Hydrophilic lithium sulfonate terpolymer and preparation method thereof

A terpolymer and lithium sulfonate technology are applied in the fields of hydrophilic lithium sulfonate terpolymer and its preparation, lithium ion polymer and its preparation, and can solve the problems of low chemical stability and low performance of the copolymer, and the like, Achieve the effect of improving charge and discharge performance, improving chemical stability, and reducing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] This embodiment provides a hydrophilic lithium sulfonate terpolymer.

[0078] It should be noted:

[0079] The monomer compounds involved in this example are all commercially available.

[0080] A kind of hydrophilic lithium sulfonate terpolymer provided by the present embodiment comprises:

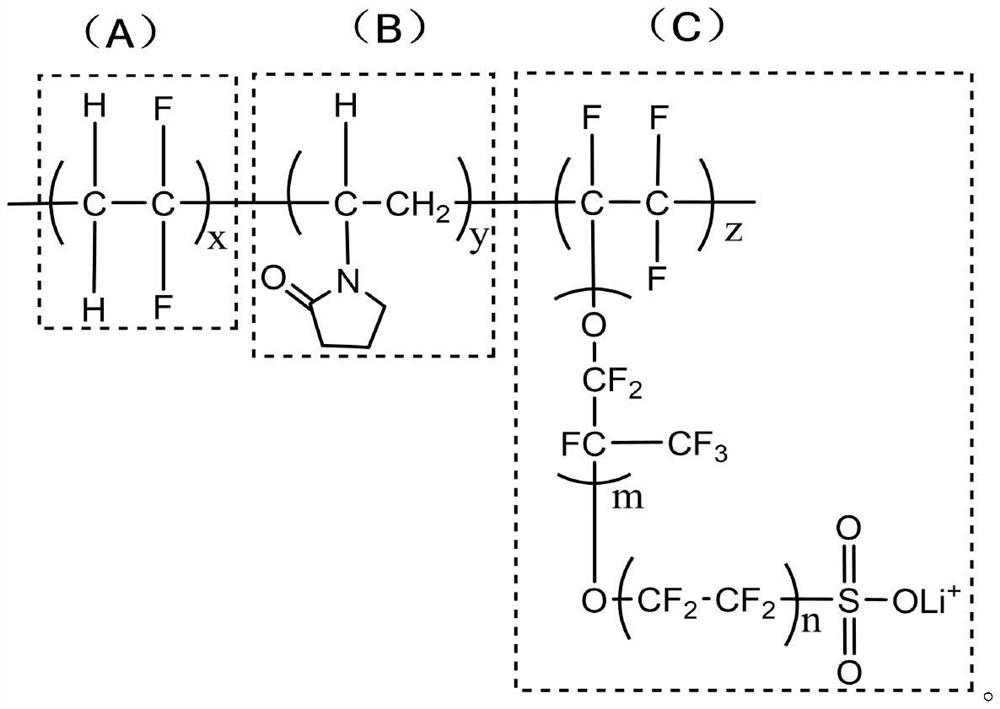

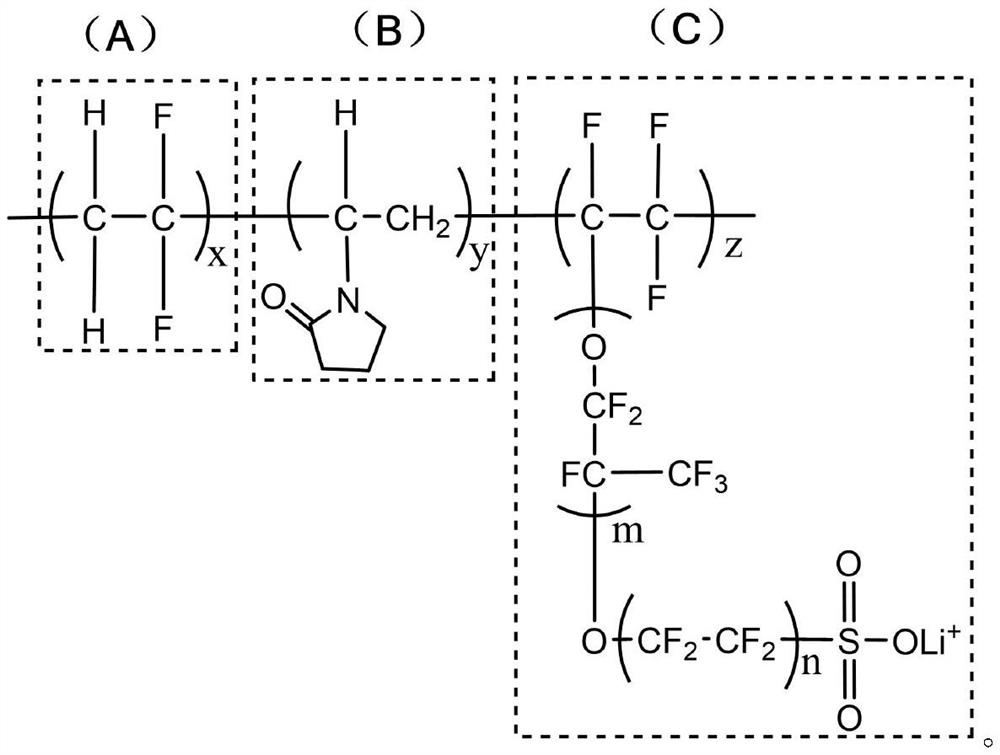

[0081] Polyvinylidene fluoride structural unit (A) composed of x molar parts of vinylidene fluoride monomer, vinylpyrrolidone structural unit (B) composed of y molar parts of vinylpyrrolidone monomer and z molar parts of lithium perfluorovinyl ether sulfonate The perfluorovinyl ether sulfonate lithium structural unit (C) three kinds of compound structural units of the copolymer formed;

[0082] And the copolymer has the following general structural formula:

[0083]

[0084] in:

[0085] The respective mole fractions of polyvinylidene fluoride structural unit, vinylpyrrolidone structural unit and perfluorovinyl ether sulfonate lithium structural unit are respectively:

[00...

Embodiment 2

[0101] This embodiment provides a preparation method of a hydrophilic lithium sulfonate terpolymer.

[0102] It should be noted:

[0103] The reaction device, monomer compound, initiator, emulsifier, demulsifier, and organic solvent involved in this example are all commercially available.

[0104] A preparation method of hydrophilic lithium sulfonate terpolymer, comprising the steps of:

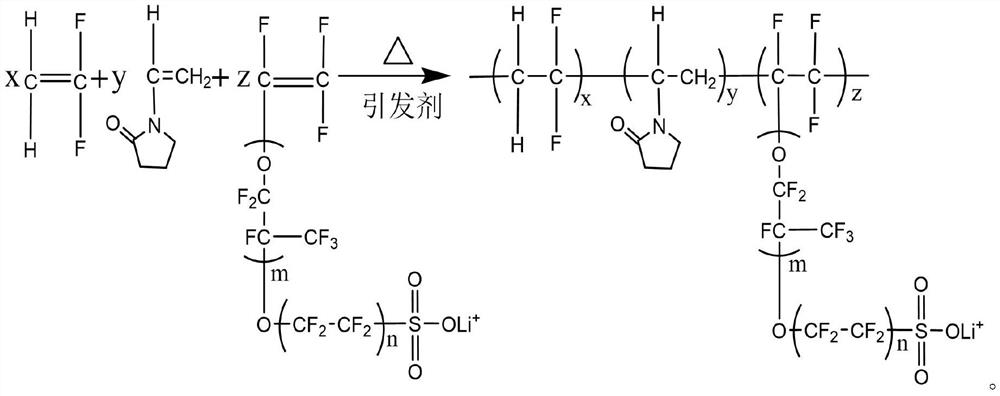

[0105] In the reaction device, vinylidene fluoride monomer, vinylpyrrolidone monomer, lithium perfluorovinyl ether sulfonate and initiator are respectively added, and the hydrophilic lithium sulfonate terpolymer is produced by copolymerization by polymerization reaction method;

[0106] Its reaction formula is:

[0107]

[0108] Further, in the above preparation method:

[0109] The reaction device is a high-pressure reactor;

[0110]The steps of adding vinylidene fluoride monomer, vinylpyrrolidone monomer, lithium perfluorovinyl ether sulfonate and initiator respectively include:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com