Flange for connecting conveyer pipe

A technology of conveying pipes and flanges, which is applied in the field of accessories connecting conveying pipes, can solve the problems of inconvenient disassembly, high precision requirements, and difficult inspection of welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

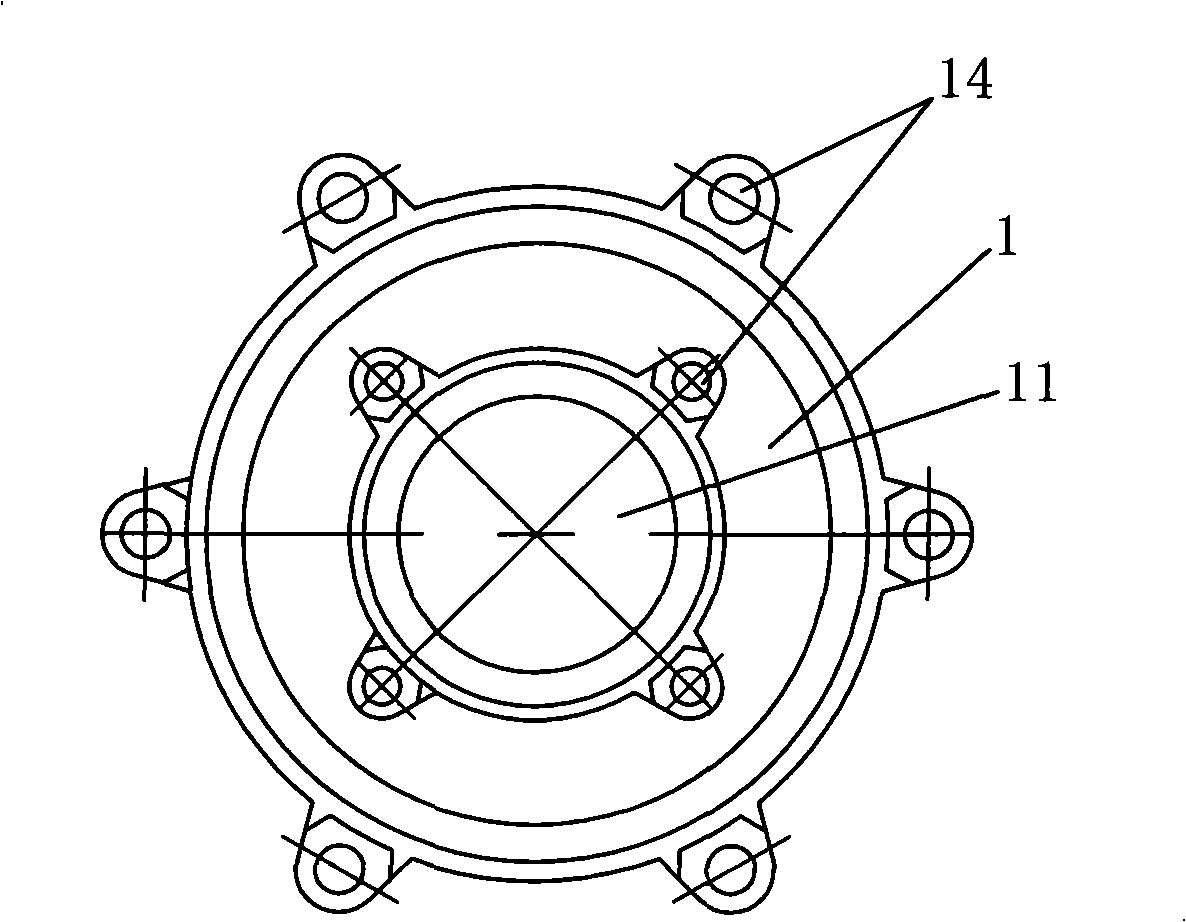

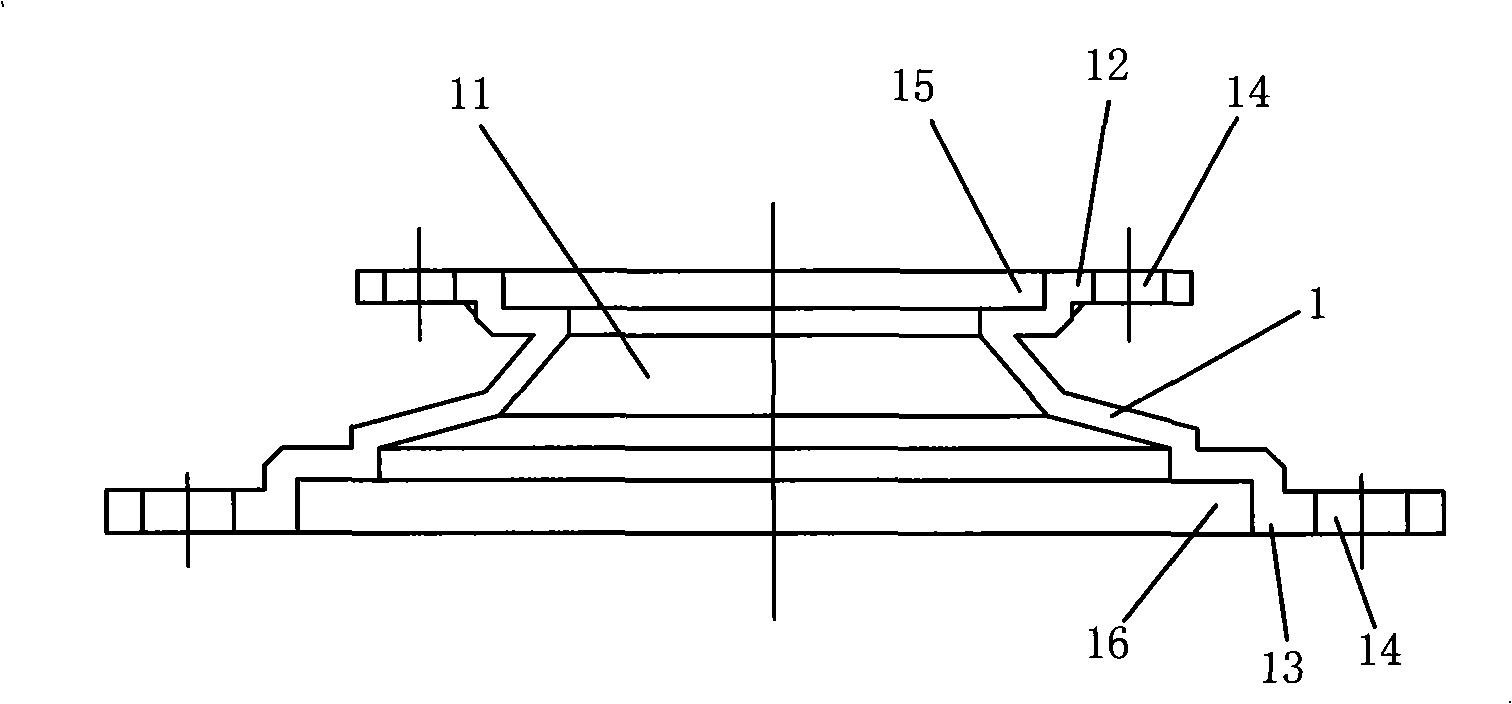

[0017] see figure 1 with 2 , the present invention is provided with body 1, and body is provided with center through hole 11, and both ends of body 1 are flanges, and 2 flanges 12 and 13 are respectively provided with 4 bolt holes 14 and 6 bolt holes 14. The central through hole 11 is a central through hole with tapering diameter. The two flanges 12 and 13 are respectively provided with grooves 15 and 16 to form double concave flanges. The axes of the grooves 15 and 16 coincide with the axis of the central through hole 11 . The central through hole 11 is a central through hole with tapering diameter.

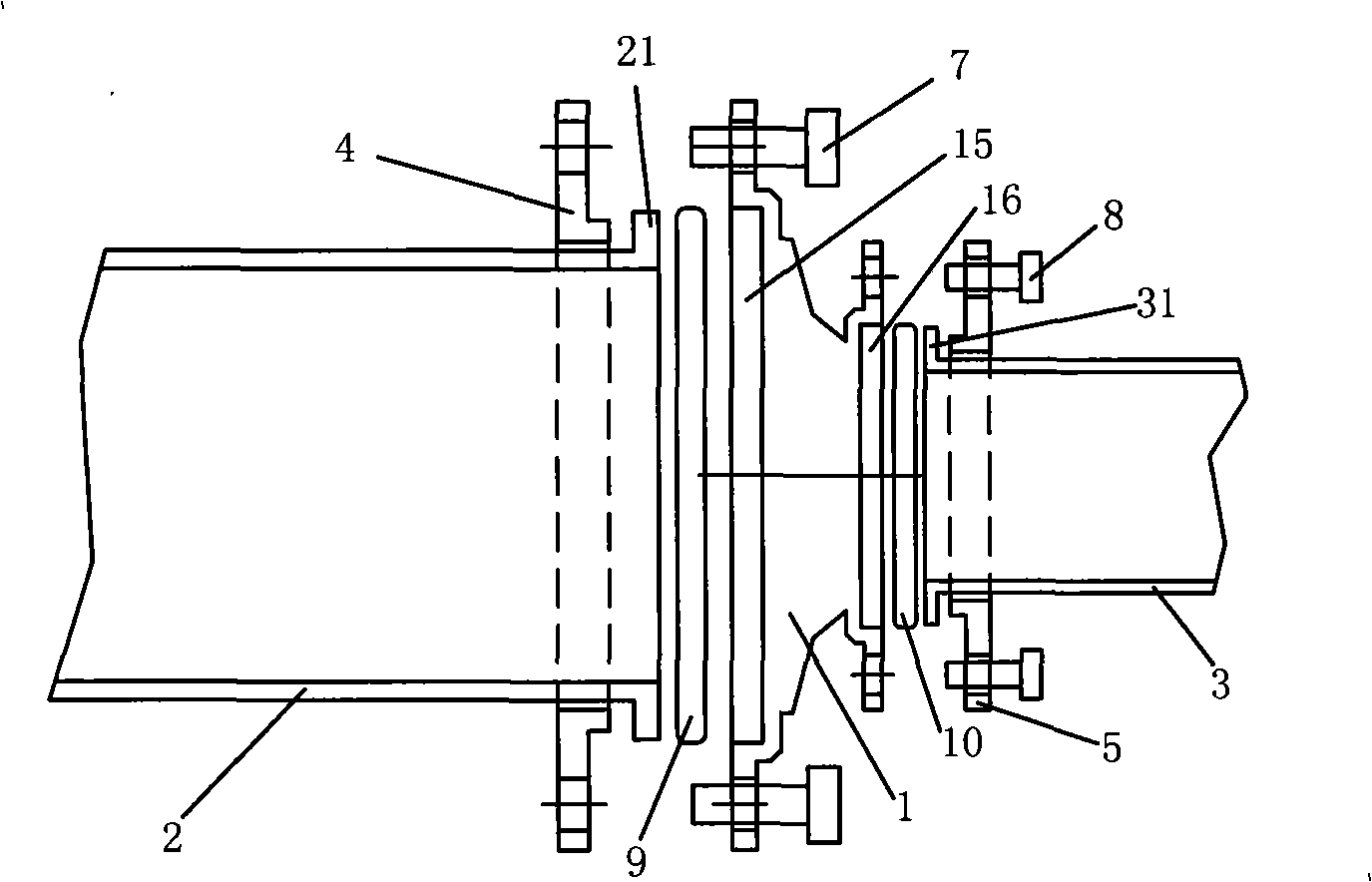

[0018] see image 3 , the ports of the two conveying pipes (straight-through pipes) 2 and 3 to be connected are flanged structures, and the ports of the conveying pipes 2 and 3 are provided with convex flange sleeves 4 and 5 respectively. When connecting, the flange sleeves 4 and 5 respectively press the port flanges 21 and 31 of the two conveying pipes 2 and 3 into the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com