Integration type arm swing support device and assembly method thereof

An assembly method and integrated technology, applied in transportation and packaging, elastic suspension, suspension, etc., can solve the problems of heavy weight, complicated welding process, limited bearing capacity, etc. The effect of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

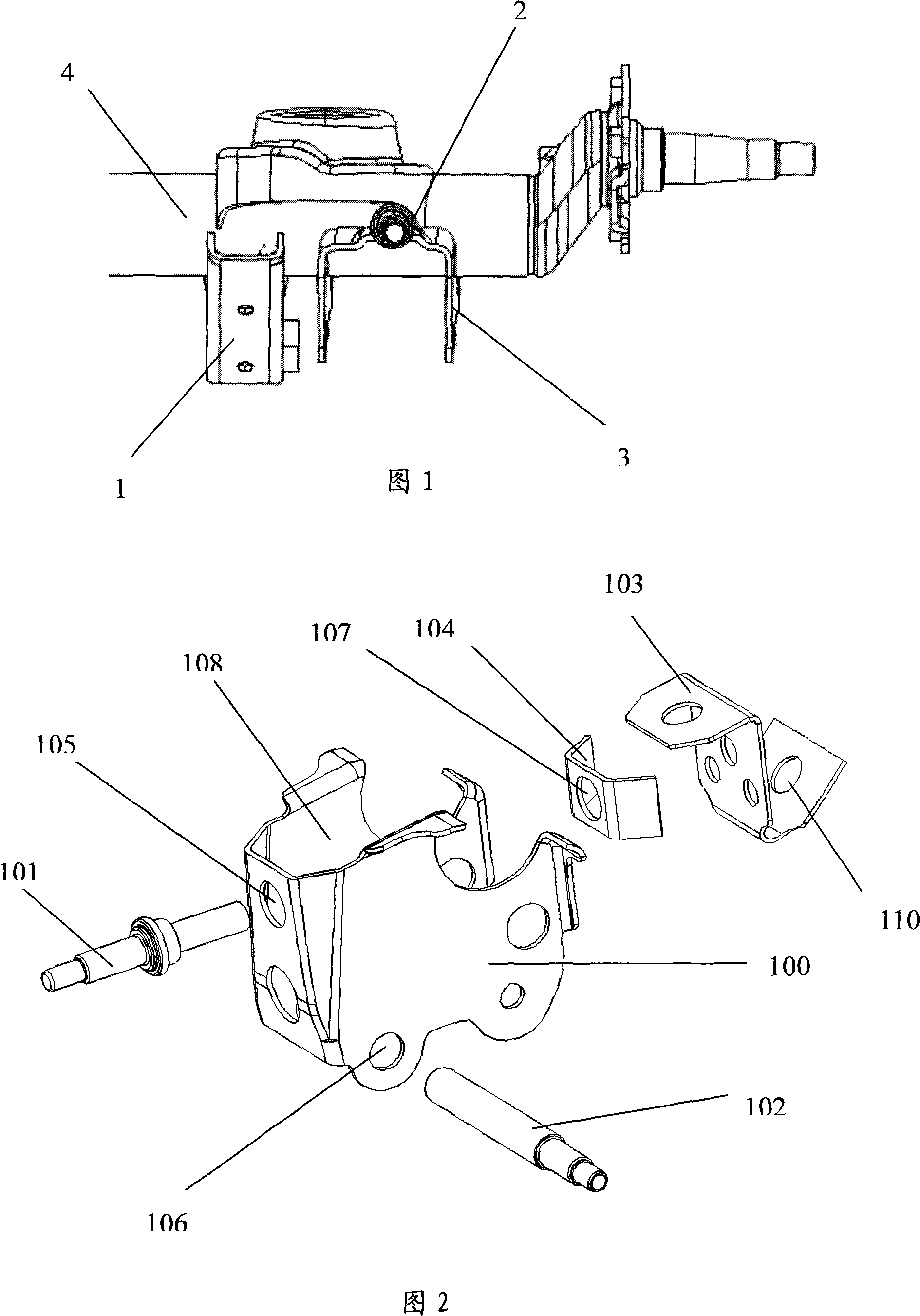

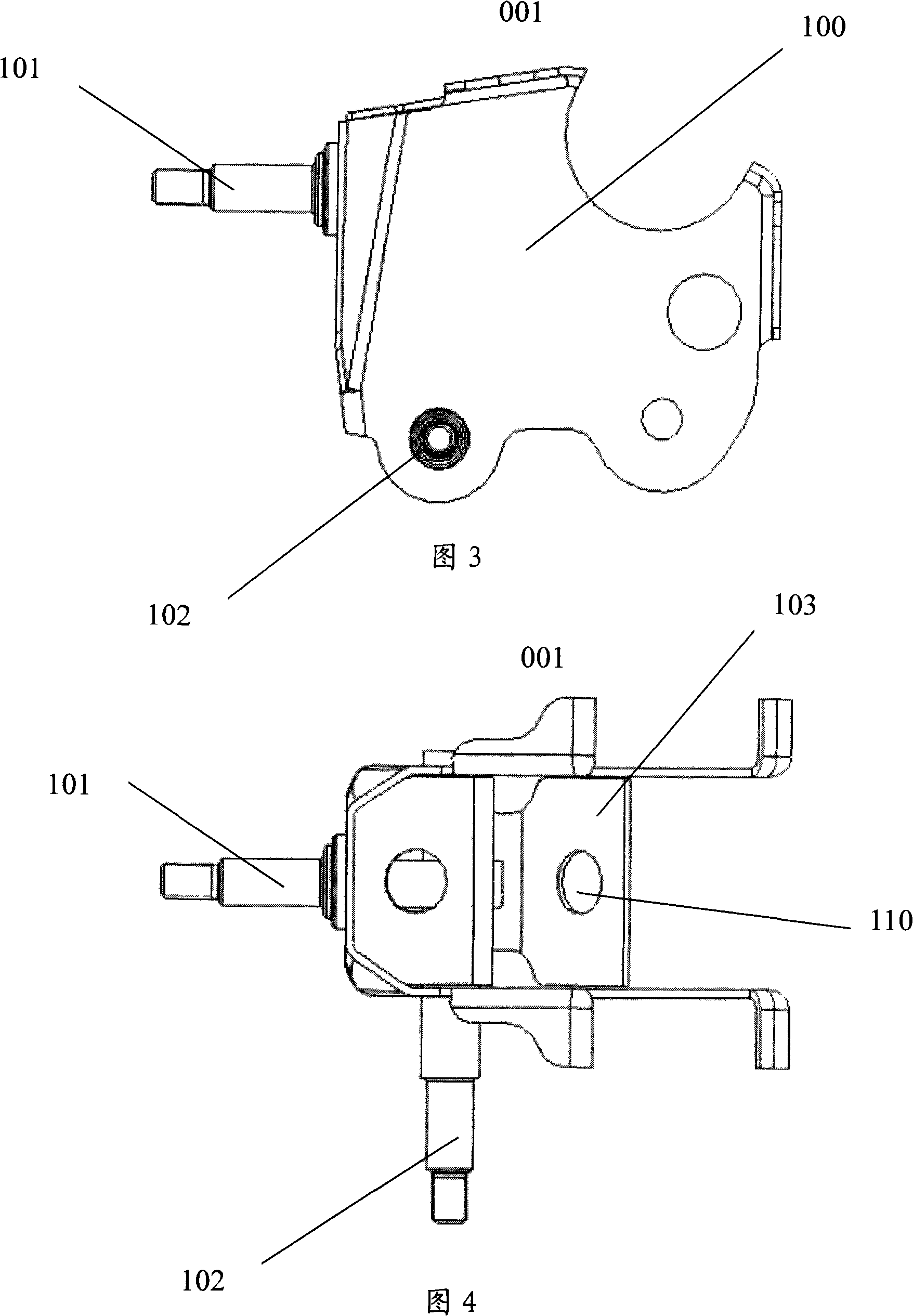

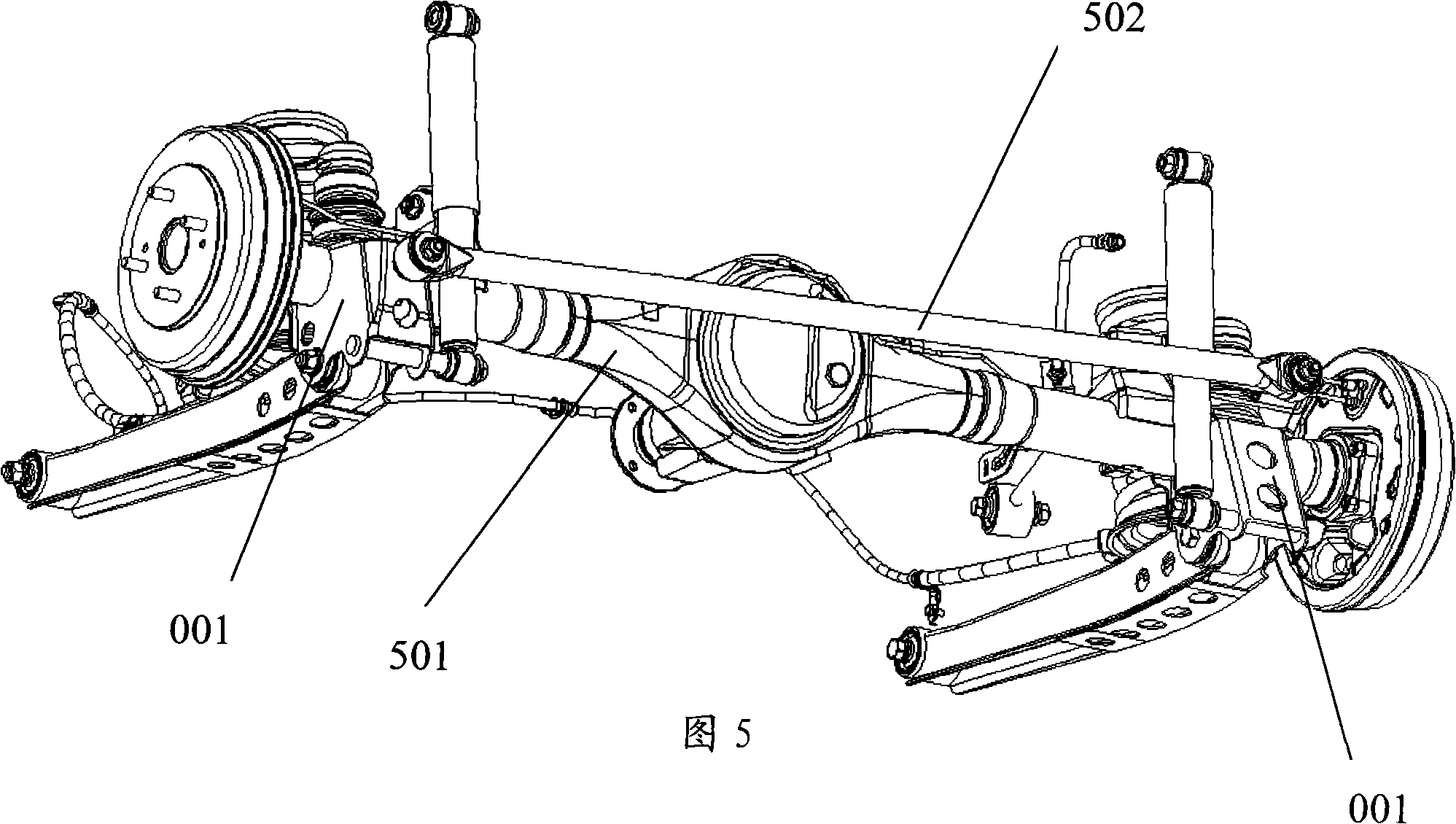

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0019] Please refer to Figure 2, an exploded view of the assembly relationship of the components of the integrated swing arm support device and its assembly method of the present invention, as shown in the figure, an integrated swing arm support is provided in the present invention Seat device 001, the integrated swing arm support device 001 includes an integrated swing arm support 100, and the integrated swing arm support 100 is provided with a rear tie rod support pin mounting hole 105, a shock absorber support pin installation hole 106 and rear tie rod support pin bracket installation position 108, the rear tie rod support pin bracket 103 is fixed to the integrated swing arm support 100 through the rear tie rod support pin 101, and the integrated swing arm The support 100 can integrate the rear tie rod support pin 101 , the shock absorber support pin 102 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com