Roll mill

A mill and roller technology, applied in mechanical equipment, threaded fasteners, pipe supports, etc., can solve problems such as adverse product effects, material retention, and difficulty in cleaning baffles, achieving easy disassembly, convenient cleaning, Simple flip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

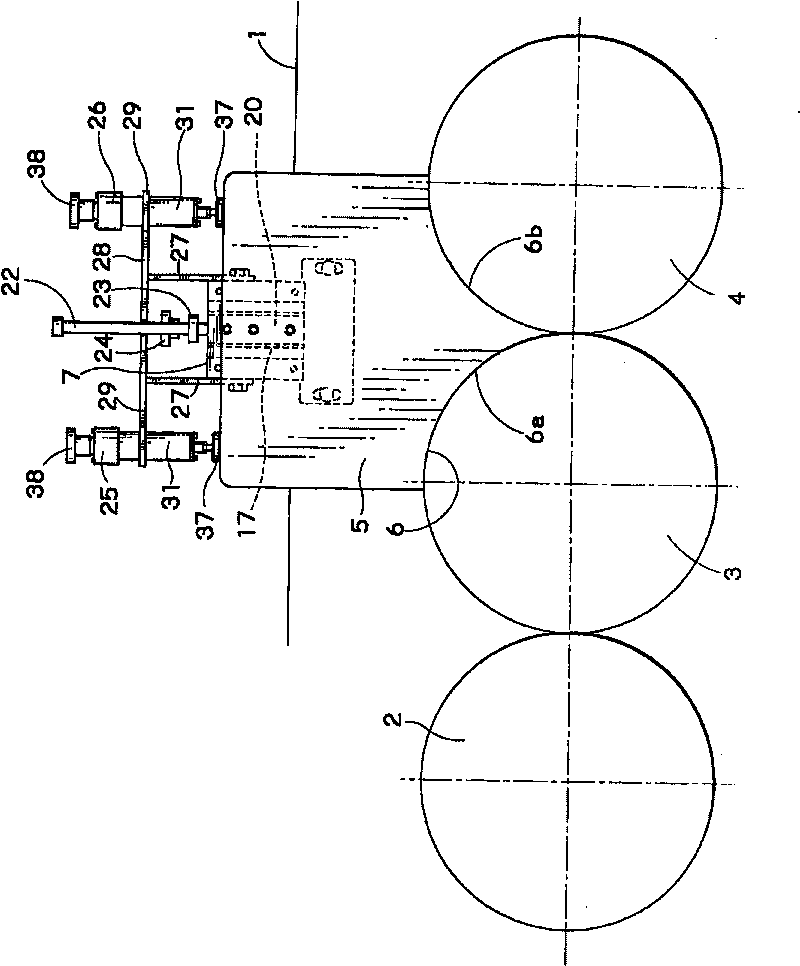

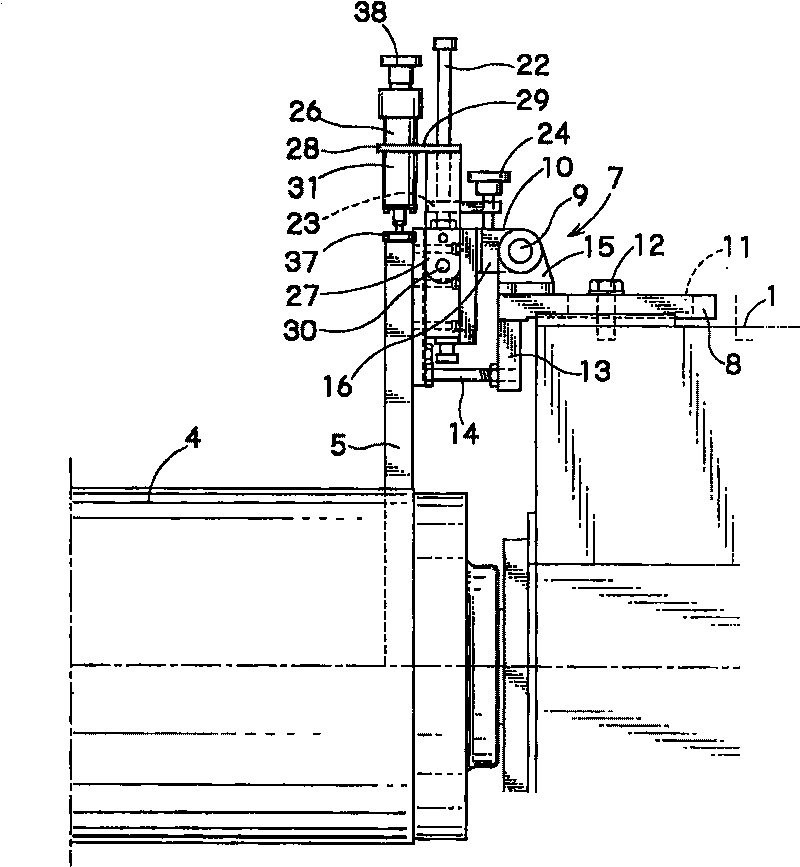

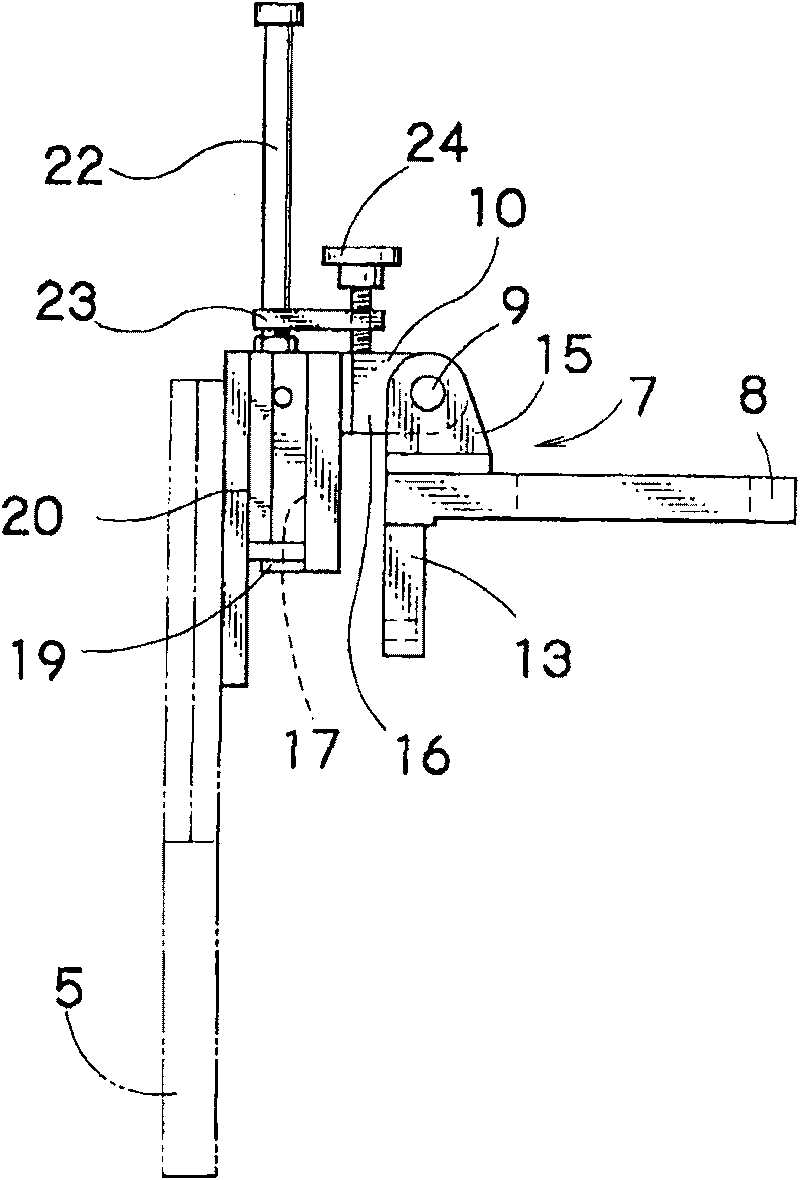

[0018] The present invention can be applied to various roller mills that use multiple rollers with different rotation speeds to grind and disperse processing materials. In the embodiment shown in the figure, there are three rollers adjacent to each other in the front and rear directions. Of three roller mills. Reference figure 1 , 2 , The front roller 2, the middle (center) roller 3, and the rear (supply) roller 4 are adjacently arranged on the roller mill main body 1 in the front-rear direction, and the rotation speed of each roller is from the rear roller 4 to the front roller 2 side in order increase.

[0019] A baffle plate 5 is provided between the ends of the aforementioned rear roller 4 and the middle roller 3 to block the gap between the rollers. The lower end of the baffle 5 is formed with a lower end surface 6 having curved surfaces 6a, 6b that are curved corresponding to the peripheral surfaces of the rear roller 4 and the middle roller 3 at the front and rear. The ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com