Method for rounding honing bar by utilizing honing head

A technology of honing heads and honing sticks, which is applied in the field of honing processing, can solve the problems of a large number of parts, aggravate the vibration of the outer diameter of the honing sticks, and the axial dimension is too long, so as to improve the accuracy of the circle, avoid adverse effects, and prevent the accuracy of effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Gauging a single-feed honing head

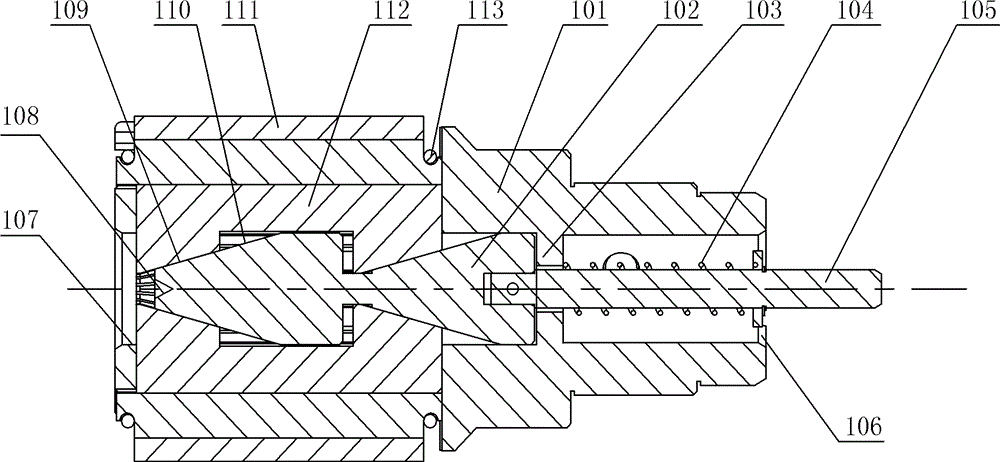

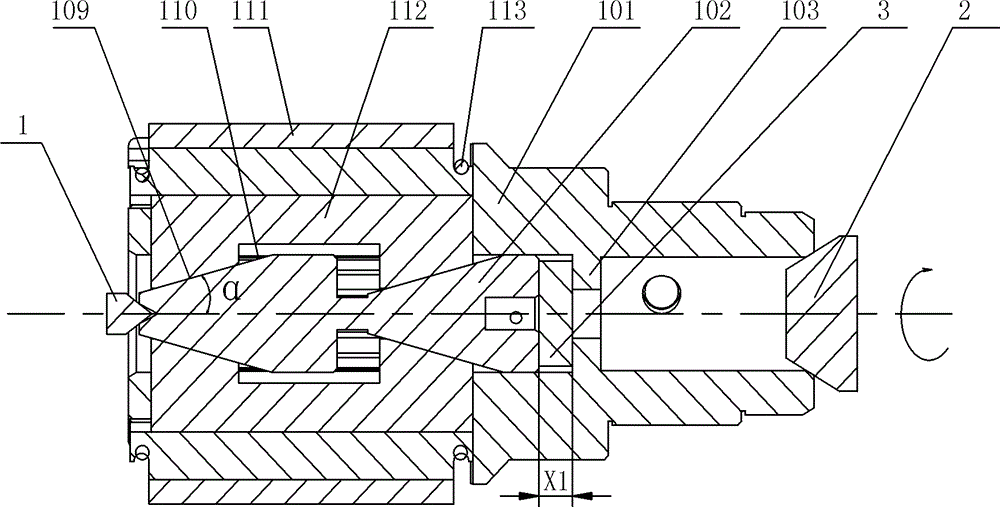

[0025] Such as figure 1 As shown, the single-feed honing head includes a hollow cylindrical honing head body 101 with a central hole 107 at the front end and a central hole 106 at the rear end of the honing head body 101 . The honing head body 101 is provided with an expanding mandrel 102 that can slide axially, and the inner wall of the honing head body 101 is provided with a retaining wall 103 for limiting the sliding range of the expanding mandrel 102 . The front end of the expansion mandrel 102 is provided with a central hole 108, and the central hole 108 is on the same axis as the central hole 107 and the central hole 106. The rear end of the expansion mandrel 102 is detachably connected with a push rod 105, the push rod 105 is covered with a return spring 104, and a plurality of honing rod bases 112 are arranged on the honing head body 101 along the circumferential direction, and the honing rod base 112 It is con...

Embodiment 2

[0031] Embodiment 2: Gauging the double-feed honing head

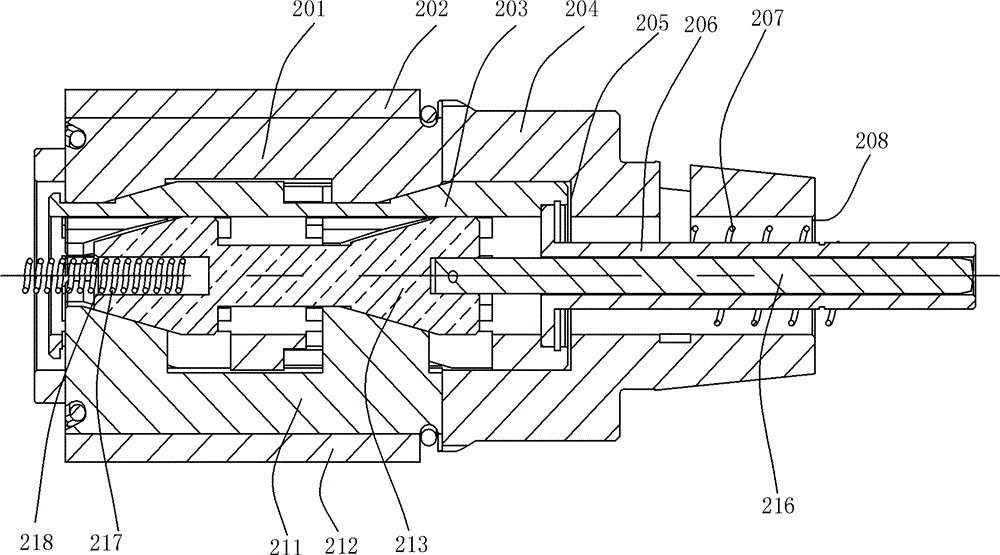

[0032] The so-called double-feed honing head is to use diamond honing rods or CBN honing rods and other high-hardness honing rods for rough honing, and honing rods such as GC abrasives for fine honing processing. The honing head is not replaced but in the same process. When completed, install two types of honing sticks on the same honing head in advance.

[0033] Such as image 3 As shown, the double-feed honing head includes a hollow cylindrical honing head body 204 , and the rear end of the honing head body 204 has a central hole 208 . There is a rough honing expansion mandrel 203 and a fine honing expansion mandrel 213 inside the honing head body 204, the rough honing expansion mandrel 203 is set on the outside of the fine honing expansion mandrel 213, the rough honing expansion mandrel 203 and the fine honing expansion mandrel 213 The expansion mandrels 213 can slide axially independently, and the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com