Cycle frame structure of vehicle

A frame structure and vehicle technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems of short deformation zone length and inability to guarantee the effective length of energy absorption, so as to improve energy absorption efficiency and strengthen impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

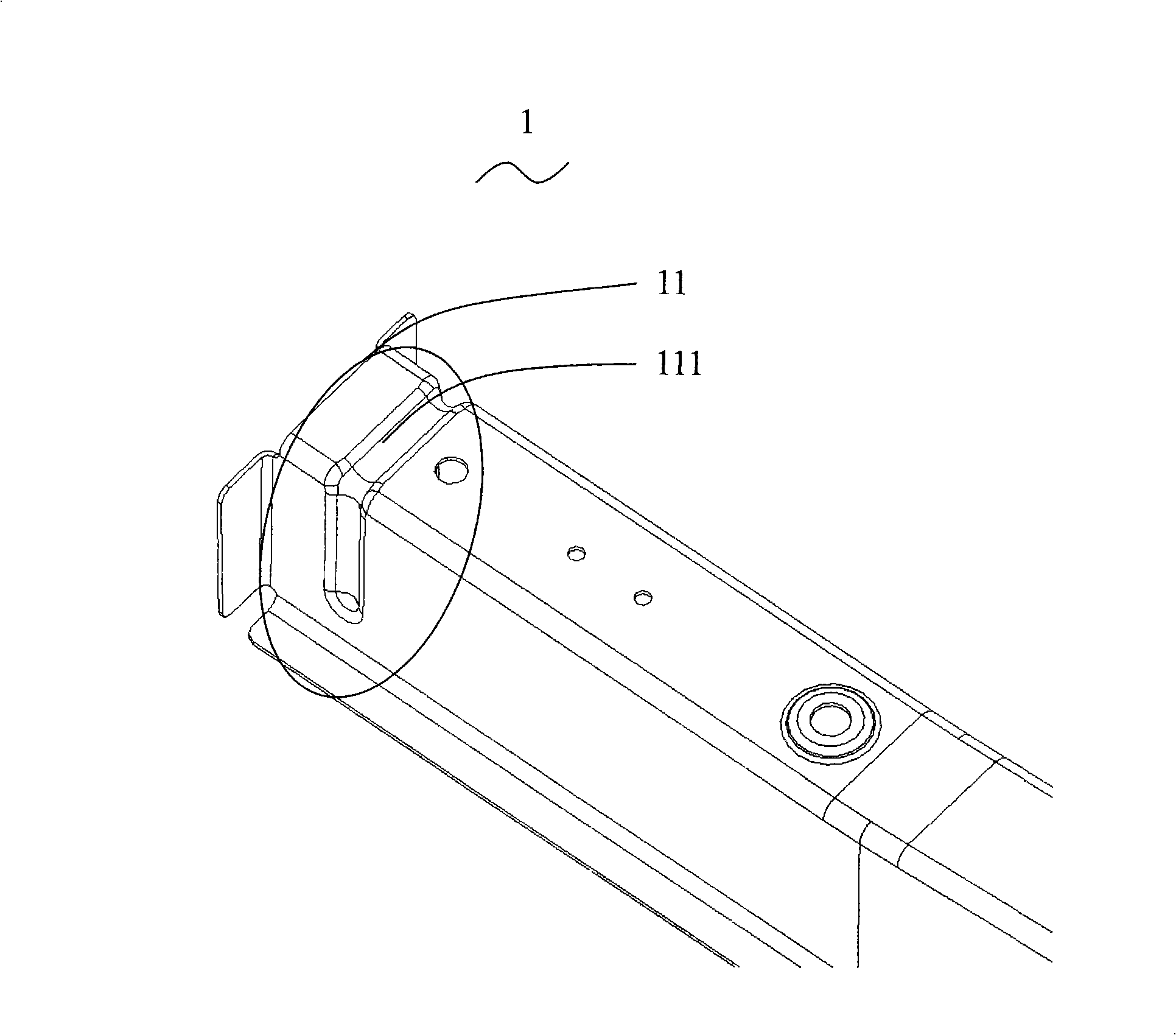

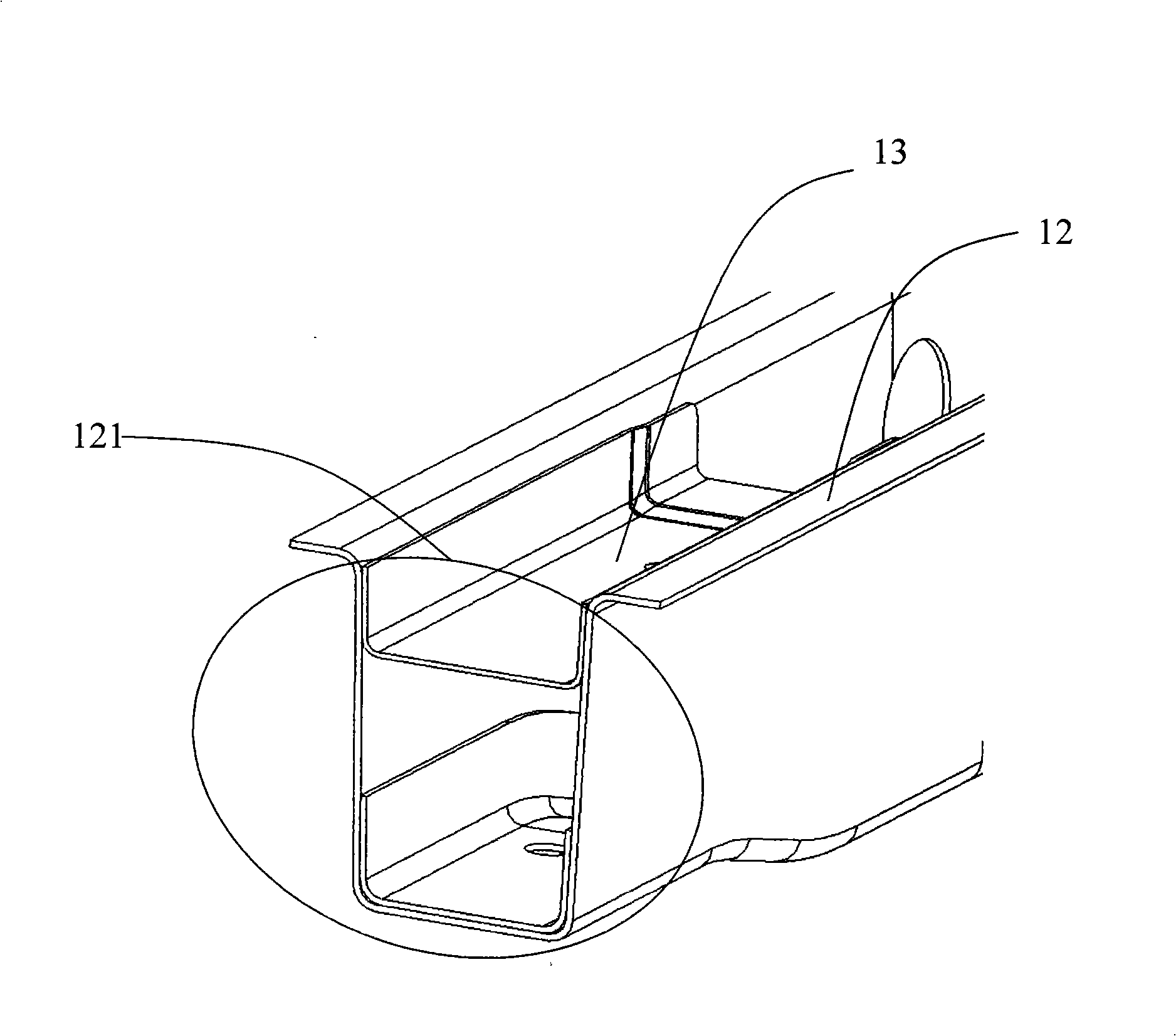

[0018] like figure 1 As shown, a vehicle frame structure includes longitudinal beams 1 arranged on both sides of the vehicle, and a crush deformation induction part 11 is arranged on the front part of the longitudinal beam 1; the crush deformation induction part 11 is a crush deformation induction part The induction groove 111 may also be an induction hole or an induction rib, and is used for weakening treatment when the longitudinal beam undergoes compression collapse in the axial direction. Combined with the reasonable configuration of the material and material thickness of the longitudinal beam, when a collision occurs, the impact energy can be more effectively absorbed, and the possibility of occupant injury is reduced.

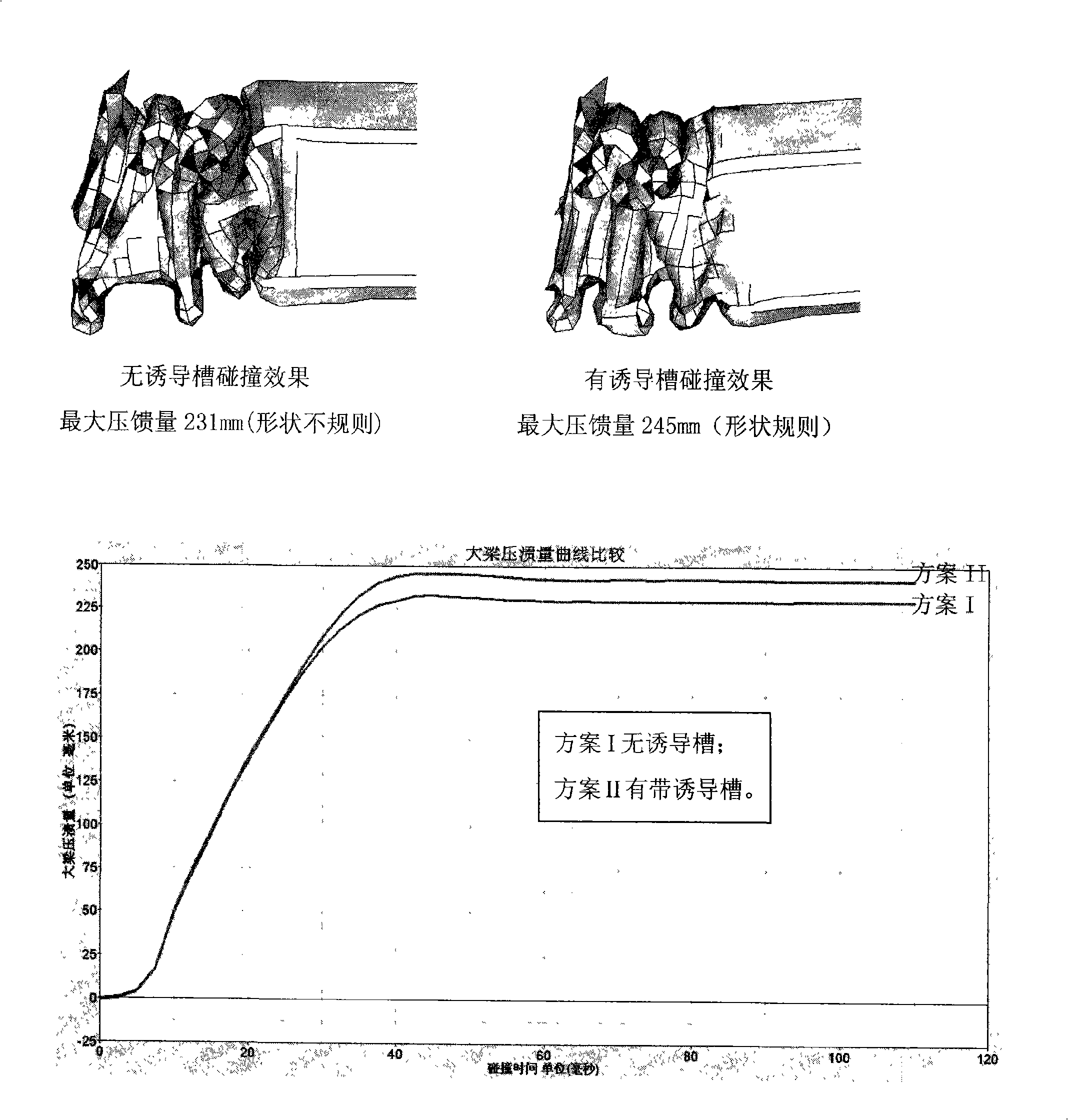

[0019] like figure 2 as shown, figure 2 The upper left is the schematic diagram of the existing collision deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com