Mine slurry grade on-line detection method

A detection method and grade technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as difficulty in accurately measuring the actual grade of ore pulp, increased production costs of manufacturers, and inability to meet modern production requirements. Guaranteed product quality, high work efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

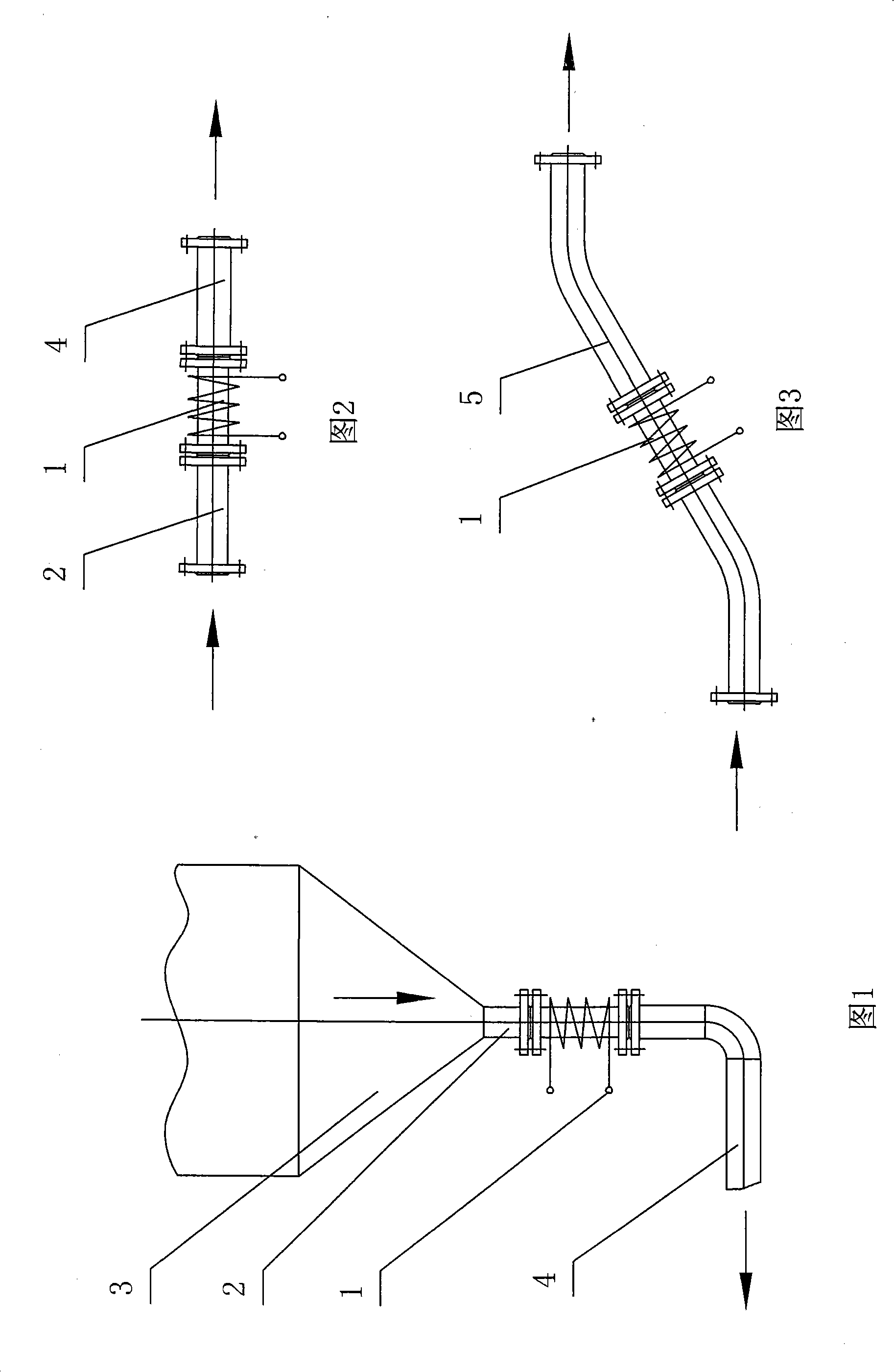

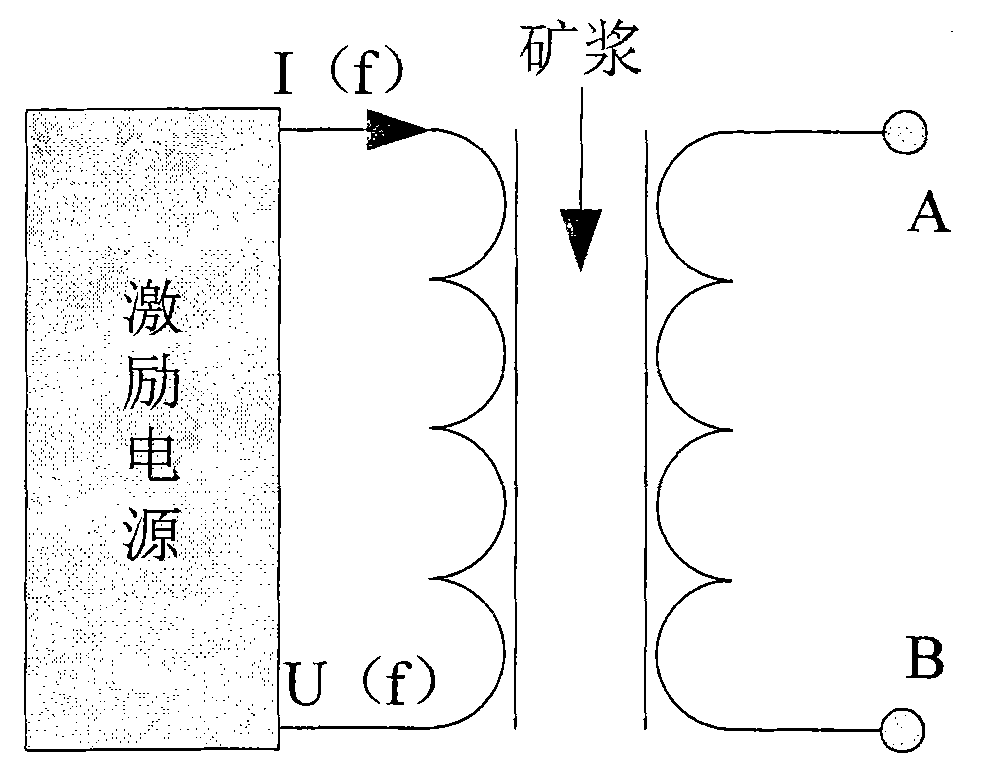

[0025] The on-line detection device for pulp grade provided by the present invention comprises a pipeline 2 for transporting the pulp, the upper end of which is connected with the discharge port at the bottom of the pulp container 3, the upper part of the pulp container 3 is an opening, and the pulp enters the container 3 through the opening, and then The outlet at the bottom of the container enters the pipeline 2, wherein the outer wall of the pipeline 2 is provided with an inductance coil 4, and the lower end of the pipeline 2 is connected with the subsequent slurry delivery pipe 4, as shown in Fig. 1 .

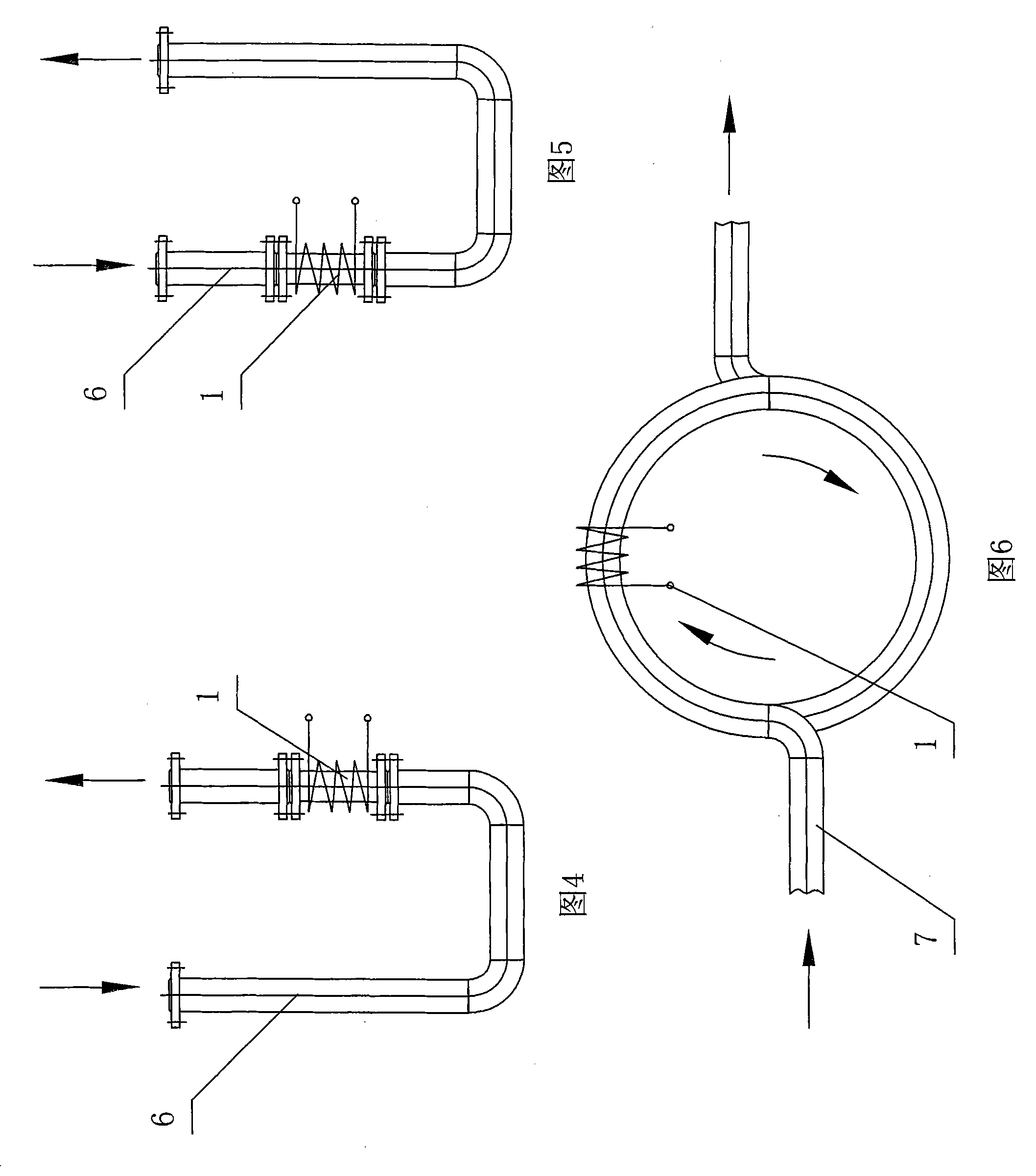

[0026] The on-line detection device for pulp grade provided by the present invention includes horizontal pipelines 2 and 4 for conveying slurry, wherein a pipe section is arranged through a flange betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com