Centrifugal pump housing having a flat single cover part

A technology for centrifugal pumps and cover parts, applied in the field of centrifugal pumps, can solve problems such as obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

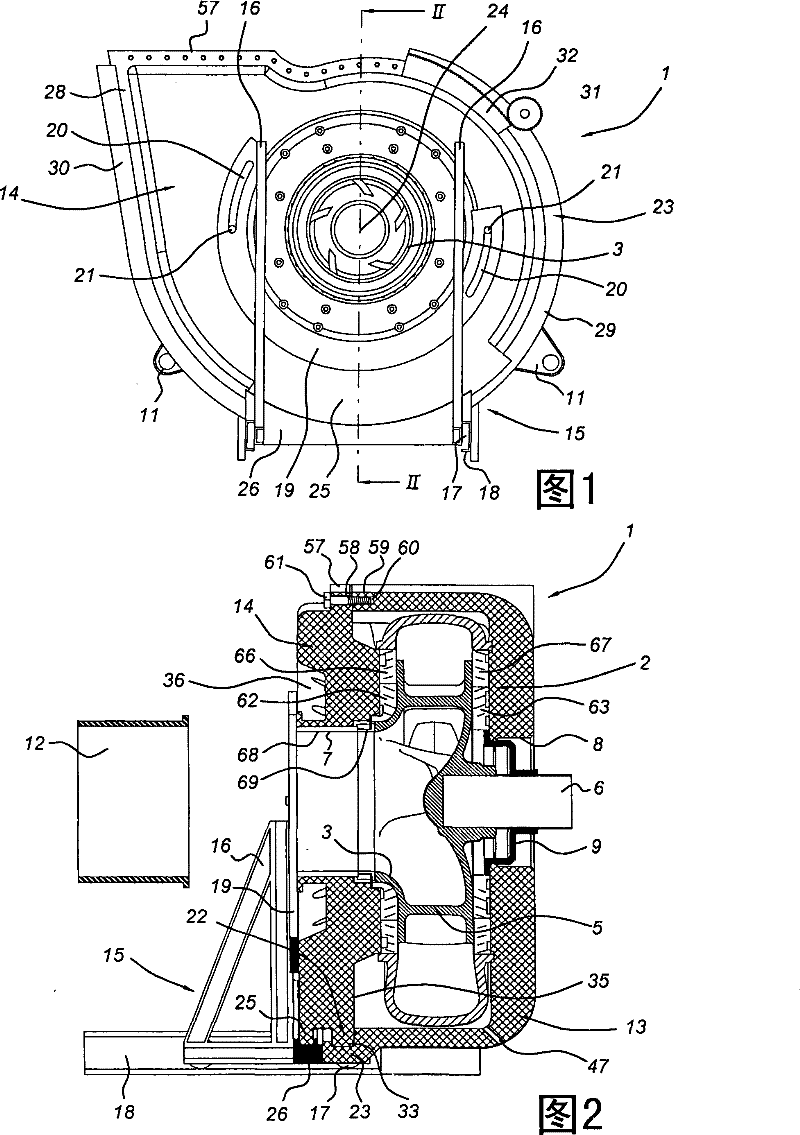

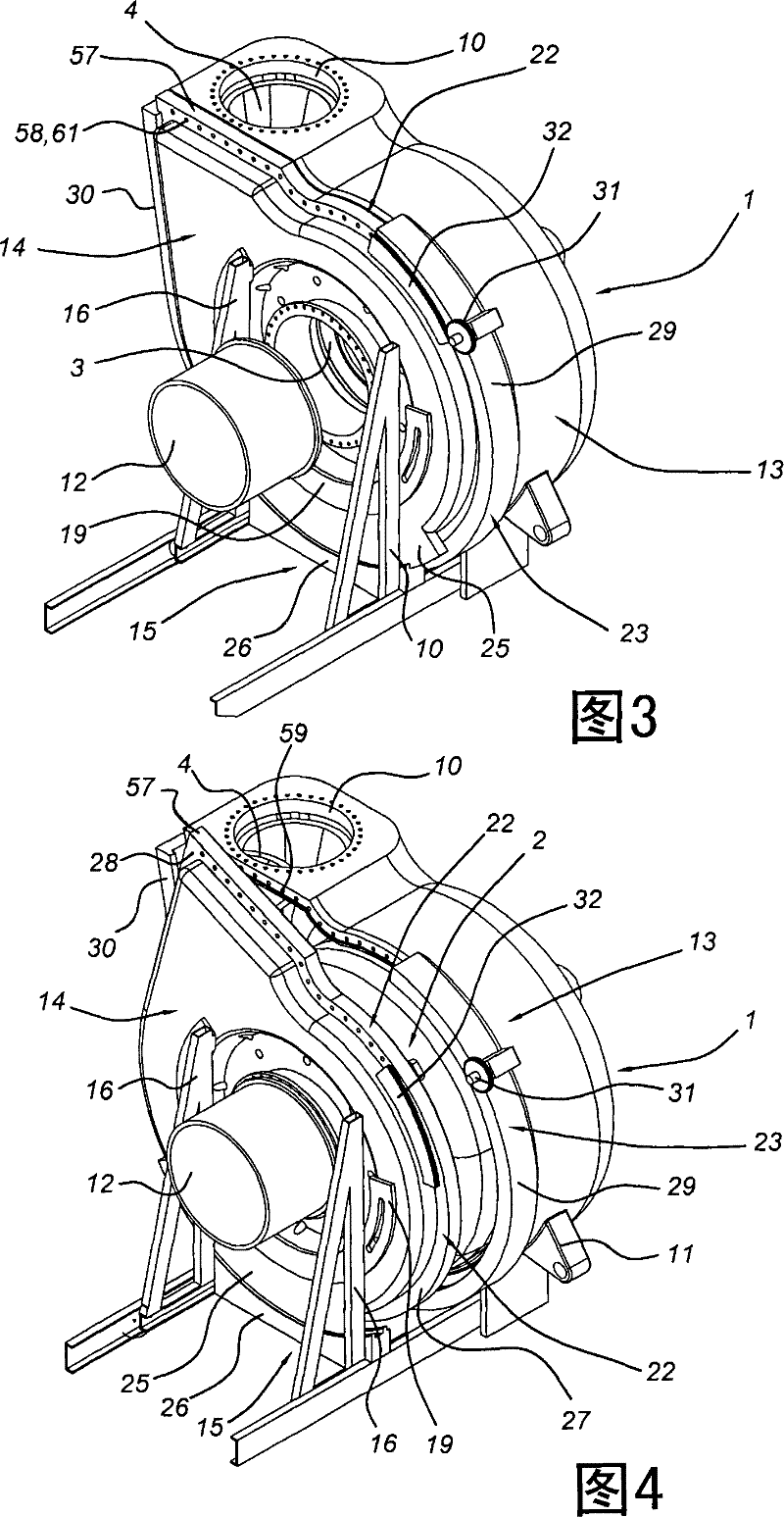

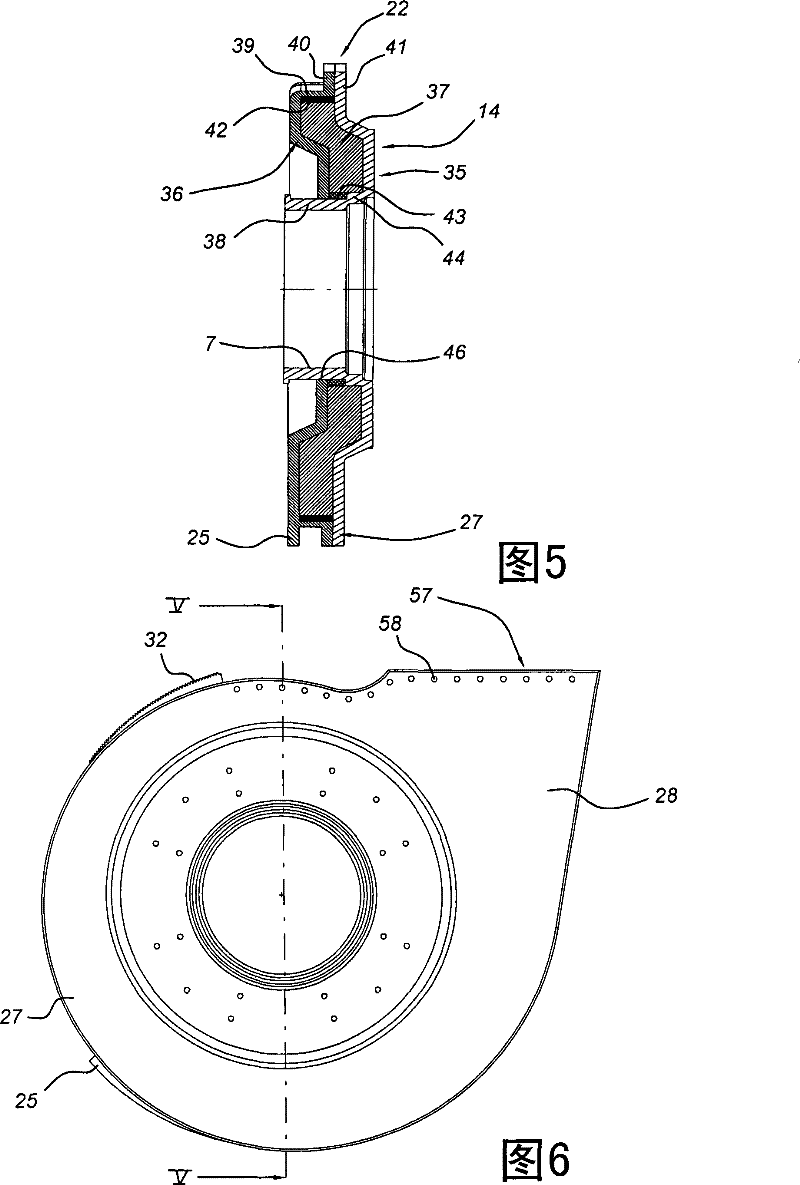

[0031] exist Figure 1-4 The centrifugal pump shown in includes a casing 1, which houses the figure 2 and 4 The inner shell can be seen in 2. The inner shell 2 has a tangentially positioned outlet 4 . The impeller 5 with the suction opening 3 is mounted in the inner housing 2 for rotation about an axis 24 via a drive shaft 6 . Said drive shaft 6 is in turn mounted rotatably in a support (not shown) and connected to a drive motor (not shown).

[0032]Likewise, the casing 1 has a casing inlet opening 7 coaxial with the inlet 3 of the impeller 5 . Due to the overall design of the cover part 14 , the diameter of its inlet opening is smaller than the outer diameter of the impeller 5 . Opposite to the housing inlet opening 7, the housing 1 has a shaft opening 8 through which the drive shaft 6 extends. The drive shaft 6 is sealed relative to the housing 1 by means of the cover 9 . Furthermore, the outer shell 1 has a tangentially positioned outer shell outlet opening 10 which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com