Preparation method of rigid foam flame-retardant polyether polyol for all-water foaming

A technology of all-water foaming and flame-retardant polyether, which is applied in the field of polyurethane synthesis, can solve the problems of weak cohesive force, complex manufacturing process, and poor flame-retardant effect of the thermal insulation system, and achieve good thermal insulation and flame-retardant effects and excellent construction technology. The effect of simplicity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

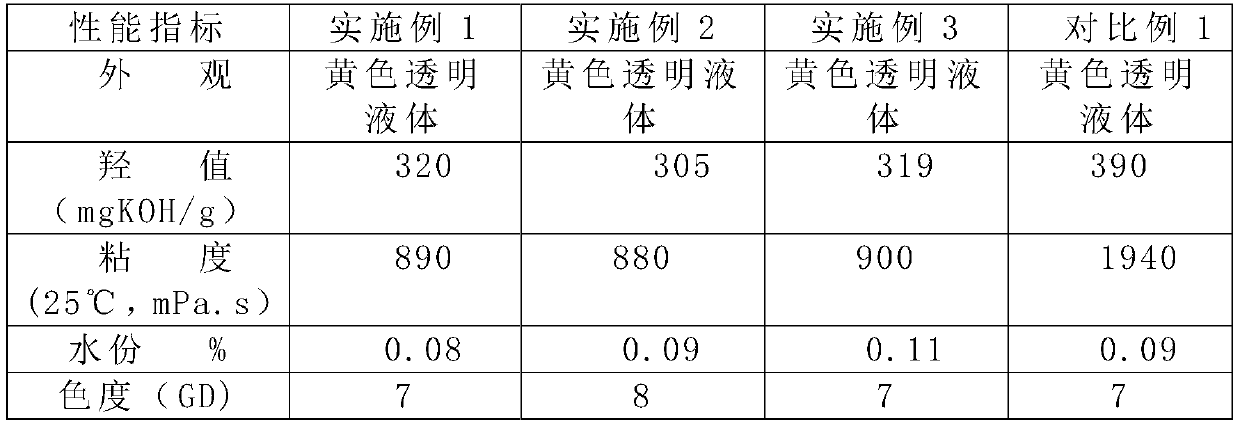

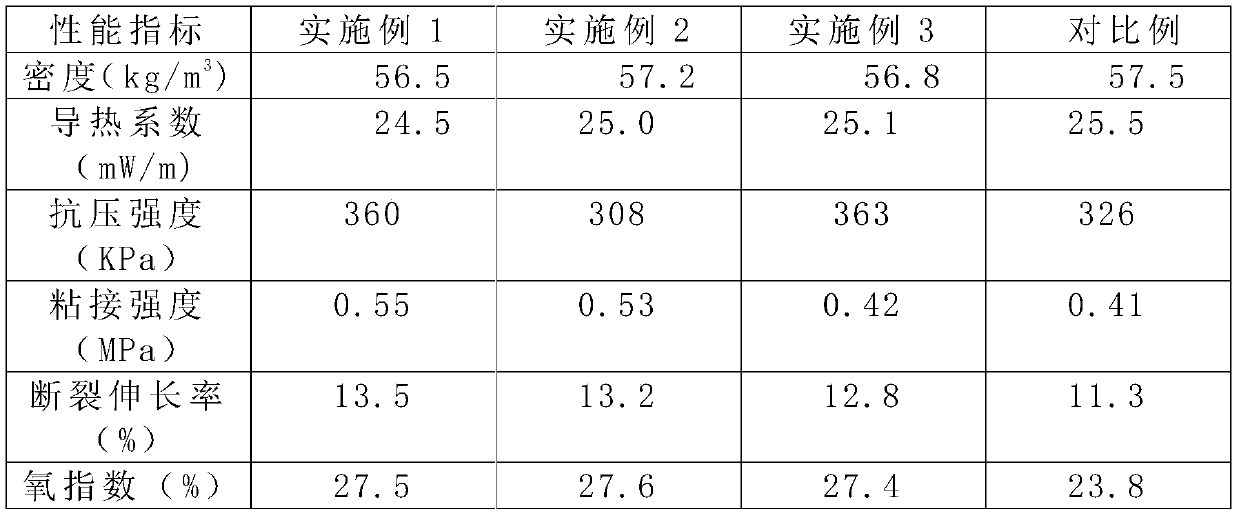

Embodiment 1

[0031] In a 5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 342 g of sucrose, 30 g of bromoneopentyl glycol, and 20 g of diethylene glycol , propylene glycol 30g, phenolic resin 22g, palm oil 225g, potassium hydroxide 7g, nitrogen replacement 3 times, heat up and turn on the vacuum pump, carry out vacuum dehydration at 100-105°C for 3 hours, then cool down to 80°C, and start adding propylene oxide dropwise , by controlling the feeding speed of propylene oxide and the temperature control device, the reaction temperature in the kettle is maintained at 80-110°C, and the pressure is in the range of 0.1-0.4MPa. When the propylene oxide is added to 1200g, then add propylene oxide and ring The mixture of oxyethane is 300g (propylene oxide 180g, ethylene oxide 120g), the temperature is 80-110°C and the pressure inside the kettle is controlled at 0.1-0.4MPa, aft...

Embodiment 2

[0034] In a 5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 342 g of sucrose, 30 g of bromoneopentyl glycol, and 20 g of diethylene glycol , propylene glycol 30g, palm oil 225g, potassium hydroxide 7g, nitrogen replacement 3 times, heat up and turn on the vacuum pump to carry out vacuum dehydration at 100-105°C for 3 hours, then cool down to 80°C, start to drop propylene oxide continuously, through the control ring The feeding speed of propylene oxide and the temperature control device keep the reaction temperature in the kettle at 80-110°C, and the pressure is in the range of 0.1-0.4MPa, until the propylene oxide is added to 1200g, then add the mixture of propylene oxide and ethylene oxide. 300g of the mixture (180g of propylene oxide, 120g of ethylene oxide), the temperature is 80-110°C and the pressure inside the kettle is controlled at 0.1-0.4MPa. A...

Embodiment 3

[0037] In a 5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 342 g of sucrose, 30 g of bromoneopentyl glycol, and 20 g of diethylene glycol , propylene glycol 30g, phenolic resin 22g, palm oil 225g, potassium hydroxide 7g, nitrogen replacement 3 times, heat up and turn on the vacuum pump, carry out vacuum dehydration at 100-105°C for 3 hours, then cool down to 80°C, and start adding propylene oxide dropwise , by controlling the feeding speed of propylene oxide and the temperature control device, the reaction temperature in the kettle is maintained at 80-110°C, and the pressure is in the range of 0.1-0.4MPa until the propylene oxide is added to 1500g. After the feeding is completed, the reaction is matured for 3 Hour. Adding water and acid to the matured product, adding an adsorbent, dehydrating and degassing in a vacuum, and press-filtering to obtain fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com