Logical control method for evaporative cooling of inductive type vibration equipment

A vibrating equipment and evaporative cooling technology, which is applied to the structural parts of electrical equipment, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of cooling air flow reduction, affecting cooling efficiency, and increasing wind pressure, etc., to achieve reduction The effect of radial expansion, reliable function and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

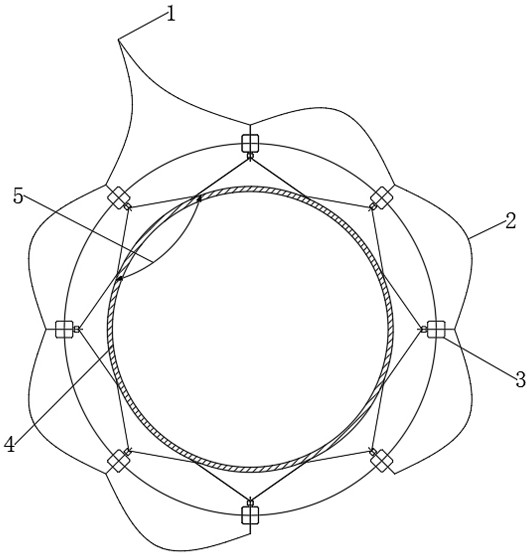

[0028] The present invention will be further described below with reference to the accompanying drawings:

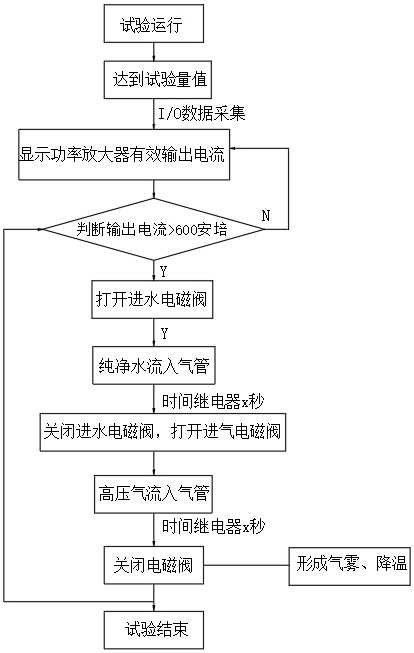

[0029] Induction Vibration Equipment Evaporative Cooling Logic Control Method, which includes the following steps:

[0030] (1) Test operation:

[0031] Step 1: Turn on the vibration device to collect data;

[0032] Step 2: The power amplifier displays the effective output current and determines whether the effective output current is greater than 600 amps;

[0033] (2) Effective output current is greater than 600 amps:

[0034] Step 1: Open the water solenoid valve, the time relay is automatically timed, pure water flows into the trachea;

[0035] Step 2: After the water supply time is reached, turn off the water solenoid valve, open the intake solenoid valve, the intake relay automatically time, the high pressure air flow enters the trachea, and the intake electromagnetic valve is turned off.

[0036] Step 3: The high pressure gas flow in the trachea can spray pure water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com