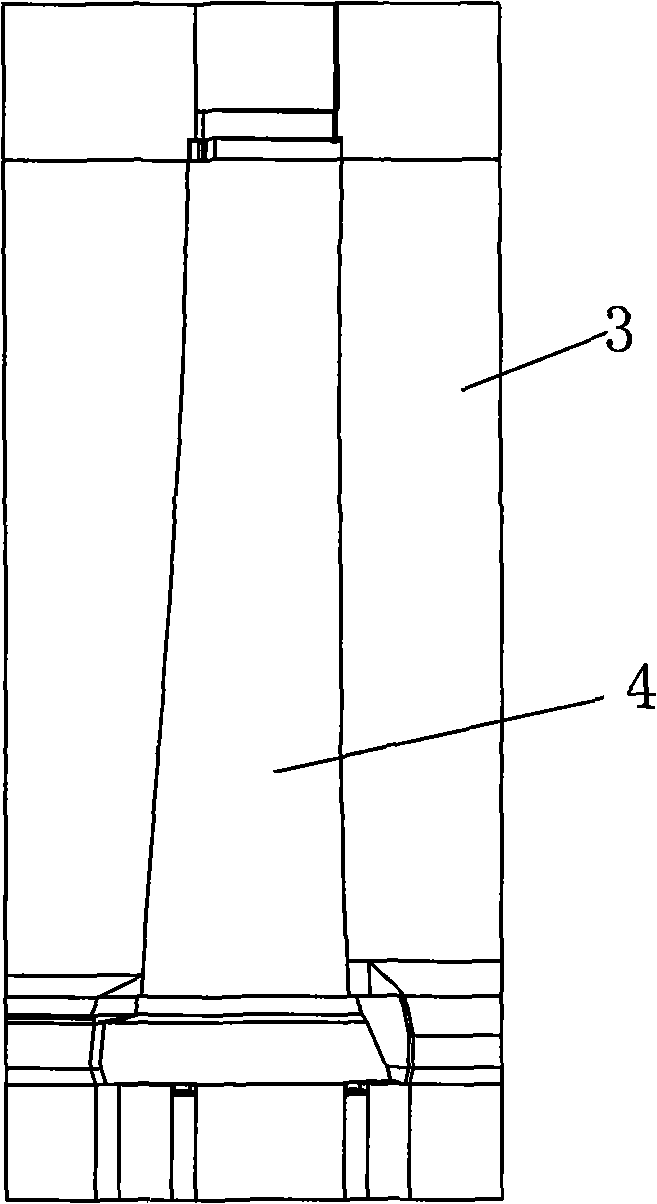

[0014] Combine below figure 1 , figure 2 , image 3 Describe the process of the present invention:

[0015] Put the blade blank 4 into the cavity of the lower mold 3, and then forge it once to fill the larger part of the blade into shape, such as figure 2 Shown; after the first forging, it will be as figure 1 The iron sheet 1 shown covers the part of the blade 4 that does not fill the cavity. The thickness of the iron sheet is 3 mm to 5 mm. The four sides of the iron sheet 1 are chamfered. Heat it to 200 degrees Celsius to 250 degrees Celsius before use, such as image 3 As shown, then forging is performed once. During this forging process, the upper die 2 is in contact with the iron sheet 1, so that the part of the workpiece contacting with the iron sheet 1 is fully formed. After the second forging, the part of the blade profile pad iron sheet There is a slant transitional drop with other parts. The iron sheet 1 is removed for the third forging. This forging has not touched t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com