Novel asymmetric synthesis of (S)-(+)-3-(aminomethyl)-5-methylhexanoic acid

A carbamoyl and methyl technology, applied in the field of -pregabalin and -pregabalin intermediates, synthesis of -3--5-methylhexanoic acid, can solve the problem of product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

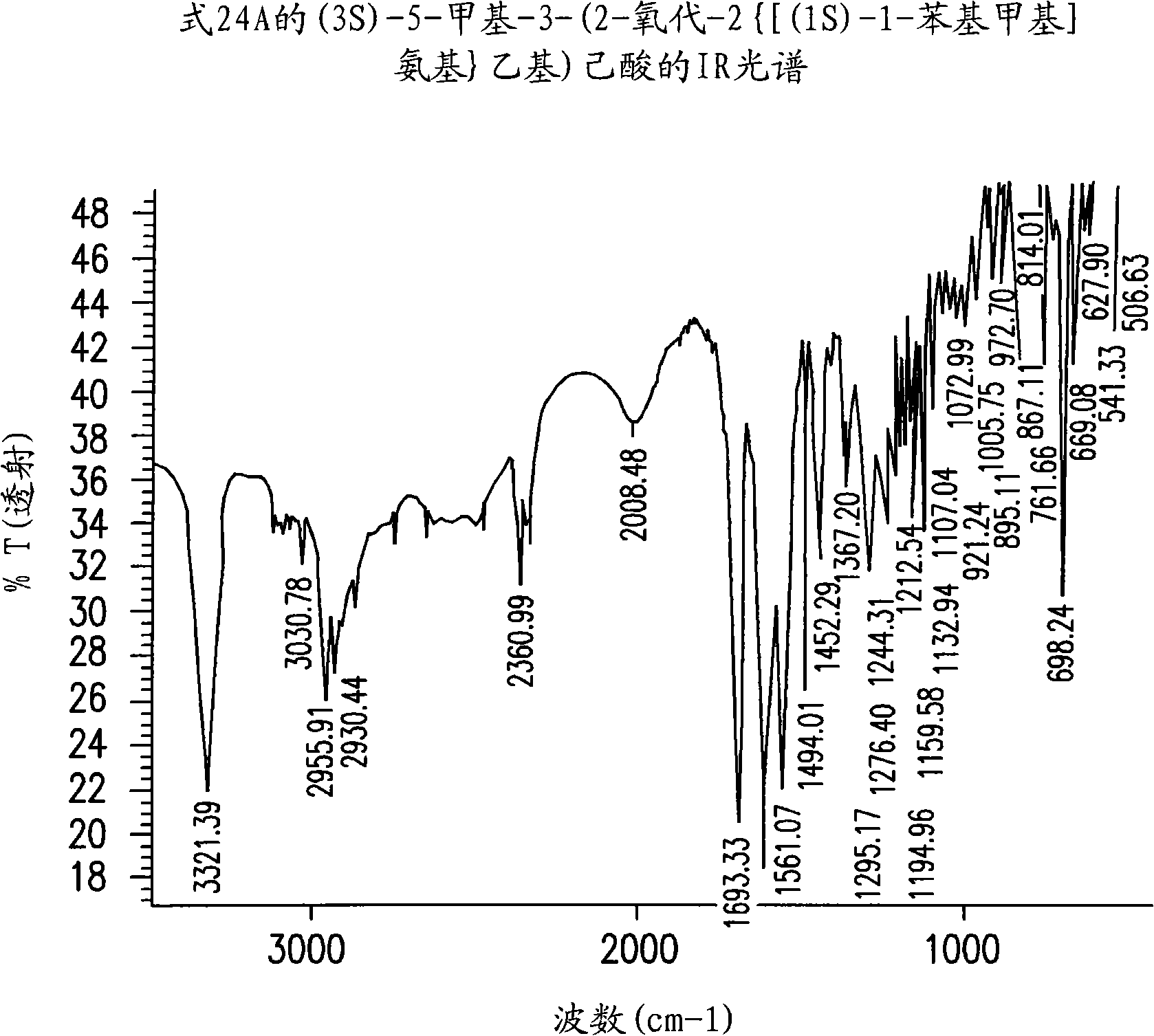

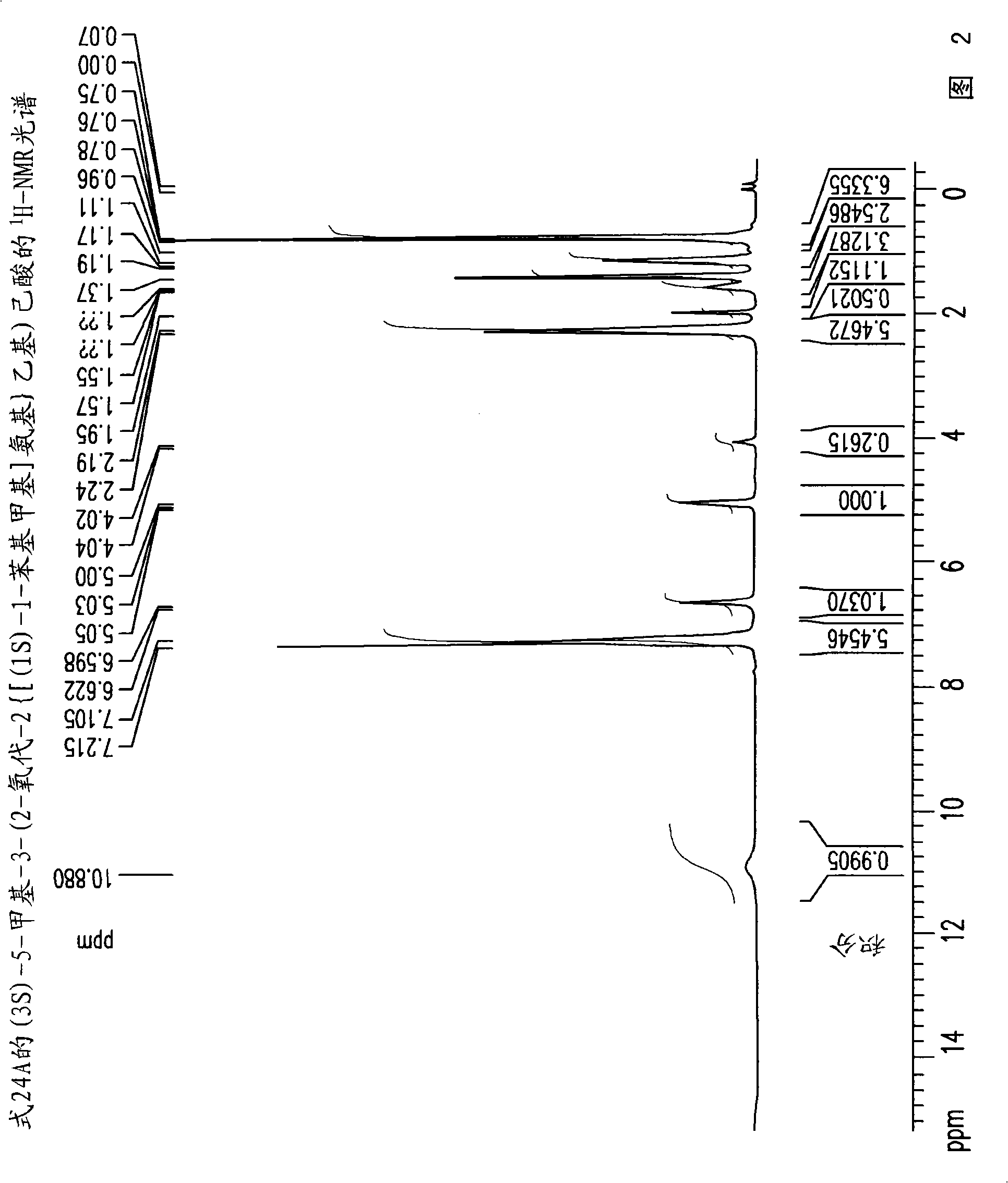

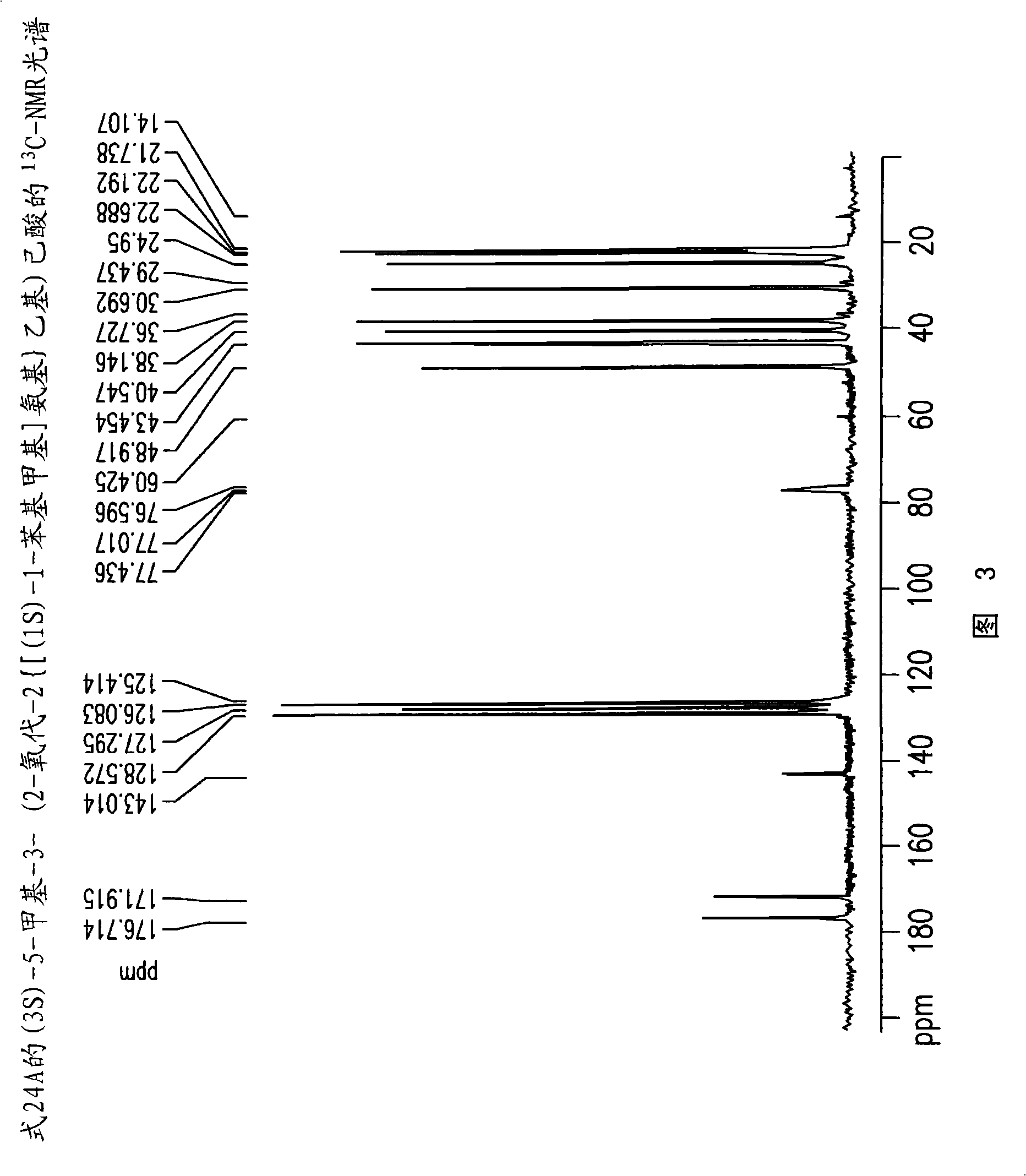

[0267] Example 1: (3S)-5-methyl-3-(2-oxo-2{[(1S)-1-phenylethyl]amino}ethyl)hexanoylation Preparation of compound (24)

[0268] Toluene (400ml), (S)-(-)-phenethylamine (142.35g, 1.1764mol) and 4-dimethyl Aminopyridine (0.7176 g, 0.0059 mol). The mixture was cooled to a temperature of -10°C to -15°C, followed by the addition of a solution of 3-isobutylglutaric anhydride (100 g, 0.59 mol) in toluene (100 ml) over a period of 45-60 minutes, and at -10°C Stir for an additional 1.5-2 hours to a temperature of -15°C. The mixture was then extracted with 10% aqueous NaOH (500ml) and the aqueous phase was washed with toluene (1 x 250ml). The pH of the aqueous phase was adjusted to 2-2.5 by adding aqueous hydrochloric acid (1-12N). The aqueous phase was further extracted with toluene (1 x 800ml) at a temperature of 70-80°C. The toluene layer was washed with 10% sodium chloride solution (700ml) at 70-80°C, followed by crystallization to give 125g (73.0% yield) of (3S)-5-methyl-3-(...

Embodiment 2

[0269] Example 2: (3S)-5-methyl-3-(2-oxo-2{[(1S)-1-phenylethyl]amino}ethyl)hexanoylation Preparation of compound (24)

[0270] Toluene (400ml), (S)-(-)-phenylethylamine (38.59g, 0.0.319 moles) and 4-bis Methylaminopyridine (0.358 g, 0.0029 moles). The mixture was cooled to a temperature of -40°C to -50°C, then a solution of 3-isobutylglutaric anhydride (50 g, 0.294 mol) in toluene (100 ml) was added over a period of 45-60 minutes and heated at -40°C Stir for an additional 1.5-2 hours to a temperature of -50°C. The mixture was then extracted with 3.5-4.0% aqueous NaOH (1000ml), and the aqueous phase was washed with toluene (1 x 250ml). The pH of the aqueous phase was adjusted to 2-2.5 by adding aqueous hydrochloric acid (1-12N). The aqueous phase was further extracted with ethyl acetate (1 x 300ml and 1 x 100ml), then the combined ethyl acetate extracts were dried over anhydrous sodium sulfate, and the solvent was removed to obtain a residue. The residue was crystallize...

Embodiment 3

[0271] Example 3: (3S)-5-methyl-3-(2-oxo-2{[(1S)-1-phenylethyl]amino}ethyl)hexanoylation Preparation of compound (24)

[0272] Toluene (1000ml), (S)-(-)-phenylethylamine (266.9g, 2.206mol) and 4-dimethyl Aminopyridine (1.79 g, 0.0147 mol). The mixture was cooled to a temperature of -40°C to -50°C, followed by the addition of a solution of 3-isobutylglutaric anhydride (250 g, 1.471 mol) in toluene (250 ml) over a period of 45-60 minutes, and at -40°C Stir for an additional 1.5-2 hours to a temperature of -50°C. The mixture was then extracted with 3.5-4.0% aqueous NaOH (2350ml), and the aqueous phase was washed with toluene (1 x 250ml). The pH of the aqueous phase was adjusted to 2-2.5 by adding aqueous hydrochloric acid (1-12N). The aqueous phase was further extracted with ethyl acetate (1 x 1250ml and 1 x 500ml), then the combined ethyl acetate extracts were dried over anhydrous sodium sulfate, and the solvent was removed to obtain a residue. The residue was crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com