Method for treating sludge by microwave enhanced wet-type catalytic oxidation

A wet catalytic oxidation and sludge technology, which is applied in oxidation treatment of sludge, chemical instruments and methods, sludge treatment, etc., can solve the problems of low thermal efficiency, high operating cost, and large influence of contact area on electric heating heat transfer efficiency, etc. , to achieve the effect of high decomposition efficiency, good economic value, and convenient follow-up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

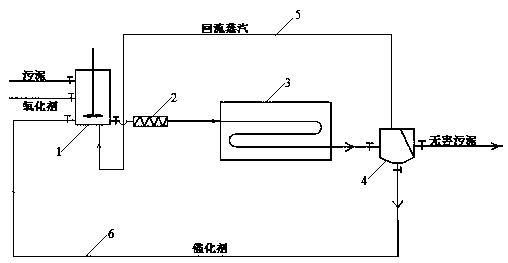

[0028] A method for microwave-enhanced wet catalytic oxidation treatment of sludge, such as figure 1 As shown, the reaction device of the present invention includes a premixer 1, an axial flow pump 2, a microwave reactor 3, and a three-phase separator 4. The premixer 1 is provided with a stirring device, and the premixer 1 passes through an axial The flow pump 2 is connected to the microwave reactor 3, and the axial flow pump 2 introduces the stirred sludge in the premixer 1 into the microwave reactor 3, and the sludge flows in the serpentine tube in the microwave reactor 3 The complete sludge of the reaction is introduced into the three-phase separator 4 for separation to obtain harmless sludge and catalyzer, and the top of the three-phase separator 4 is connected to the bottom of the premixer 1 through the first conduit 5 to guide the reflux steam into the premixer 1; The bottom of the three-phase separator 4 is connected to the pre-mixer 1 through the second conduit 6 to le...

Embodiment 2

[0037] A method for microwave-enhanced wet catalytic oxidation treatment of sludge, such as figure 1 As shown, the reaction device of the present invention includes a premixer 1, an axial flow pump 2, a microwave reactor 3, and a three-phase separator 4. The premixer 1 is provided with a stirring device, and the premixer 1 passes through an axial The flow pump 2 is connected to the microwave reactor 3, and the axial flow pump 2 introduces the stirred sludge in the premixer 1 into the microwave reactor 3, and the sludge flows in the serpentine tube in the microwave reactor 3 The complete sludge of the reaction is introduced into the three-phase separator 4 for separation to obtain harmless sludge and catalyzer, and the top of the three-phase separator 4 is connected to the bottom of the premixer 1 through the first conduit 5 to guide the reflux steam into the premixer 1; The bottom of the three-phase separator 4 is connected to the pre-mixer 1 through the second conduit 6 to le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com