Rigid polyurethane foam and preparation method thereof

A technology of rigid polyurethane and hyperbranched polyurethane, which is applied in the field of polyurethane foam preparation, can solve problems such as difficulty in mixing uniformly, emission of volatile organic compounds, inhomogeneous rigid foam, etc., and achieve simple process, improved dimensional stability, and temperature resistance good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, 6.7 parts by weight of trimethylolpropane and 33.3 parts by weight of isophorone diisocyanate are added to a three-necked flask, and then 0.05 parts by weight of organic bismuth catalyst (BiCAT 8108, leading in the United States) is added. , reacted in N-dimethylformamide for 1 hour; then added 60 parts by weight of trimethylolpropane to continue the reaction for 3 hours to obtain a hyperbranched polyurethane polyol with a solid content of 71% and a viscosity of 1100 mPa·s.

[0031] At 30°C, add 100 parts by weight of hyperbranched polyurethane polyol, 8.5 parts by weight of water, and 4 parts by weight of organosiloxane (B8433, Degussa) into a self-made mold and stir for 30 seconds. After mixing evenly, quickly add 180 parts by weight Polymethylene polyphenyl polyisocyanate (PM-200, Yantai Wanhua), after stirring for 3 minutes, was placed in an oven at 60° C. for curing for 24 hours to prepare the rigid polyurethane foam.

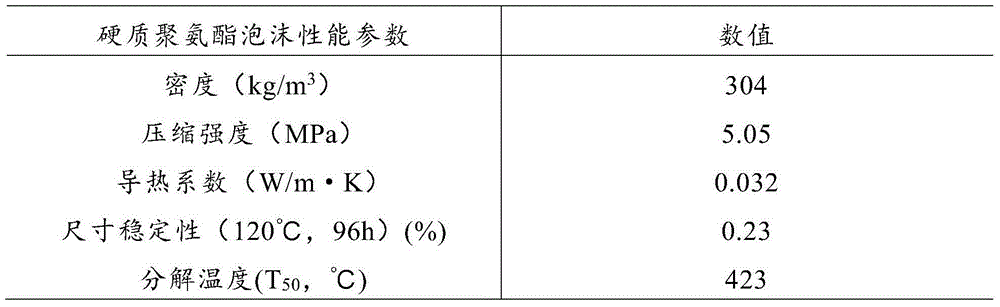

[0032] The performance test of rigid p...

Embodiment 2

[0036] First, 6.7 parts by weight of trimethylolpropane and 40 parts by weight of isophorone diisocyanate were added to a three-necked flask, then 0.10 parts by weight of dibutyltin dilaurate was added, and 40 parts by weight of N,N-dimethyl and then added 40 parts of trimethylolpropane to continue the reaction for 4 hours to obtain a hyperbranched polyurethane polyol with a solid content of 68% and a viscosity of 960 mPa·s.

[0037] At 30°C, add 100 parts by weight of hyperbranched polyurethane polyol, 8.5 parts by weight of water, and 2.8 parts by weight of organosiloxane (AK8805, Demei Shichuang) into a self-made mold and stir for 30 seconds. After mixing evenly, quickly add 140 parts by weight Polymethylene polyphenyl polyisocyanate (PM-200, Yantai Wanhua), after stirring for 3 minutes, was placed in an oven at 40° C. for curing for 48 hours to prepare the rigid polyurethane foam.

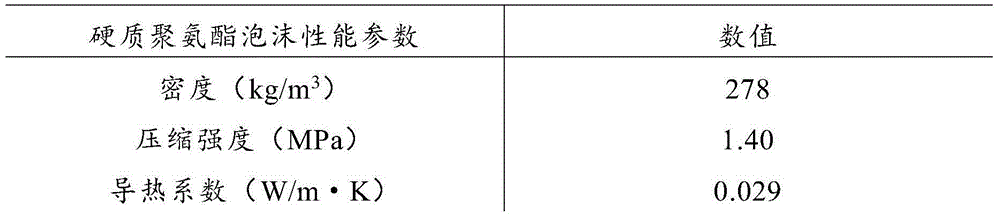

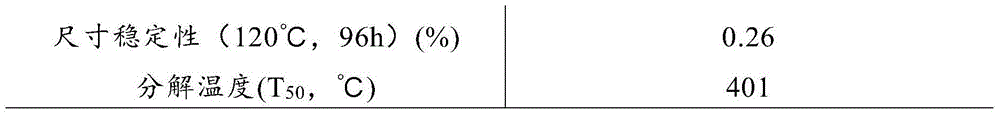

[0038] The performance test of rigid polyurethane foam was carried out, and the results are...

Embodiment 3

[0043] First, 6.7 parts by weight of trimethylolpropane and 50 parts by weight of isophorone diisocyanate are added to a three-necked flask, and then 0.15 parts by weight of organic bismuth catalyst (BiCAT 8118, leading in the United States) is added. , reacted in N-dimethylformamide for 2 hours; then added 45 parts by weight of trimethylolpropane to continue the reaction for 4 hours to obtain a hyperbranched polyurethane polyol with a solid content of 70% and a viscosity of 1050 mPa·s.

[0044] At 30°C, add 100 parts by weight of hyperbranched polyurethane polyol, 8.5 parts by weight of water, and 4 parts by weight of organosiloxane (B8450, Degussa) into a self-made mold and stir for 30 seconds. After mixing evenly, quickly add 240 parts by weight Polymethylene polyphenyl polyisocyanate (5005, Huntsman) was stirred for 3 minutes, and then put into an oven at 80° C. for 12 hours to cure to prepare the rigid polyurethane foam.

[0045] The performance test of rigid polyurethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com