Honeycomb buffering device capable of improving energy absorption efficiency and design method thereof

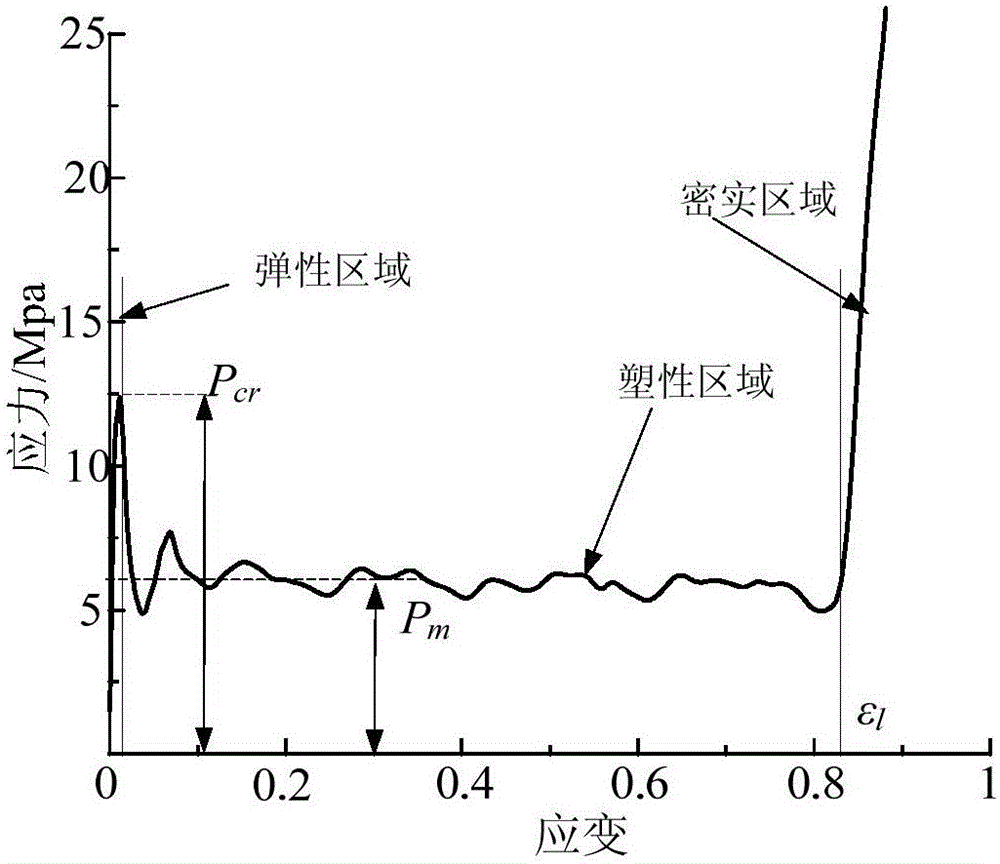

A technology of a honeycomb buffer device and a design method, which are applied in the directions of transportation and packaging, containers to prevent mechanical damage, and vehicle safety arrangements, can solve problems such as difficulty in effectively increasing the average stress and difficulty in effectively reducing the peak stress, and achieve effective energy absorption. The effect of improving efficiency, reducing initial peak stress, and improving energy absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

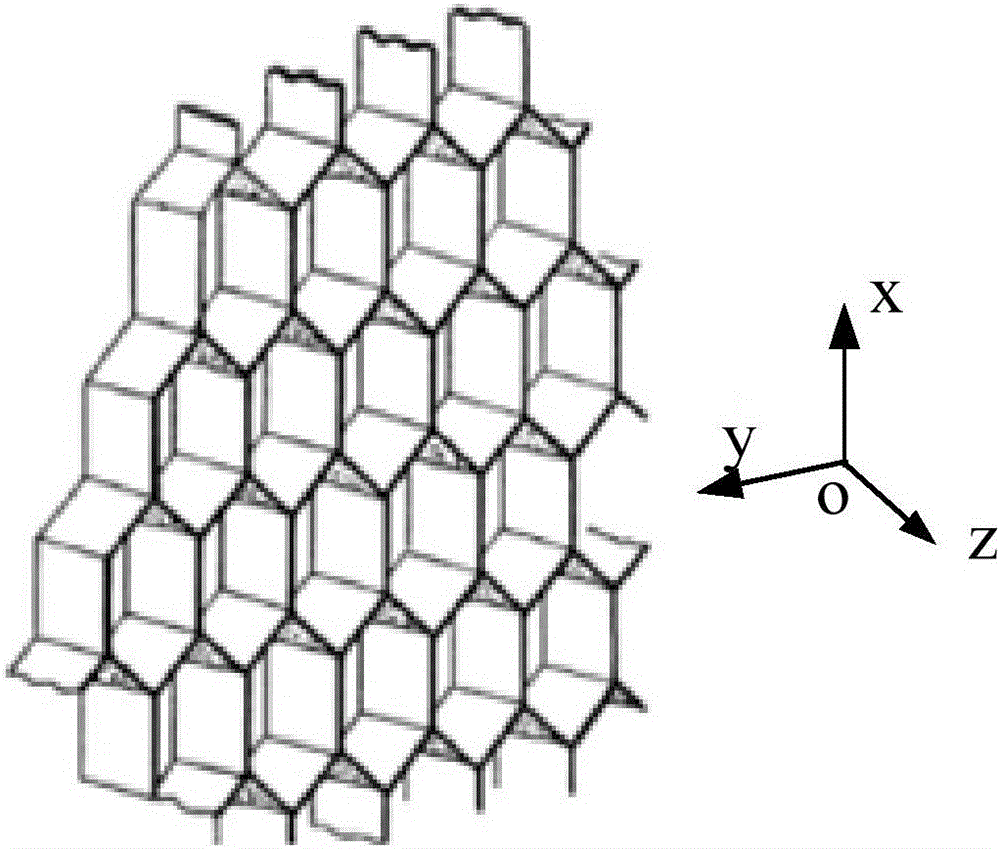

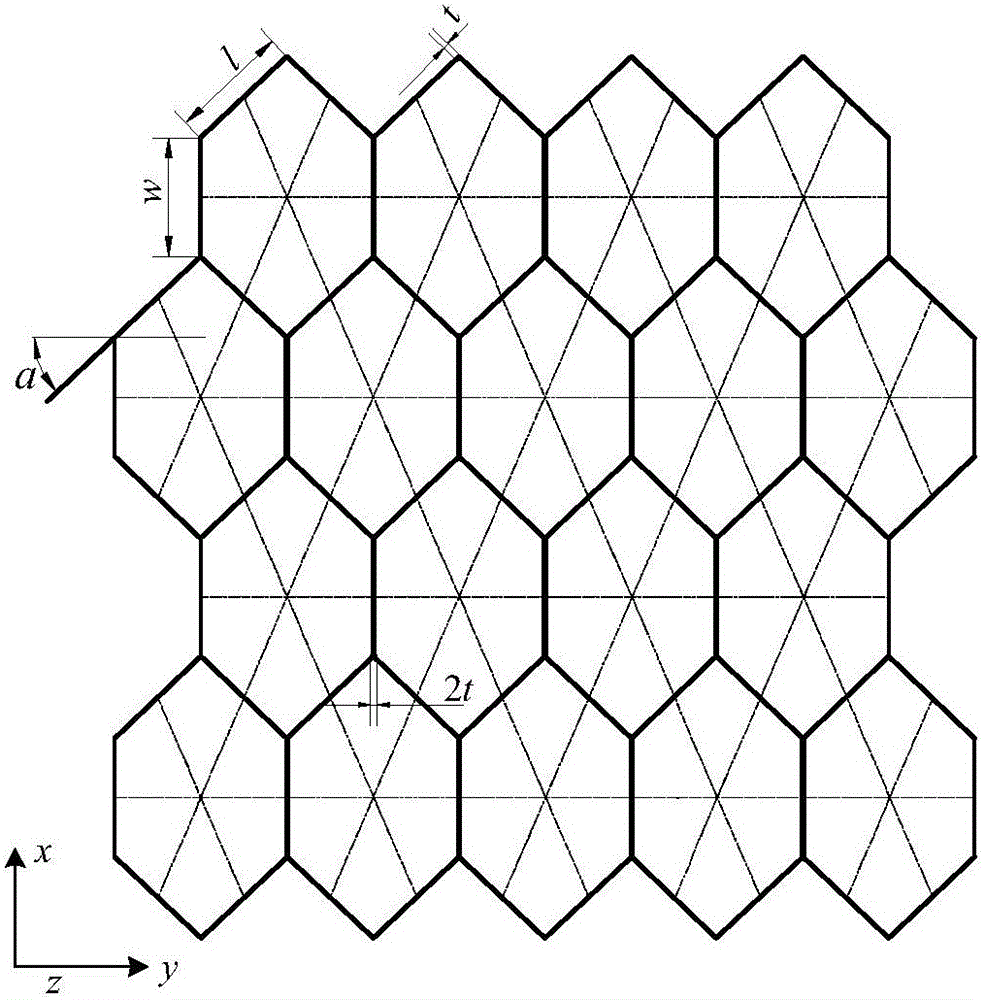

[0042] The side length l of the honeycomb cell is 6mm, the w is 6mm, the thickness t is 0.04mm, and the cell angle α is 30°. Establish coordinate system 1, take the hollow direction of the honeycomb cell in the non-folding area as the Z-axis direction of the coordinate system, and select the direction of any side length of the honeycomb cell on the plane perpendicular to the Z-axis and at the junction of the folding area and the non-folding area as the X-axis direction, Determine the Y-axis direction according to the right-hand rule; fold the honeycomb twice along different planes. After the first fold, the angle between the honeycomb structure in the folded area and the direction of the XZ plane is 18°, and the angle between the direction of the YZ plane is 24°. The height of a folded honeycomb is 0.81mm. The direction of the second folding is opposite to that of the first folding. After the same folding, the angle between the honeycomb structure in the folded area and the di...

Embodiment 2

[0045] The side length l of the honeycomb cell is 6mm, the w is 6mm, the thickness t is 0.04mm, and the cell angle α is 30°. Establish coordinate system 1, take the hollow direction of the honeycomb cell in the non-folding area as the Z-axis direction of the coordinate system, and select the direction of any side length of the honeycomb cell on the plane perpendicular to the Z-axis and at the junction of the folding area and the non-folding area as the X-axis direction, Determine the Y-axis direction according to the right-hand rule; fold the honeycomb twice along different planes. After the first fold, the angle between the honeycomb structure in the folded area and the direction of the XZ plane is 53°, and the angle between the direction of the YZ plane is 65°. The height of a folded honeycomb is 0.81mm. The direction of the second folding is opposite to that of the first folding. After the same folding, the angle between the honeycomb structure in the folded area and the di...

Embodiment 3

[0048] The side length l of the honeycomb cell is 6mm, the w is 6mm, the thickness t is 0.04mm, and the cell angle α is 30°. Establish coordinate system 1, take the hollow direction of the honeycomb cell in the non-folding area as the Z-axis direction of the coordinate system, and select the direction of any side length of the honeycomb cell on the plane perpendicular to the Z-axis and at the junction of the folding area and the non-folding area as the X-axis direction, Determine the Y-axis direction according to the right-hand rule; fold the honeycomb twice along different planes. After the first fold, the angle between the honeycomb structure in the folded area and the direction of the XZ plane is 69°, and the angle between the direction of the YZ plane is 76°. The height of a folded honeycomb is 0.81mm. The direction of the second folding is opposite to that of the first folding. After the same folding, the angle between the honeycomb structure in the folded area and the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle range | aaaaa | aaaaa |

| Peak stress | aaaaa | aaaaa |

| Peak stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com