Method for manufacturing display device

A technology for display devices and transfer layers, applied in lighting devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of low luminous efficiency, short brightness half-life, etc., achieve high luminous efficiency, realize cost, good The effect of material usage and productivity

Inactive Publication Date: 2008-09-24

SONY CORP

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] However, although the use of such thermal transfer printing is advantageous in the process of miniaturizing light-emitting elements, this method is accompanied by

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

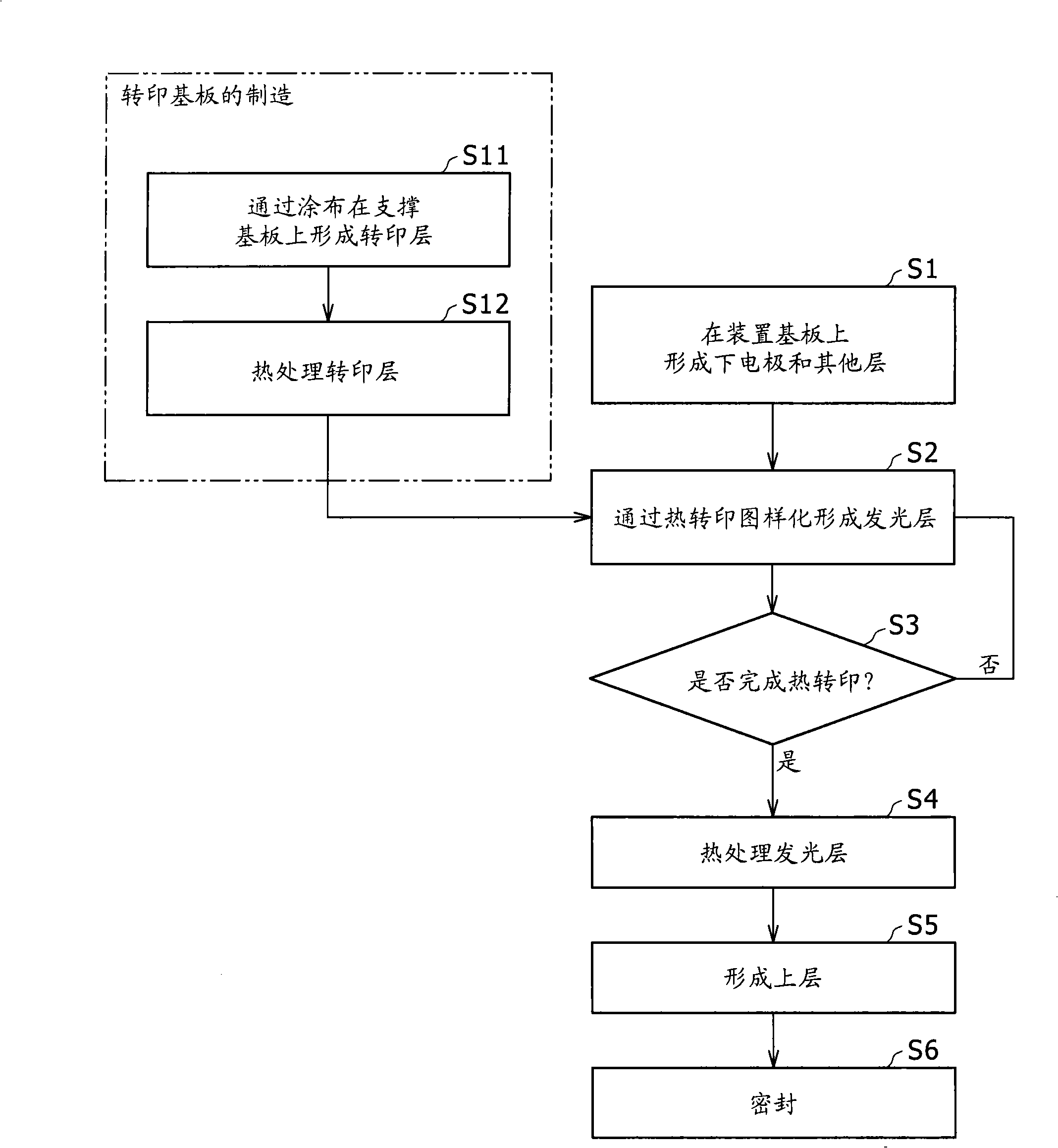

Disclosed herein above is a method for manufacturing a display device, the method including the steps of: forming a transfer layer containing an organic light-emitting material over a support substrate by coating; heat-treating the transfer layer over the support substrate; and thermally transferring the heat-treated transfer layer over a device substrate.

Description

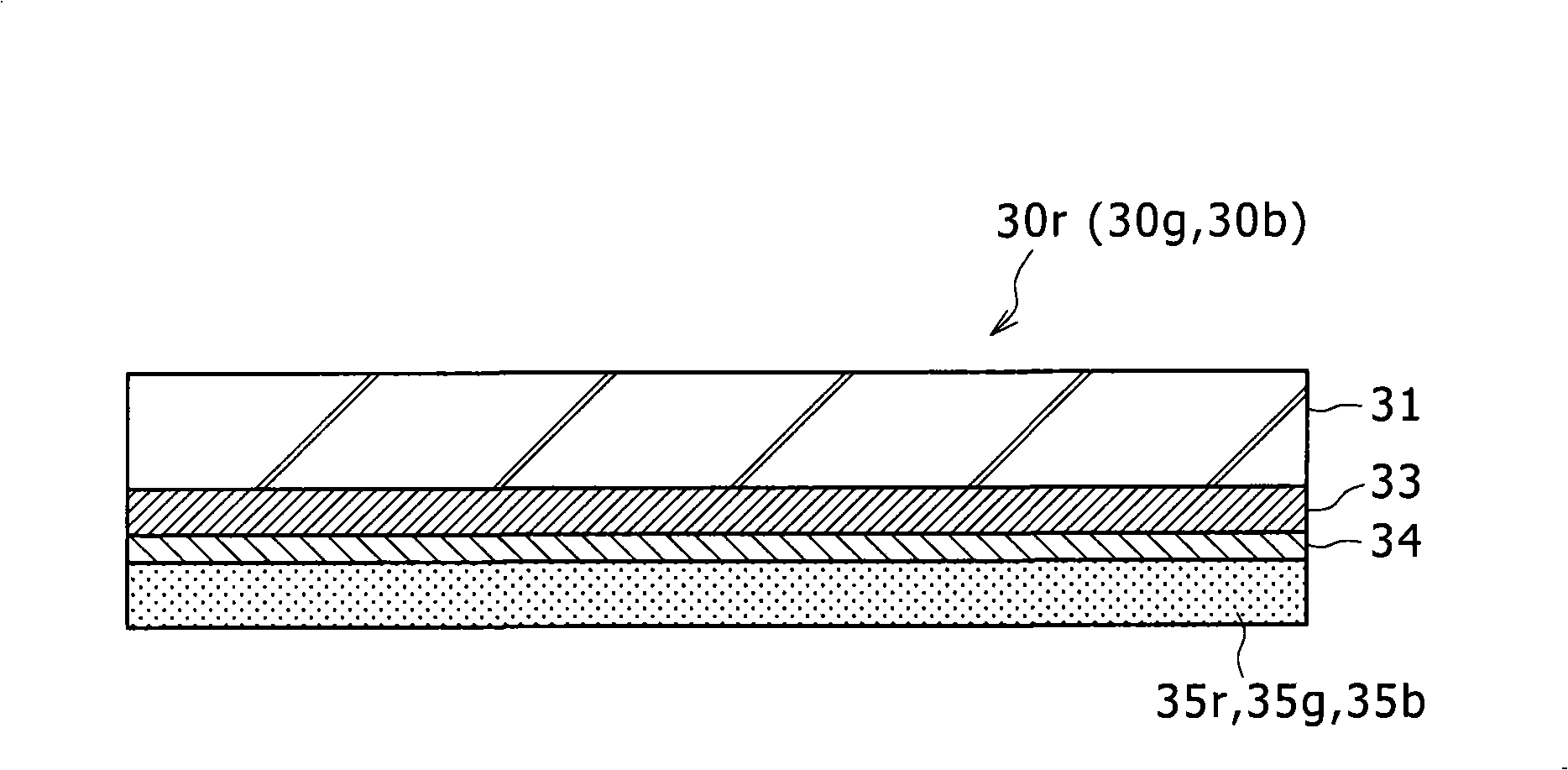

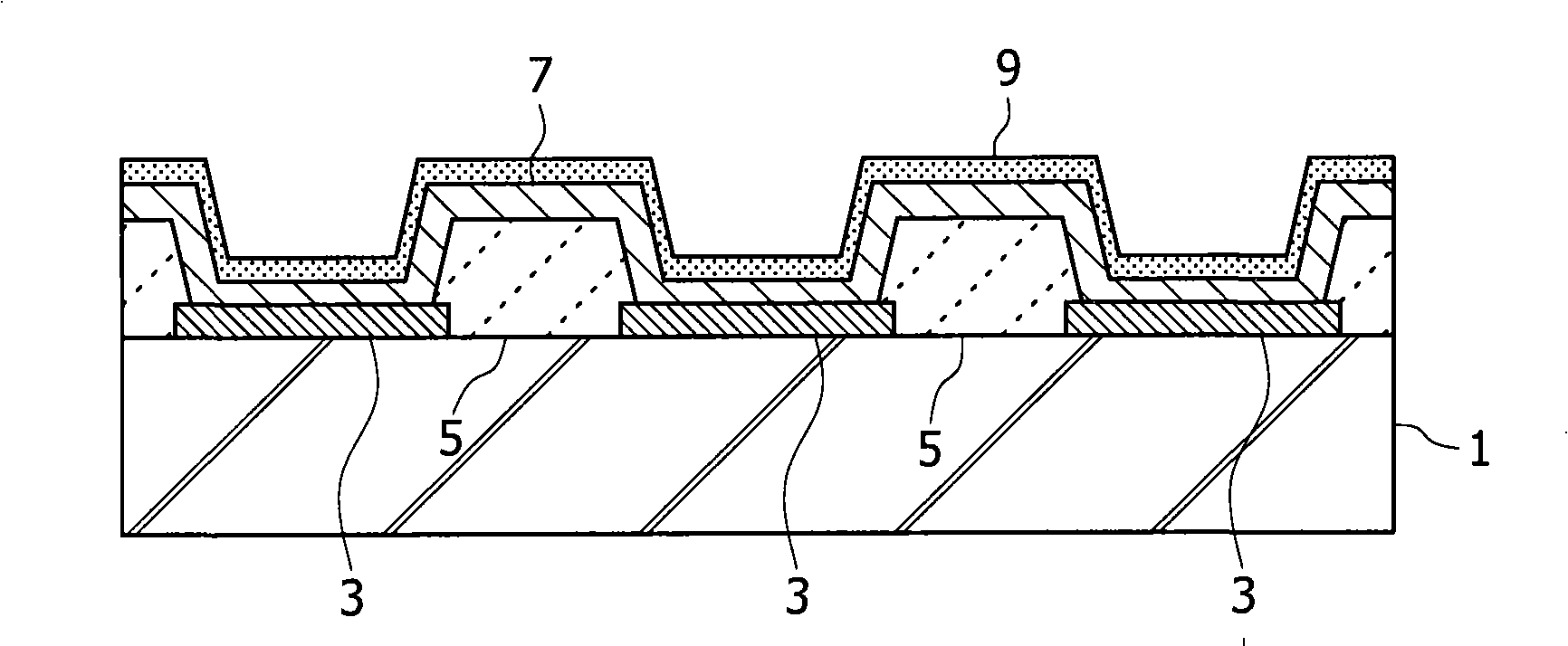

[0001] Cross References to Related Applications [0002] The present invention contains subject matter related to Japanese Patent Application JP 2007-072965 filed in the Japan Patent Office on Mar. 20, 2007, the entire content of which is hereby incorporated by reference. technical field [0003] The present invention relates to a method for manufacturing a display device, and more particularly, to a method for manufacturing an electroluminescent element that uses an organic electroluminescent element and that is still light-emitting even if a coating film deposition method and a thermal transfer method are applied to form its light-emitting layer. A method for a display device capable of maintaining a sufficiently high luminous efficiency and a sufficiently long luminance half-life. Background technique [0004] An organic electroluminescent element using electroluminescence of an organic material is formed by disposing an organic layer obtained by stacking a hole transport...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05B33/10H05B33/26B41M3/12

CPCH05B33/10H01L51/56H01L51/0026Y02E10/549H01L51/0013C23C14/048Y02P70/50H10K71/18H10K71/40H10K71/00

Inventor 镜庆一松尾圭介小日向好吉松田英介

Owner SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com