Touch sensation force feedback simulation model modeling method

A technology of simulation model and modeling method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve the problems that the tactile force feedback simulation model cannot meet the requirements of virtual clay modeling technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

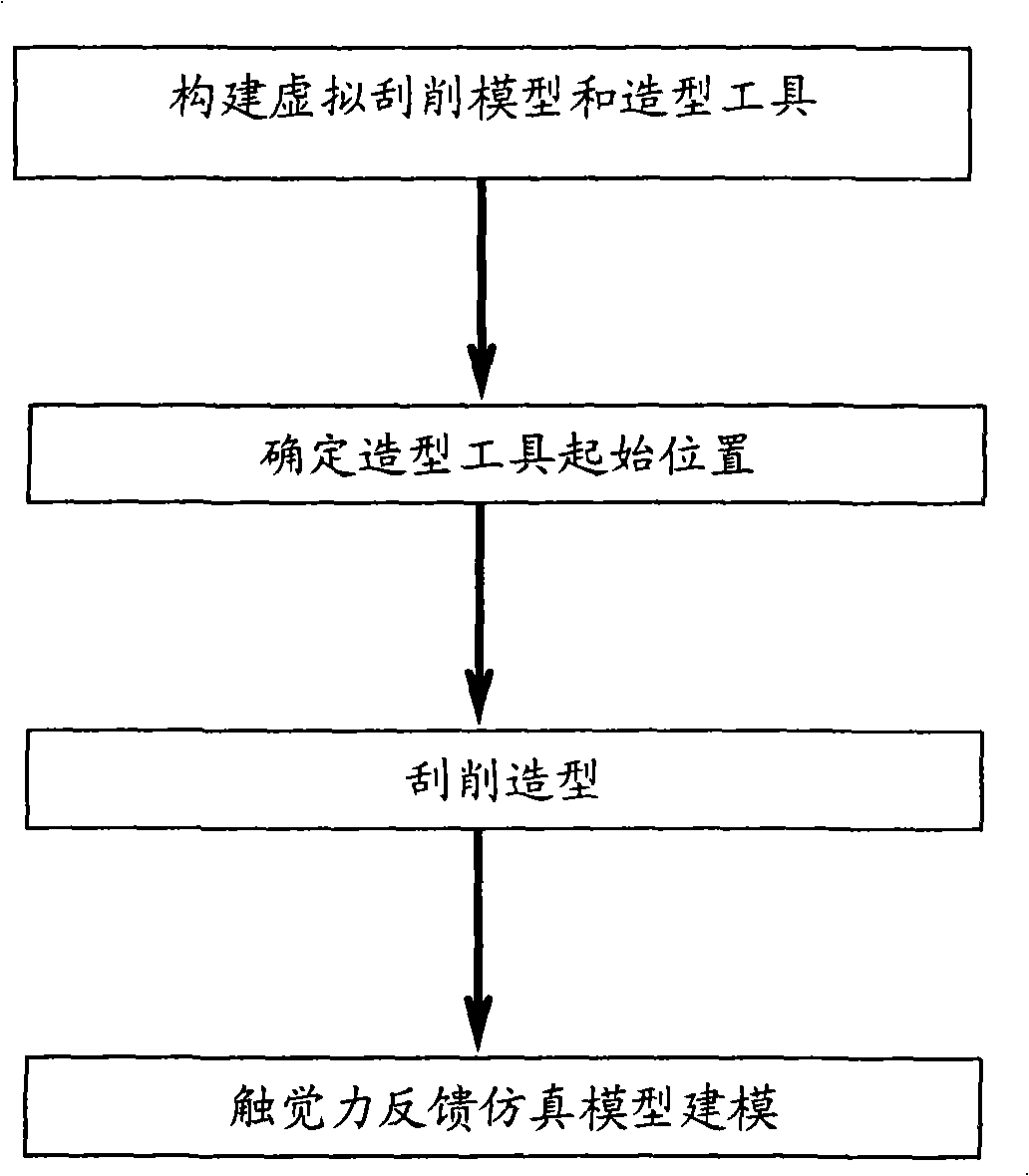

[0017] Refer to attached picture.

[0018] The present invention is illustrated by taking the modeling experiment of the tactile force feedback simulation model based on the material removal rate as an example.

[0019] 1. Build virtual scraping models and modeling tools.

[0020] In this embodiment, the virtual scraping model is a cube with a size of 15 mm×15 mm×15 mm. The modeling tool is a rectangular flat scraper. According to the size of the virtual scraping model, the rectangular flat scraper is selected to be 20 mm long, 5 mm wide, and 0.5 mm thick. Use solid modeling techniques to construct virtual scraping models and modeling tools.

[0021] 2. Determine the starting position of the modeling tool.

[0022] Move the modeling tool through the Phantom Desktop force feedback device to make it contact with the surface of the virtual scraping model, and the current position of the modeling tool is its starting position. Whether the modeling tool is in contact with the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com