Inclined roller bearing

A roller bearing and inclined technology, applied in the field of double-row inclined roller bearings, can solve the problem of large radial expansion of the bearing ring, and achieve the effect of reducing radial expansion, lack of installation space and improving running performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

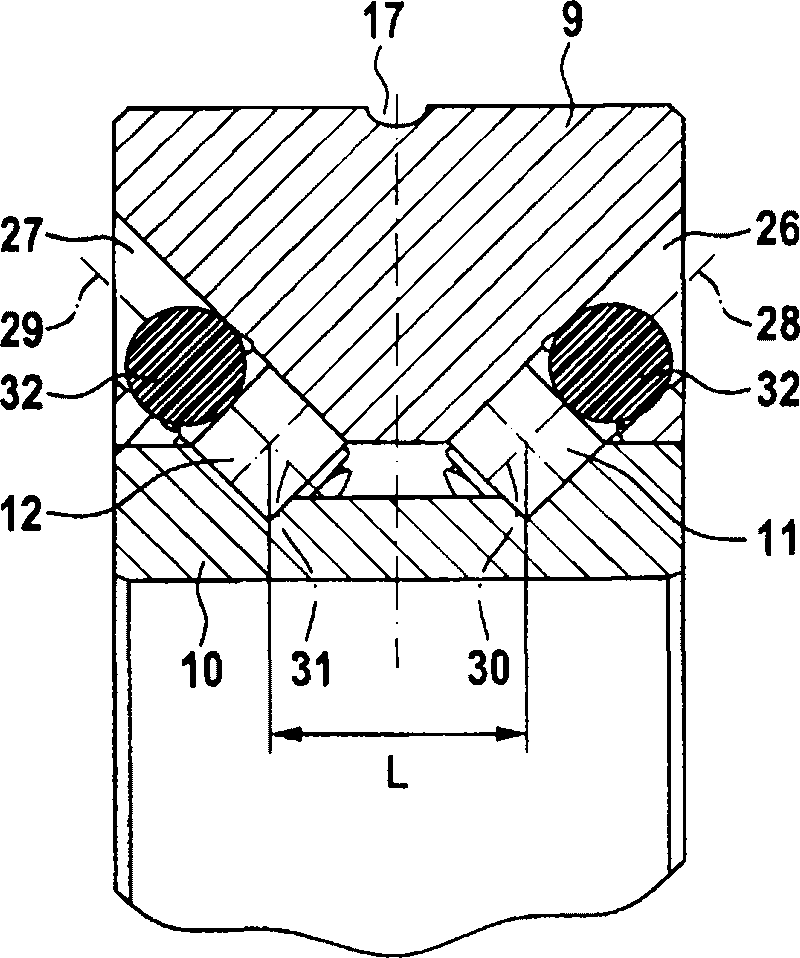

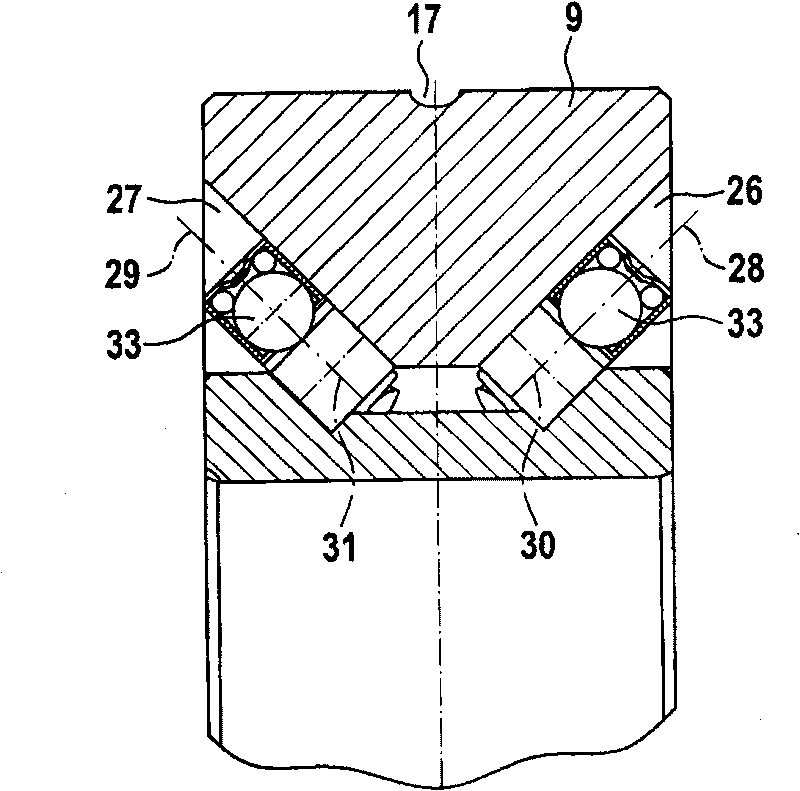

[0018] To illustrate the prior art, first refer to Figure 5 . The double-row skewed roller bearing shown here consists of outer bearing rings 1 and inner bearing rings 2 which are arranged concentrically to each other around a bearing axis 6 . Cylindrical rolling bodies 3, 4 roll between the two bearing rings 1, 2. The rolling bodies 3 , 4 are fed to the bearing through filling openings (not shown) in the inner bearing ring 2 , so that the bearing is filled with the rolling bodies 3 , 4 . After the filling process, the filling opening is closed with a plug 7 which must be fixed again in the inner bearing ring 2 using the fastening screw 5 . Obviously, when the distance L between the two rolling elements 3, 4 along the axial direction (according to Figure 5 As L) becomes larger, the stuffing element 7 must also be adapted accordingly. The invention should therefore now enable a simplified design of such a bearing.

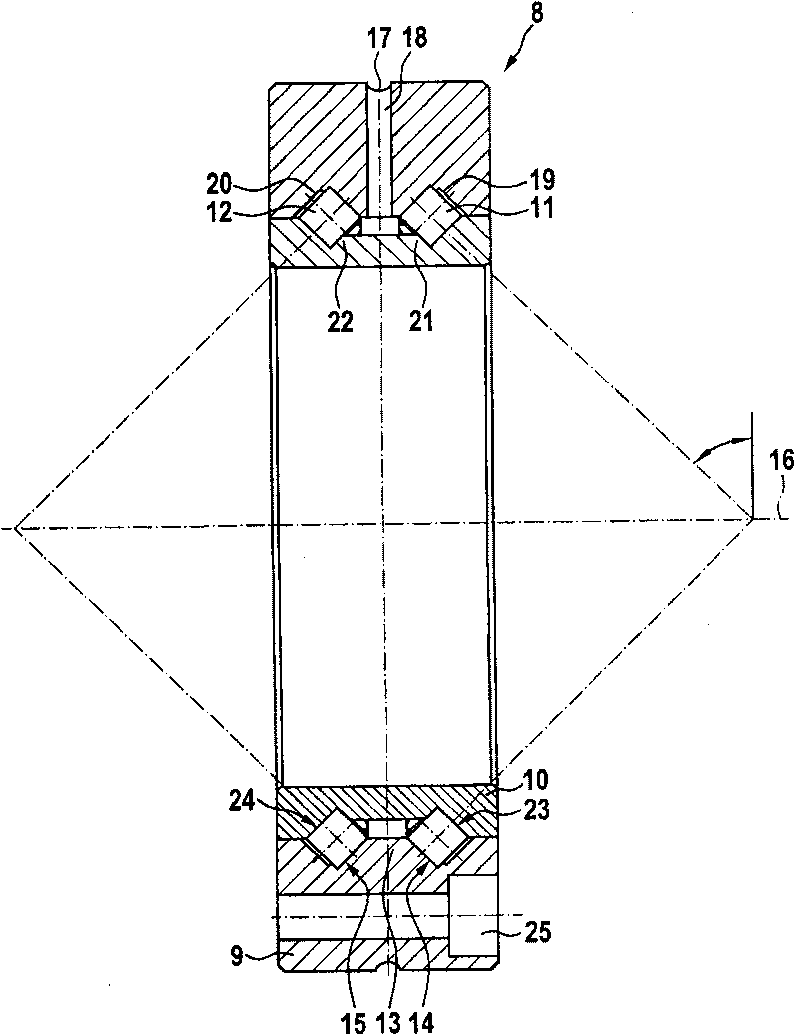

[0019] like figure 1 As shown, the skewed roller beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com