Polyamide resin and preparation method thereof and polyamide material prepared from same

A polyamide resin, polyamide technology, applied in the field of polymer materials, can solve the problems of insufficient thermal oxidation stability, insufficient dimensional stability, limited application fields, etc., and achieve improved thermal oxidation stability, transparency and mechanical properties. The effect of improving retention and reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

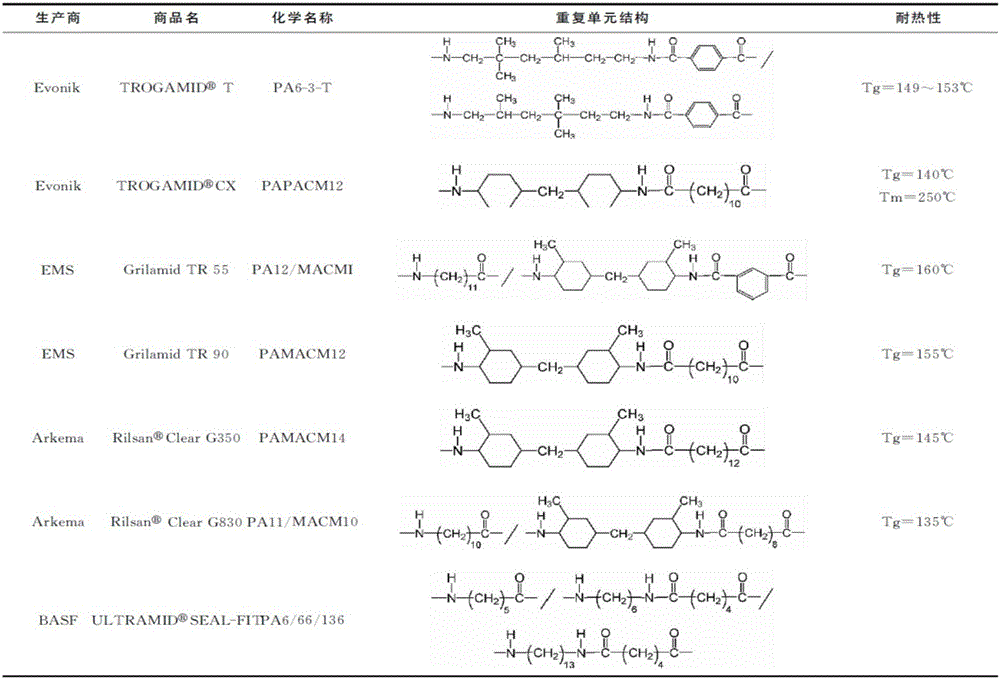

Image

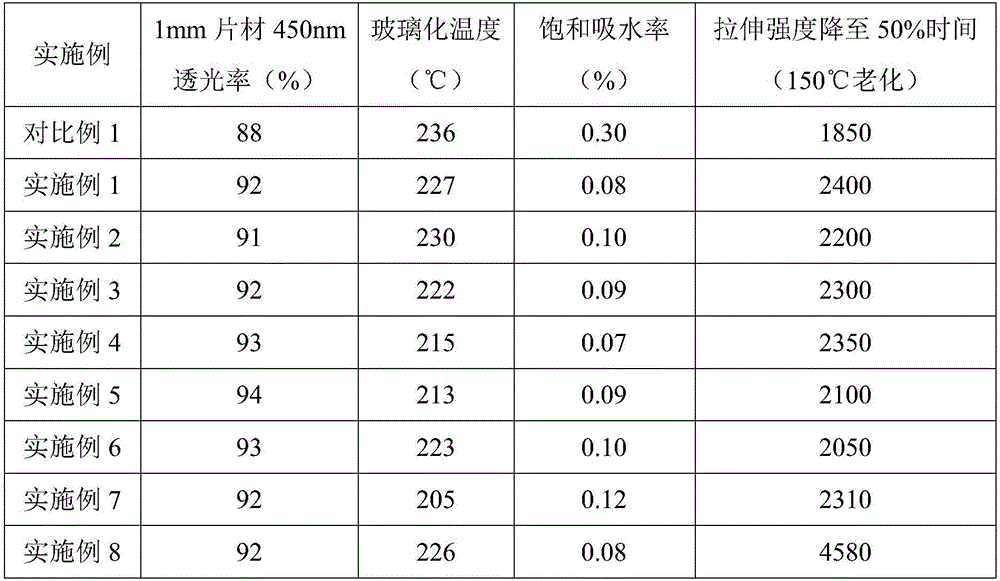

Examples

Embodiment 1

[0034] Add 238.09g of 2,3,5,6-tetrafluoroterephthalic acid, 210.36g of bis(4-aminocyclohexyl)methane, and 400g of absolute ethanol into a 1000ml glass bottle, and stir and heat the reaction at 50°C After 1 hour, an amide salt precipitate was generated, and the precipitate was filtered and dried to obtain a pure amide salt solid;

[0035] Add the amide salt into a 1L stainless steel reaction kettle, add 50g of distilled water, replace with nitrogen, and then heat in a sealed environment. The temperature rises to 250°C, the pressure is 1.2MPa, and the temperature and pressure are maintained for 1 hour to obtain a polyamide prepolymer;

[0036] Slowly release the pressure of the system to normal pressure, continue to feed nitrogen to carry out normal pressure polymerization, increase the polymerization temperature to 300 ° C, and the polymerization time to be 3 hours, after the polymerization is completed, add 1 wt% of the product quality antioxidant masterbatch (carrier resin Th...

Embodiment 2

[0038] In a 1000ml glass bottle, add 119.04g 2,3,5,6-tetrafluoroterephthalic acid, 83.06g terephthalic acid, 214.57g bis(4-aminocyclohexyl)methane, and 400g anhydrous methanol, and in Stir and heat the reaction at 75°C for 1 hour to form an amide salt precipitate, filter and dry the precipitate to obtain a pure amide salt solid;

[0039] Add the amide salt into a 1L stainless steel reaction kettle, add 100g of distilled water, replace with nitrogen and heat in a closed manner, the temperature rises to 280°C, the pressure is 2.7MPa, and the temperature and pressure are maintained for 2 hours to obtain a polyamide prepolymer;

[0040] Slowly release the pressure of the system to normal pressure, continue to feed nitrogen to carry out normal pressure polymerization, raise the polymerization temperature to 300°C, and polymerize for 3 hours. After the polymerization is completed, add 3wt% antioxidant masterbatch and mix evenly. The pellets contain 10% mass fraction of 1098 and 126 ...

Embodiment 3

[0042] In a 1000ml glass bottle, add 119.04g 2,3,5,6-tetrafluoroterephthalic acid, 83.06g isophthalic acid, 214.57g bis(4-aminocyclohexyl)methane, and 400g anhydrous methanol, and in Stir and heat the reaction at 75°C for 1 hour to form an amide salt precipitate, filter and dry the precipitate to obtain a pure amide salt solid;

[0043] Add the amide salt into a 1L stainless steel reaction kettle, add 100g of distilled water, replace with nitrogen and heat in a closed manner, the temperature rises to 280°C, the pressure is 2.7MPa, and the temperature and pressure are maintained for 2 hours to obtain a polyamide prepolymer;

[0044] Slowly release the pressure of the system to normal pressure, continue to feed nitrogen to carry out normal pressure polymerization, raise the polymerization temperature to 300°C, and polymerize for 3 hours. After the polymerization is completed, add 3wt% antioxidant masterbatch and mix evenly. The pellets contain 10% mass fraction of 1098 and 126 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com