Machining process for thin-wall aluminum volute

A machining and volute technology, applied in the field of centrifugal fan casing processing, can solve the problems of complex processing technology, low processing efficiency, and unstable size of thin-walled cast aluminum volute, and achieve good dimensional stability, high processing efficiency, and installation. The effect of fewer clips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

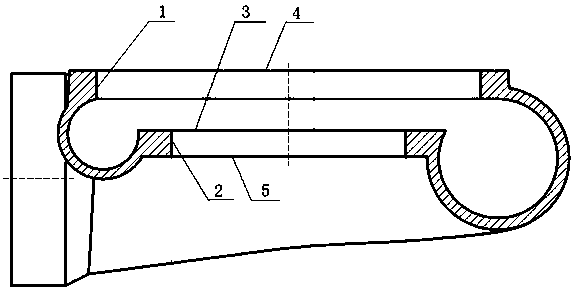

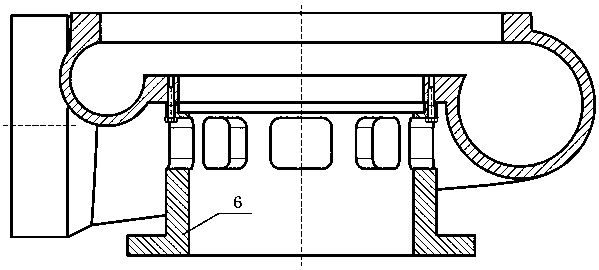

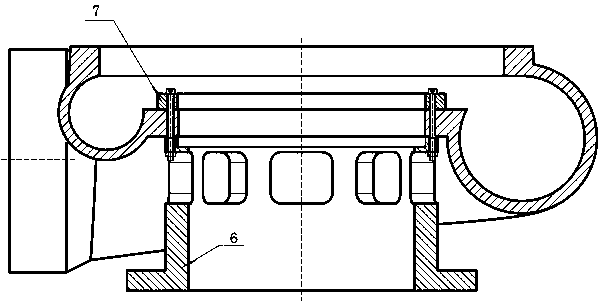

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0025] Such as Figure 1-Figure 5 As shown, in this embodiment, a machining process for a thin-walled cast aluminum volute includes the following steps:

[0026] 1) Select the rough machining benchmark, select the upper end surface 4 of the volute and the inner hole 2 as the rough machining benchmark.

[0027] 2) Machining datum plane and threaded holes, on the vertical machining center, the rough machining datum positioning milling bottom surface 5 is used as the datum plane, and 8 M6 threaded holes are drilled on the bottom surface 5.

[0028] 3) To install the base tooling 6, first fix the base tooling 6 on the workbench of the vertical machining center, the base tooling 6 is a thick-walled tubular structure, the diameter of its inner hole is slightly larger than the diameter of the inner hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com