Piezoelectric ceramic composition

A technology of piezoelectric ceramics and composites, applied in circuits, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve problems that are not suitable for general sensors and actuators, and achieve improved mechanical quality factors, Excellent piezoelectric performance, the effect of reducing the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

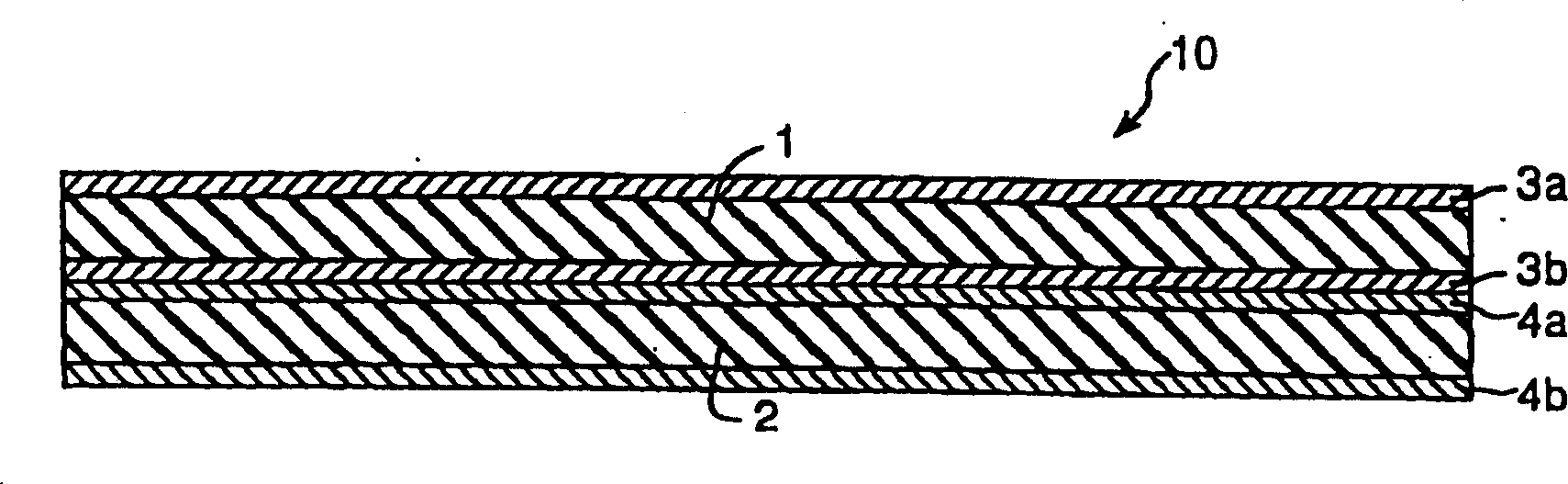

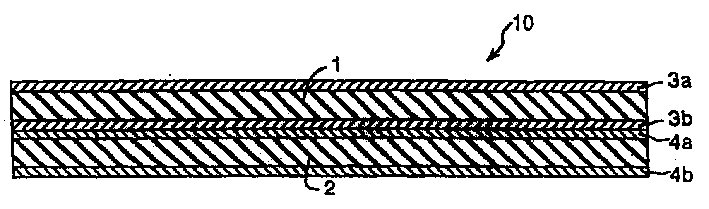

Image

Examples

Embodiment 1

[0034] The piezoelectric ceramic composition according to Example 1 was prepared as follows. First, weigh BaCO as a raw material 3 , Bi 2 o 3 , NaCO 3 , CaCO 3 ,TiO 2 and MnCO 3 , and finally obtain piezoelectric ceramics that may have a given formulation ratio as shown in Table 1, and mix them uniformly in a ball mill. Next, it is calcined at a temperature of 800-1,000° C. for 2 hours to form a compound. The compound is ground again in a ball mill, polyvinyl alcohol is added to the compound granules, and the mixture is granulated. The granulated powder was uniaxially compression molded under a pressure of 70 MPa to form a disc with a diameter of 13 mm, which was then heated at 1000-1400° C. for 2 hours.

[0035] The disk-shaped sample was ground to a thickness of 0.3 mm, and Ag was baked and fused at 700° C. to condense on the sample disk to form electrodes thereon. Thereafter, the sample disk was subjected to polarization treatment by applying an electric field of 3...

Embodiment 2

[0043] A piezoelectric ceramic composition according to Example 2 was prepared as follows. First, weigh BaCO as a raw material 3 , Bi 2 o 3 , NaCO 3 , CaCO 3 ,TiO 2 , ZnO, Nb 2 o 5 and MnCO 3 , and finally obtain piezoelectric ceramics having a given formulation ratio as shown in Table 3, and uniformly mix them in a ball mill. Next, it is calcined at a temperature of 800-1,000° C. for 2 hours to form a compound. The compound is ground again in a ball mill, polyvinyl alcohol is added to the compound granules, and the mixture is granulated. The granulated powder was uniaxially compression molded under a pressure of 70 MPa to form a disc with a diameter of 13 mm, which was then heated at 1200-1400° C. for 2 hours. The disk-shaped sample was ground to a thickness of 0.3 mm, and Ag was baked and fused at 700° C. to condense on the sample disk to form electrodes thereon. Thereafter, the sample disk was subjected to polarization treatment by applying an electric field of 3...

Embodiment 3

[0051] A piezoelectric ceramic composition according to Example 3 was prepared as follows. First, weigh BaCO as a raw material 3 , Bi 2 o 3 , NaCO 3 , CaCO 3 ,TiO 2 , MnCO 3 , Y 2 o 3 , Dy 2 o 3 , Ho 2 o 3 and Yb 2 o 3 , and finally obtain piezoelectric ceramics with the preparation ratio shown in Table 5, and uniformly mix them in a ball mill. Next, it is calcined at a temperature of 800-1,000° C. for 2 hours to form a compound. The compound is ground again in a ball mill, polyvinyl alcohol is added to the compound granules, and the mixture is granulated. The granulated powder was uniaxially compression molded under a pressure of 70 MPa to form a disc with a diameter of 13 mm, which was then heated at 1200-1400° C. for 2 hours.

[0052] The disk-shaped sample was ground to a thickness of 0.3 mm, and Ag was baked and fused at 700° C. to condense on the sample disk to form electrodes thereon. Thereafter, the sample disk was subjected to polarization treatment b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com